Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Supplier automatic PLC Control Cable Tray Roll Forming Machine 2018 new design made in China

Main Components:

| No. | Name | Quantity. |

| 1 | 5 ton Hydraulic decoiler | 1 set |

| 3 | Roller Leveller | 1 set |

| 4 | Servo feeding machine | 1 set |

| 5 | Punching Press machine | 1 set |

| 6 | Punching moulds | 4 sets |

| 7 | Roll forming machine | 1 set |

| 8 | PLC system | 1 set |

| 9 | Post cutting device( with 4 sets of blades) | 1 set |

| 10 | Collecting tables 3m | 2 sets |

| 11 | Toolbox | 1 set |

| 12 | Spare parts | 1 set |

Main Technical Details

1. Suitable Plate Material:

1.1 Material– thickness:0.8-1.5mm

1.2 Raw material: Galvanized steel and black steel sheets

2. Working Speed: 12meters / min

3. Forming Steps: 20 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: *90mm), thermal refining

6. Driven system: chain drive, shafts diameter 100mm

7. Main Power with reducer: 22KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 11KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan

13 Touch Screen—Beijing Kunlun Encoder--Omron, Japan

14. Electric parts--Schneider

15. Adjust the height by the motors and the rails, controlled by the PLC

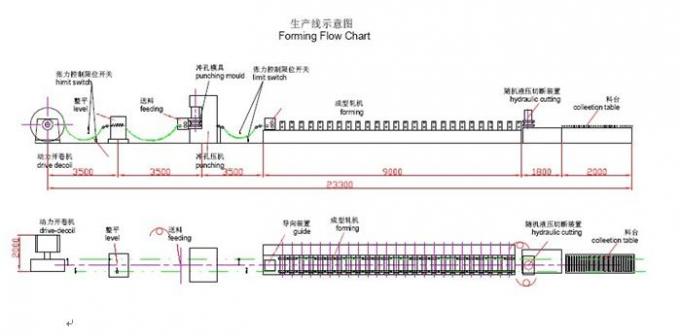

Work Flowchart:

Our service

(processes)

First step:

Designing. After order confirmation, we start to design the machine, such as the basement, structure, rollers, shafts, power, cutting device, programs and so on.

Second step:

The main parts, like rollers and shafts are produced by ourselves. We have several high-precision CNC lathe and other kinds of new machine tools, so that the quality and precision can be controlled.

Third step:

Assembling. The machines are assembled by technicians with years of experience, which can help workers improve the production efficiency and machine’s quality.

Fourth step:

Test. Raw material of different specifications are prepared for testing. And during test, long enough material is used. Because if the material is not long enough, some defects can not be exposed.

Five step:

Delivery. Because of the weight of machine itself, the packing is usually bare packing. Machine will be fixed inside container by steel wire, in order to make sure it won’t move during transportation and avoid any kinds of damage of machine and container.