Jiangsu Lebron Machinery Technology Co., Ltd. |

|

PLC Control Full Automatic Garage Door Guide Rail Forming Machine Durable High Efficiency

1. Description of Garage Door Guide Rail Forming Machines

The Garage Door Guide Rail Forming Machine is a roll former which can make various kinds shapes of Galvanized steel guild rail of doors for door industry.

The Garage Door Guide Rail Forming Machine is start from the unwinding of metal coils, entry the Garage Door Guide Rail Forming Machine after leveling, roll formed to specific section according to client’s design requirement, cut to length by hydraulic cutting device then stacking and packing.

The standard whole solution on the Garage Door Guide Rail Forming Machine is combined of uncoiler, hydraulic punching devices, stationary hydraulic shear device, main roll forming system, run-out tables and PLC system.

2. Main Components of Garage Door Guide Rail Forming Machine

| No. | Item | Quantity |

| 1 | Decoiler | 1 Set |

| 2 | Guide and Punch Rollers | 1 Set |

| 3 | Main Roll Forming System | 1 Set |

| 4 | Hydraulic Cutting device | 1 Set |

| 5 | Hydraulic Station | 1 Set |

| 6 | Run-out Table | 2 Sets |

| 7 | Control System | 1 Set |

3. Technical Parameters of Garage Door Guide Rail Forming Machine

| Suitable Material | Coil Type | GI, GL Coil |

| Coil Thickness | 0.7~1.8mm | |

| Coil Width | According to design | |

| Yield Strength | 250~350Mpa | |

| Decoiler | Decoiler type | Hydraulic |

| Weight Capacity | 8 Tons | |

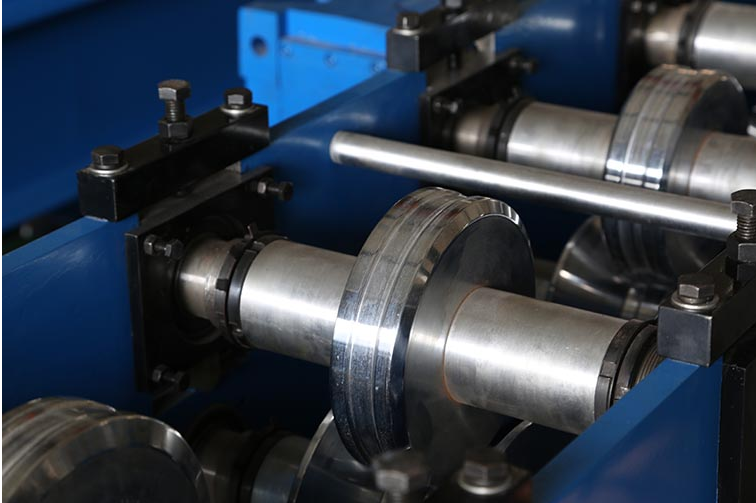

| Main Roll Forming | Forming Station | 16~20 stations |

| Roller Material | 45# Steel. Quenched. 0.05mm hard chrome coated | |

| Shaft Material | 45# Steel. Quenched. 0.05mm hard chrome coated | |

| Shaft Diameter | 50mm | |

| Drive Type | Chain drive | |

| Forming Speed | 8~12m/min | |

| Main Power | 5.5 Kw | |

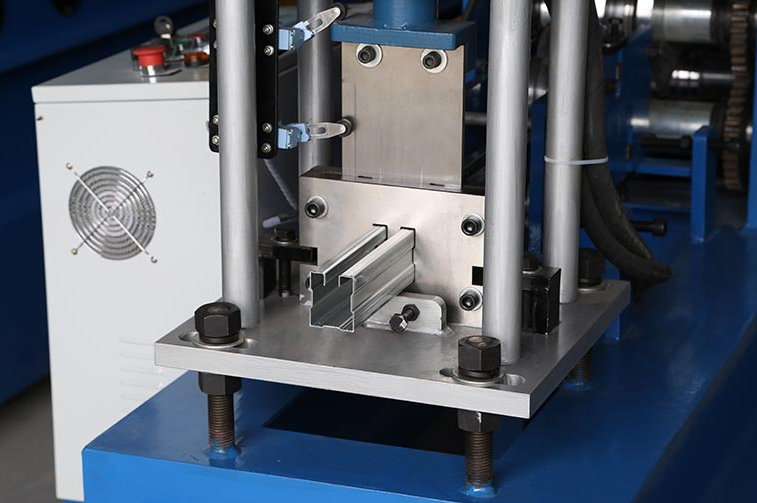

| Cutting device | Cutting Device | Hydraulic Cutting |

| Cutting die Material | Cr12MoV | |

| Cutting Tolerance | +/-1mm (10m) | |

| Hydraulic Station | 4 Kw, with 12Mpa pressure | |

| Electric System | PLC Brand | Panasonic |

| Converter | Yaskawa | |

| Encoder | Omron | |

| Reducer | Guomao | |

| Touch Screen | MCGS | |

| Electrical parts | Schneider | |

| Run-out Table | Type | No power with passive rollers |

| Function | Support the profiles after cutting | |

| Machine | Dimension | 3.5m*0.5m*0.8m (L*W*H) |

| Weight | 3.5 Tons |

4. Garage Door Guide Rail Sketch

5. After sale Service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.

6. FAQ

1. Q: What is the MOQ?

A: 1 set.

2. Q: What is the Delivery time?

A: Within 35 workdays.

3. Q: What is the Payment terms you can accept?

A: T/T or L/C.30% deposit,and before shipped we hope to receive the balance 70%.Also 100% L/C is accepted.

4. Q: What is the Warranty?

A: Within 2 years warranty.All of the technical personnel are ready to serve you at any time.

5. Q:Can you make the machine according to my design or photo type?

A: Yes.We have an experienced team for working out the most

suitable design and production plan for the machine that you are

going to book with us.

6. Q: How can we be assured that you will deliver us quality

machine with spare parts?

A:1. Customers to send the technical people to our factory for

checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

3.Good after-sales service, its free of charge during the warranty period.

7. Our Machine Advantage

1.Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

8. Packaging :

1. Tighten to container with steel wire rope and welded machine with container by angel iron

2. Main forming machine and un-coiler is naked(If you need we can also packed with water-proof plastic)

3. PLC contral system and motor pump are packed in wooden box with water proof paper coverage

9. Picture