Dongguan Xinbao Instrument Co., Ltd. |

|

Salt Spray Corrosion Environmental Test Chambers for Metal Plating / Coatings

Introduction

Salt Spray Corrosion Environmental Test Chambers for Metal Plating / Coatings is a climate simulation device that tests the corrosion of electronic equipment, metallic material, as well as some surface treatment--coating, galvanizing, organic/inorganic coating, anodizing treatment, rust-proof oil coating, etc. Performance indicators in line with requirements of GB / T5170.8 Electrical and Electronic Products, Environmental Testing Equipment, the Basic Parameters of the Test Method. The salt spray corrosion test chamber according to GB / T2423.17 Electronic and Electrical Products Basic Environmental Test Procedures Test Ka: Salt Spray Test Method for neutral salt spray test can also be used for acetic acid salt test.

Specification

| Model | XB-OTS-60 | XB-OTS-90 | XB-OTS-120 | XB-OTS-160 | XB-OTS-200 |

| Inner size (cm) | 60x45x40 | 90x60x50 | 120x80x50 | 160x100x50 | 200x100x50 |

| External size(cm) | 107x60x118 | 141x88x128 | 190x110x140 | 230x120x140 | 270x150x150 |

| Inside temp | Brine test method(NSS ACSS)50°C±1°C Corrosion resistance test method. | ||||

| (CASS)50°C±1°C | |||||

| Brine temp | 35°C±1°C 50°C±1°C | ||||

| Test chamber volume | 108L | 270L | 480L | 800L | 1000L |

| Brine chamber volume | 15L | 25L | 40L | 40L | 40L |

| Compressed air pressure | 1.00±0.01kgf/cm2 | ||||

| Spray volume | 1.0~2.0ml/80cm2/h (Collect at least 16 hours, the average) | ||||

| Test room relative humidity | 85%RH or more | ||||

| PH | 6.5~7.2 or 3.0~3.2 | ||||

| Spray method | Programmable spray (including the continuous spray interrupted spray) | ||||

| Protective system | 1.The over temperature of whole machine. | ||||

| 2.Automatically cut the power off when the water level of test chamber or pressure bucket is below the standard. | |||||

| 3. The entire machine is set with a timer and alert of overflow, electronic leakage, light circuit. | |||||

| Warranty | 12+2month(in view of transportation ,Customs be 2month),maintenance for lifelong | ||||

Design Standard:

Thermostatic control can be set under CNS, JIS, ASTM standard:

Ⅰ Humidity and salt spray test: NSS,ACSS

1) Temperature of test box: 35℃±1℃

2) Temperature of pressure bucket: 47℃±1℃

Ⅱ Corrosion resistance test: CASS

1) Temperature of test box: 50℃±1℃

2) Temperature of pressure bucket: 63℃±1℃

Supply system: the pressure is 1kg/cm²

Spray measurement 1-2mI(mI/80cm²/h)(average in 16 hours)

Spray way: Continuously.

Product Presentation

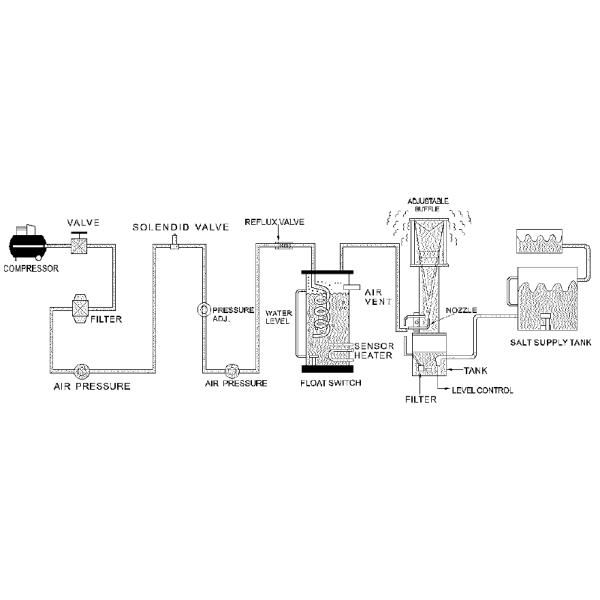

1. Salt Spray Test Chamber System Diagram

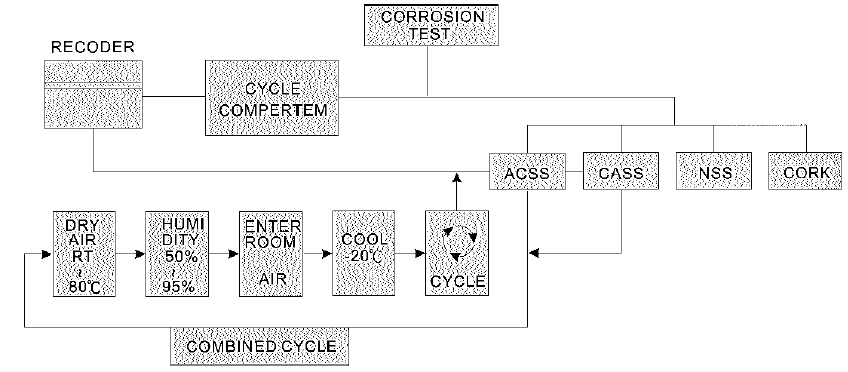

2. Combined Cycle Tester System Diagram

Please feel FREE to contact us if you have any needs.

Custom-made ASTM B117 NSS AASS CASS Salt fog Cabinet , salt spray test chamber