|

|

[China]

Trade Verify

Address: Room 804, 2nd Building, No.68 Luositang Road, Economic and Technological Development Zone, Changsha City, Hunan Province, P.R. China. 410100

Contact name:Aivin Ai

Changsha Tianchuang Powder Technology Co., Ltd |

|

Verified Suppliers

|

|

40L Industrial Vertical Planetary Ball Mill - High-Throughput Nano Grinding System

Industrial-Grade Processing Solution

Our 40L vertical planetary ball mill represents the pinnacle of production-scale grinding technology, specifically engineered for industrial nano powder manufacturing and advanced material processing. This heavy-duty system combines massive processing capacity with precision grinding performance, making it ideal for pilot-scale production and high-volume research applications.

Advanced Vertical Grinding Technology

The mill features an innovative vertical planetary configuration where four large-capacity grinding jars perform synchronized planetary movements. This unique vertical orientation optimizes energy transfer efficiency while maintaining exceptional grinding uniformity. The system generates powerful centrifugal forces up to 15G, enabling consistent particle size reduction to 100 nanometers with industrial-scale reproducibility.

Industrial Application Spectrum

This production-grade mill serves critical functions across multiple industries:

Battery material production (cathode/anode powders)

Advanced ceramic manufacturing (structural/functional ceramics)

Electronic component materials (MLCC, ferrites, varistors)

Metal powder processing (alloy development, additive manufacturing)

Pharmaceutical intermediate grinding (API micronization)

Nanomaterial synthesis (graphene, quantum dots, composites)

Technical Superiority

Production-Scale Capacity: 40L processing volume for industrial throughput

Precision Vertical Drive: Optimized gear transmission for consistent power delivery

Intelligent Control System: Programmable multi-stage grinding with process memory

Enhanced Safety Architecture: Triple-interlock protection system

Material Versatility: Supports both aqueous and solvent-based processes

Special Environment Options: Configurable for inert/vacuum operation

Industrial Reliability: Heavy-duty construction for continuous operation

Performance Advantages

The mill's vertical design offers 30% greater energy efficiency compared to horizontal configurations, while its balanced rotation mechanism ensures vibration-free operation even at maximum capacity. The system maintains laboratory-grade precision (±1% speed accuracy) while delivering production-scale output, with noise levels below 70dB for factory-floor compatibility.

Operational Benefits

Production facilities benefit from the system's ability to bridge R&D and full-scale manufacturing, maintaining nano-scale precision at industrial volumes. Research centers gain pilot-scale capabilities for material development and process optimization. The mill's combination of massive capacity, vertical efficiency, and process control makes it the ultimate solution for advanced material production.

Technical Features

| Technical Features | |

| Drive Mode | Gear drive and belt drive |

| Operate Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | Soil material≤3mm |

| Output Granularity | Minimum 0.1μm |

| Rotational Speed Ratio | /1/2 |

| Max.Continuous Operating Time | 72hours |

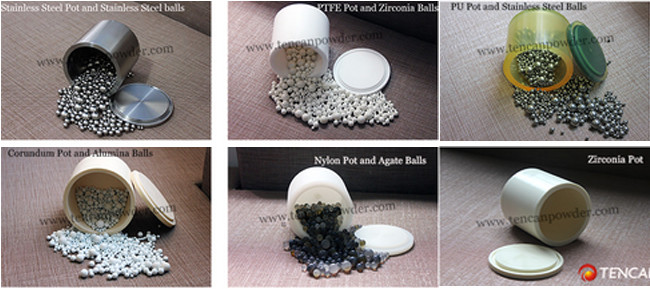

| Materials of Jar | stainless steel.agate,nylon,corundum,zirconia,etc |

Technical Parameters

| Main Parameters of Vertical Industrial Planetary Mill Ball (SquareType) | |||||

| Model | Power(KW) | Voltage | Dimension(mm) | Revolution Speed (rpm) | Rotation Speed (rpm) |

| XQM-20 | 4 | 380V-50Hz | 1200*750*920 | 25-215 | 50-430 |

| XQM-40 | 5.5 | 380V-50Hz | 1400*850*1160 | 20-195 | 40-390 |

| XQM-60 | 7.5 | 380V-50Hz | 1600*990*1250 | 27-174 | 40-260 |

| XQM-100 | 11 | 380V-50Hz | 1750*1140*1330 | 27-160 | 40-240 |

Accessories of Mill Jars & Balls

Available Mill Jars:

304 stainless steel mill jar, 316 stainless steel mill jar, tungsten carbide mill jar, agate mill jar, alumina ceramic mill jar(also called corundum mill jar), zirconia mill jar, nylon mill jar, polyurethane mill jar, mill jar (PTFE), and etc.

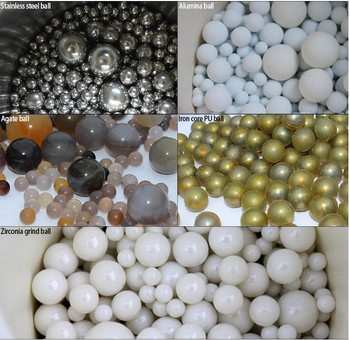

Available Mill Balls:

304 stainless steel mill balls, 316 stainless steel mill balls, tungsten carbide mill balls, agate mill balls, alumina balls, zirconia mill balls, and etc.