Hunan Kellyway Machinery Co., Ltd. |

|

Friction Kelly Bar for Bauer Soilmec Mait Sany XCMG Piling Rig in Foundation

Technical Parameter of Kellyway Friction Kelly Bars

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Friction Kelly Bars are used with pilling rigs for drilling in silt, clay and less dense sand and gravel.

Cases for Friction Kelly Bar

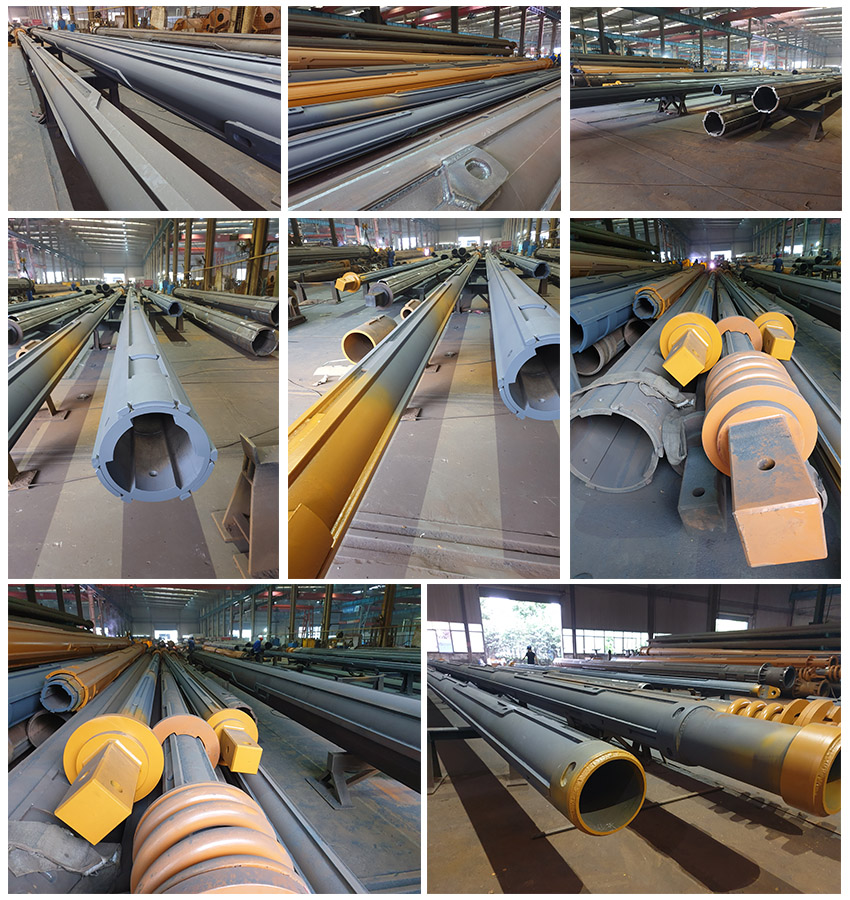

Factory Product Pictures

Shipping & Delivery

Jobsite

1. What is kelly bar?

Kelly bars are key components in the execution of boreholes by hydraulic rotary drilling rigs. Telescopic Kelly bars transfer torque and crowd force from the rotary drive to the drilling tool.

Kelly bars can be selected into friction and interlocking type. Friction kelly bars are properly defined by their frictional contact between rail of each element. Interloking kelly bars are indeed privided with drive ribs which are welded with lock devices in order to transfer the maximum torque to each scope.

2. Why choose us ?

Construction and welding manufacturing process of Kellyway kelly bars is by means of high quality materials and high mechanical features steel, provided with origin and quality certificates to guarantee long-life and reliability of the product after accurate engineering process.

3. How to use kelly bar?

Friction type kelly bar

A. Rotary table turns, keeping the drilling tool right on the hole position and making sure that the kelly bar keeps vertical during the whole drilling process.

B. Operate the rotary drive to rotate at a proper speed. The kelly bar transfers the torque from the rotary drive to the drilling tool and makes it rotate to drill.

Note: According to different stratums, it can not exceed 1m when using rotary drive to continuously pressurize.

C. Use winch to lift the kelly bar and drilling tool out of the hole.

D. Remove earth

E. Circulating until a drilling hole is formed.