Zhejiang Canaan Kaixinlong Technology Co., Ltd. |

|

Verified Suppliers

|

|

Overview of the machine:

Pharmaceutical Technology Pellet Filling Machine High Quality Capsule Filling Machine Hard Capsule Filling Machine

Technical parameters:

| Output | 1250Capsules/min |

| No.of segment bores | 9 |

| Suitable fof capsule | 00#-5# |

| Total power | 5.6Kw(Standard configuration) |

| Overall weight | 1200Kgs |

| Overall diemensions | 1085+(435)mm*1015(+252)mm*1880mm |

| Noise | ≤75DB(A) |

| Pressure | 0.4 ~ 0.7Mpa |

| Air consumption | ≤6m³ |

| Vacuum | -0.03 ~ -0.06Mpa |

| Filling error | ±2.5%~±5% |

The machine may make technical improvements without prior notice, and the attached picture shows the options that may be offered.

Finished capsule discharge station:

Use The finished capsules will be pushed out for collection. Principle The main component of the device is a discharge top rod that can

reciprocate up and down. When the upper and lower modules carrying

the closed capsule are rotated above the exit station and stopped,

the capsule is pushed out of the module hole. The capsule was then

blown into the outgoing hopper and slid into the stock barrel. |  |

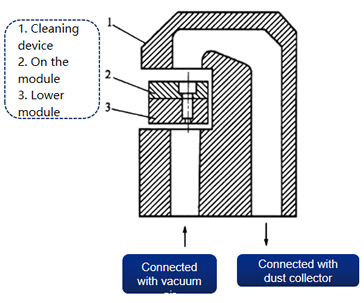

Cleaning station:

Use The cleaning unit cleans the module for access to the next cycle. Principle When the upper and lower modules are dragged under the main working

plate and parked at the cleaning station, they are placed at the

gap of the cleaning device. At this time, the compressed air is

opened, and the powder in the mold hole and the broken skin are

blown out of the mold hole from the lower direction of the lower

module. The vacuum suction system placed above the mold hole draws

it into the vacuum cleaner to keep the mold hole clean and to

facilitate the next cycle operation. |  |