Danyang Kaixin Alloy Material Co., Ltd. |

|

Verified Suppliers

|

|

KX Hyra50 Soft Magnetic Materials Soft Iron Light Rod On Soft Magnetic Alloy

Product Description and Application

The high permeability of the alloy can be used to manufacture magnetic core, inductor, sensor and etc magnetic components. Hiperco 50 alloy is an important magnetic material with a saturation magnetic induction of 1.56T. Hiperco 50 has low coercivity, which is easy to magnetize and demagnetize. Good processing property is easy to process and shape, which can be made into a variety of complex parts and components. Good thermal stability can maintain stable performance in high temperature environment.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Grade | Chemical Composition (Mass Fraction)(%) | ||||||||||

| C≤ | P≤ | S≤ | Mn | Si | Ni | Cr | Co | Mo | Cu≤ | Fe | |

| Hyra50 | 0.03 | 0.02 | 0.02 | 0.30~0.60 | 0.15~0.30 | 49~50.5 | --- | ---- | ---- | 0.20 | Rem |

| Density | 8.2g/cm3 |

| Fusing Temperature | 450℃ |

| Alloy Grade | Brinell Hardness (HBW) | Tensile Strength (MPa) | Specified plastic extension strength (MPa) | Elongation after fracture (A,%) | ||||

| Hard | Soft | Hard | Soft | Hard | Soft | Hard | Soft | |

| Hyra50 | 170 | 130 | 785 | 450 | 685 | 150 | 3 | 37 |

Alloy material is to undergo heat treatment,then the magnetic properties are in line with the following provisions, the return medium is generally pure hydrogen. If vacuum annealing is required, both parties shall negotiate and indicate in the contract.

| Alloy Grade | Heating Temperature | Soaking Time(H) | Cooling Process |

| Hyra50 | 1100℃ ~ 1180℃ | 3~6 | Cool to 600℃ at a speed of not more than 200℃/H and then cool to less than 300℃ at a speed of not less than 400℃/H |

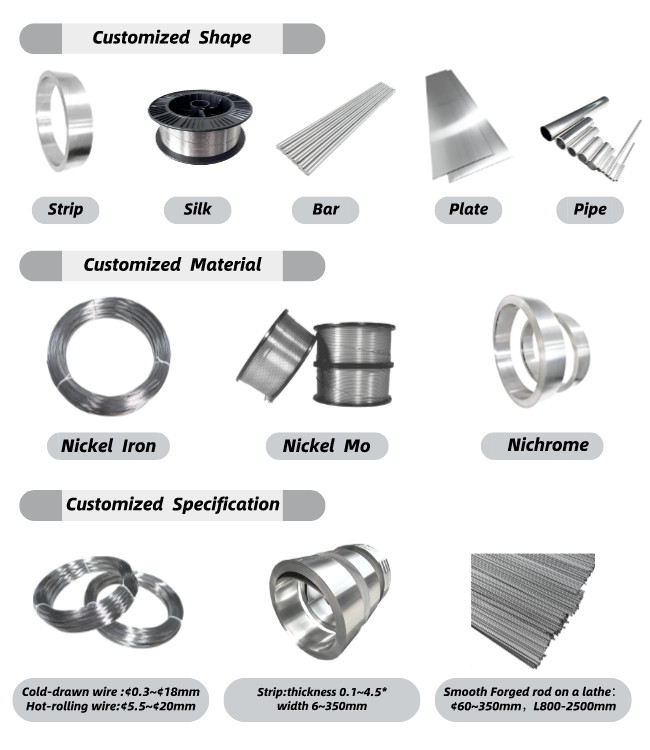

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |