CHANGZHOU JKONGMOTOR CO.,LTD |

|

Verified Suppliers

|

|

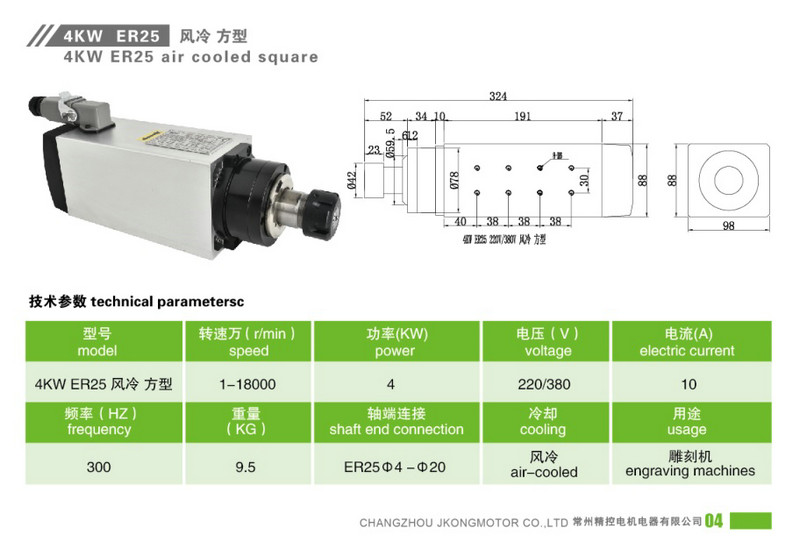

4KW ER20 ER25 Air Cooled Square CNC Spindle Motor 220V 380V 18000RPM / 24000RPM

CHANGZHOU JKONGMOTOR CO., LTD sells 2 types of spindle motors for CNC machine, wood carving/engraving machine, which are air cooled type spindle motor from 800W to 7.5kW and water cooled spindle motor from 1.5kW to 6kW. They features with simple and compact configuration, stable performance, reasonable price, high precision bearings, long service life and high speed to 24000rpm. Working at 3 phase 300Hz/400Hz 380V AC power supply, need to be equipped with VFD to use.

4kW Air Cooled Spindle Motor Specification

| Model | 4KW ER20 / 4KW ER25 |

| Power | 4kW |

| Phase | 3 phase |

| Speed | 1-18000/24000rpm |

| Voltage | 220/380V |

| Current | 10A |

| Frequency | 300Hz |

| Cooling Type | Air-cooled |

| Thermal Class | Class F |

| Warranty | Bearings for half a year, other parts for one year |

| Joint of Nose | ER20 (φ3.175-φ12.7) / ER25 (φ4-φ20) |

| Usage | Engraving machines |

| Weight | 9kg / 9.5kg |

Electrical Specification:

Matching inverter: 4kw inverter

Spindle motor features:

1) Imported bearings with good quality, long working life.

2) Application: Milling,Engraving,Drilling in all kinds of CNC

Router machine.

3) There are water cooling spindle , air cooling spindle and self

cooling spindle for your choose.

4) Every spindle motor must be passed polishing process, Improve

spindle concentricity to increase motor working life.

TIPS:

The spindle motor of woodworking engraving machine is an important component of woodworking engraving machine. The advantages and disadvantages of the spindle motor directly affect the processing speed and accuracy of the engraving machine. How to select high-quality spindle motor is very important. ATO summarizes the main points of woodworking engraving machine spindle selection for the reference of users:

1. If we pursue the efficiency of woodworking engraving machine, we should not only have a high speed, but also a large amount of knives. For example, when processing solid wood, we need a spindle motor with a power of more than 3KW.

2. Whether the spindle motor of woodworking engraving machine adopts high-precision bearings or not, if it does not use high-precision bearings, the performance is that the spindle motor overheated after long-term high-speed rotation, which affects the service life of the spindle motor.

3. Whether the spindle of woodworking engraving machine rotates at different speeds, especially at high speeds, the sound is uniform and harmonious.

4. Whether the radial force of the principal axis of woodworking engraving machine is applied. The main reference is whether the material with hard texture can be cut at high speed. Some spindle motors can only cut hard materials at very low speed, otherwise the performance of the motor will be seriously lost, which will affect the accuracy of the spindle after a period of time, or even cause faults.