Guangzhou JASU Precision Machinery Co., LTD |

|

Superior quality for final bottles

Most beneficial bottling line

| Item | Unit | Machine Type | ||

| ISB 1100AN-3 | ||||

| Injection Part | Screw Diameter | mm | 50 | |

| Screw L/D Ratio | L/D | 24:1 | ||

| Screw Speed | r/min | 0-150 | ||

| Theoretical Injection Capacity | cm3 | 481 | ||

| Injection Pressure | MPa | 176 | ||

| Max. Hydraulic Pressure | Kg/cm | 140 | ||

| The Actual Injection Quantity | g(ps) | 452 | ||

| Oz | 16 | |||

| Screw Stroke | mm | 245 | ||

| Clamping Part | Blow Clamping Force | KN | 150 | |

| Clamp Tonnage | KN | 600 | ||

| Wheel Diameter | mm | 1100 | ||

| Max. Height | PP, PET, PETG, Tritan, PS, PC | mm | 200 | |

| PC, PETG, Tritan, PS | mm | 220 | ||

| Open Vertical Mode Trip | mm | 570 | ||

| Others | Max. Pump Pressure | MPa | 16 | |

| Servo Motor | Kw | 22 | ||

| Mode Opening/Locking Motor (Double Pump) | Kw | 22 | ||

| Electric Power | Kw | 12.2 | ||

| Tank Volume | L | 420 | ||

| Dimension of Machine | m | 4.5*1.95*3.4 | ||

| Machine Weight | T | 9 | ||

| --Parameters are subject to change without prior notice. --Providing PC, PET, PP, PS, PETG, TRITAN screw barrels according to customers' requirements. | ||||

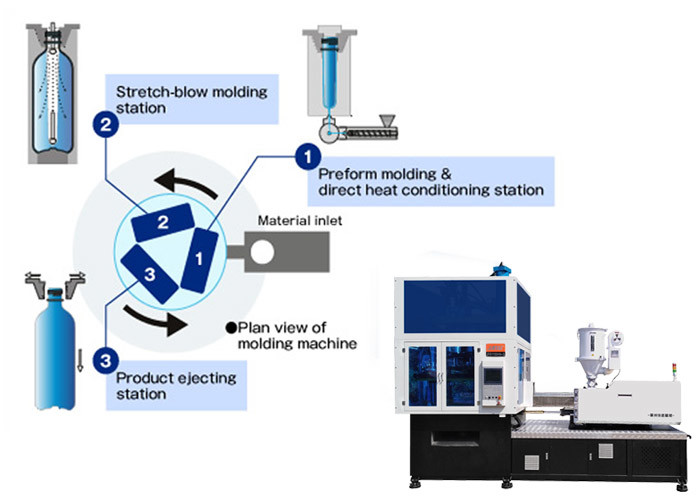

Application of PET Jar Making Machine

A large range of refined and essential designed platic blow molded bottles and jars are available from size 10ml to 2500ml.

Shapes: cylinder, jar, oblong, square, plain round, wide-mouth, oval, non-round, ultra-light etc.

PET bottle machines is used for producing various range of bottles that have numerous applications in different industries such as food & beverages, pharmaceuticals, personal care & cosmetics and many more.

JASU is the first PET Bottle Machine Manufacturers of Single Stage PET Blowing Machine

Absorbed the advanced technology from Japan and Germany.

Manufacturer/Direct Factory with production base takes 24000m2.

Own highly qualified technical staffs (20-30 persons) and R/D

center.

Obtained a number of technical patents.

Overseas sales increase 33% annually.

Market network throughout the country , and export to many

countries of East Europe, South America, South Africa etc.

Our machine enjoyed high reputation among customers.

Service technicians (holding visa and passport) are on call and

able to serve on site and instruct via voice and videos.

Mould and tooling, we have our own mold-making facility and mould workshop ourselves, advanced CNC machine and smart design engineers.

We can treat different materials and sizes of products.

Auxiliary machine,we will equip you with the necessary quality auxiliary machines to ensure the production plan running well.

Provide one-stop service.

Question & Answer

Q1: Are you a factory or trading company?

A1: We are established in 2003, a actual factory and manufacturer

in the line of injection blow molding machine for 18 years.

Q2: Where is your factory located? How can I visit you?

A2: Our factory is located in Panyu District, Guangzhou, Guangdong

Province, China, about 48 minutes by high-speed railway from Hong

Kong.

5 minutes driving away from Shiqiao subway station.

We can book hotel for you and pick you up from CAN BAIYUN airport

or Guangzhou south railway station.

Q3: How about the payment term?

A3: Advancement (subject to our marketing strategy and both

parties' discussion) and settle the balance payment prior to

delivery.

Q4: What about your main market?

A4: Our machines were sold well in China, also exported and enjoyed

a good reputation among customers from Europe, Russia, Southeast

Asia, Middle and South America, Africa etc.

Our customers widely spread over Russia, Italy, Poland, Turkey,

Netherlands, Sweden, Bulgaria, Brazil, Ecuador, Thailand, India,

Myanmar, Malaysia, Vietnam, Cambodia, Egypt, Algeria, South Africa,

Ivory Coast, Philippines, Bangladesh......

Q5: How does your factory do regarding quality?

A5: Quality is the most important principle. JASU people always

attach great importance to quality controlling from the very

beginning to the very end. Our factory has passed ISO and CE

certification. Patents and many other certificates obtained also

tells this.

Q6: What about warranty and do the engineers available to overseas?

A6: One year warranty. During this period, if you need any support

on installation, adjustment , operation or maintenance, our

engineers can go abroad to fix for you.

Q7: Others?

A7: We will request the working voltage and power frequency at the

buyer's side upon placing the order.

Contact us for PET Bottle Manufacturing Machine Cost