UL498 Plug And Socket Measuring Gauge For Retention Of Blades Test

Gauge list:

NO. | Product Name | Standard Figure | Model |

|---|

Old Version | New Version |

|---|

| 1 | Articulate probe with web stop | Figure 9.1 | Figure 9.1 | U8-F91 |

| 2 | Probe | Figure 10.1 | Figure 10.1 | U8-F101 |

| 3 | Flat probe | Figure 31.1 | Figure 31.1 | U8-F311 |

| 4 | Reference plug | Figure 69.1 | Figure 73.1 | U8-F691 |

| 5 | Typical test apparatus | Figure 69.2 | Figure 73.2 | U8-F692 |

| 6 | Improper insertion test blades | Figure 94.1 | Figure 98.1 | U8-F941 |

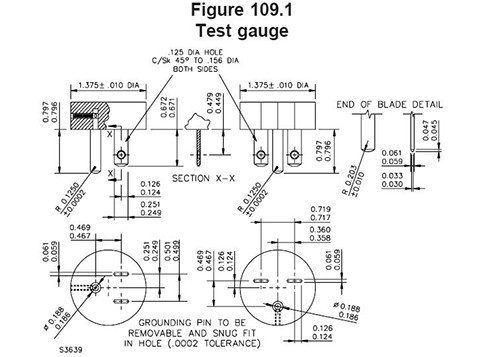

| 7 | Test plug | Figure 105.1 | Figure 109.1 | U8-F1051 |

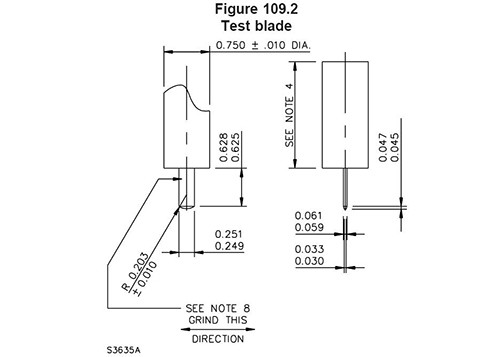

| 8 | Test blade | Figure 105.2 | Figure 109.2 | U8-F1052 |

| 9 | Receptacle test fixture | Figure 118.1 | Figure 122.1 | U8-F1181 |

| 10 | Push out tool | Figure 118.3 | Figure 122.3 | U8-F1183 |

| 11 | Bridge | Figure 118.5 | Figure 122.5 | U8-F1185 |

| 12 | Test pin A | Figure 119.1 | Figure 123.1 | U8-F1191 |

| 13 | Test pin B | Figure 119.2 | Figure 123.2 | U8-F1192 |

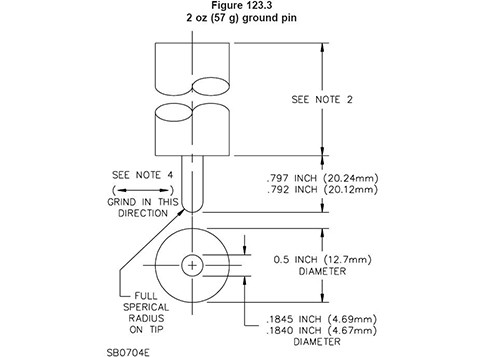

| 14 | 57g ground pin | Figure 119.3 | Figure 123.3 | U8- F1193 |

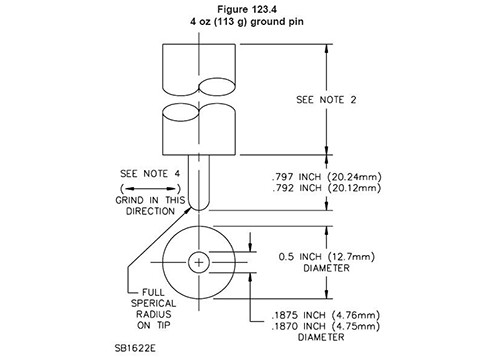

| 15 | 113g ground pin | Figure 119.4 | Figure 123.4 | U8- F1194 |

| 16 | No.14AWG test pin | Figure 129.2 | Figure 133.2 | U8-F1292 |

| 17 | Small test probe | Figure 132.1 | Figure 136.1 | U8-F1321 |

| 18 | Fixture for assembly security test | Figure 144.2 | Figure 165.2 | U8-F1442 |

| 19 | Standard grounding pin | Figure SD 5.1 | Figure SD 5.1 | U8-SD51 |

| 20 | Standard grounding pin | Figure SD 13.1 | Figure SD 13.1 | U8-SD131 |

| 21 | Oversize grounding pin | Figure SD 13.2 | Figure SD 13.2 | U8-SD132 |

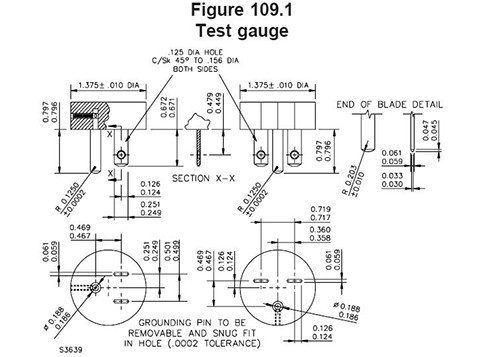

UL498-2012 Figure 109.1 1

UL498-2012 Figure 109.1 1

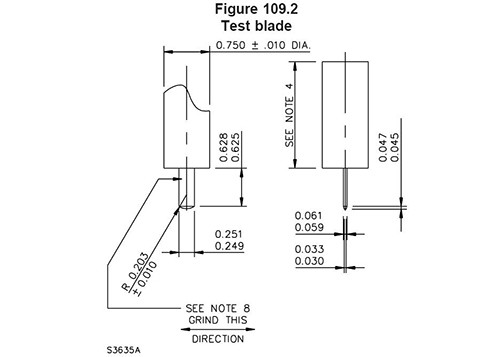

UL498-2012 Figure 109.2 1

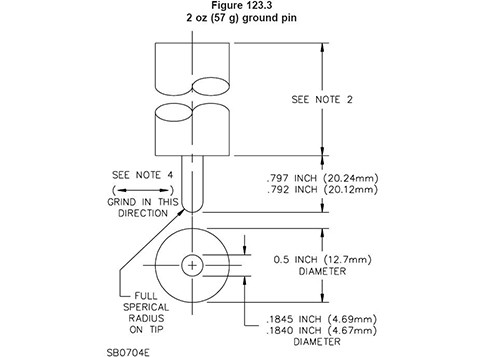

UL498-2012 Figure 123.3 1

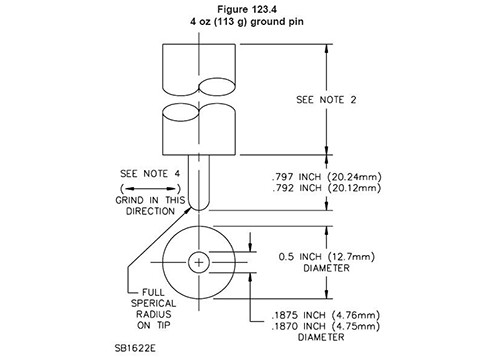

UL498-2012 Figure 123.4 1

109 Retention of Blades Test

109.1 A flush or self-contained receptacle having a 5-15R, 5-20R,

6-15R, or 6-20R configuration shall be

subjected to the retention of blades test described in this

Section.

Exception: A receptacle having a 1-15R, 5-15R, 5-20R, 6-15R, or

6-20R configuration and not of the

flush or self-contained type may instead be subjected to the

Retention of Plugs Test, Section 114.

109.1 revised November 16, 2012

109.2 Receptacles having the break-off tab, when provided, removed

from one nonidentified terminal are

to be subjected to ten conditioning cycles of manual insertion and

withdrawal of a standard gauge, see

Figure 109.1. Each of six devices is to be tested. The gauge is to

be configured as outlined in Table 109.1.

The force applied to insert the gauge for any of the conditioning

cycles is not to exceed 40 lbf (178 N).

The gauge is to have the dimensions indicated in Figure 109.1 but

is not to have holes in the outer ends

of the blades.

Figure 109.1 Test gauge

NOTES

1) Blades shall be made of tool steel, Rockwell Hardness C58 to

C60.

2) All sharp edges shall be removed to a radius of 0.016 to 0.020

inch. Ends of all flat blades bevelled as shown in the end of

blade detail.

3) Blade surfaces shall not exceed a 32 microinch finish grind in a

direction perpendicular to the major axis. Finish is to be

determined visually using a comparative method and 10 X optical

magnification.

4) All blade hole positions are located on the centerline of the

blades.

5) R designates radius. All dimensions are in inches.

6) Flat blade positions shall be modified to suit configurations

5-20 and 6-20.

Table 109.1 Test gauge configurations for conditioning

Device under test Test gauge No. of devices tested

5-15R 5-15P 6

5-20R 5-15P 3

5-20P 3

6-15R 6-15P 6

6-20R 6-15P 3

6-20P 3

109.3 The standard gauge is to be configured as shown in Table

109.2 using the line blades without

holes and with the grounding blade removed. The gauge is then to be

inserted in the receptacle and a

static 3 lbf (13.3 N) (including the weight of the gauge), which

tends to remove the gauge from the

receptacle, is to be applied for a period of 1 minute in a

direction normal to the plane of the face of the

receptacle. There shall not be more than 0.079 inch (2 mm)

displacement of the gauge.

Table 109.2

Test gauge configurations for retention testing

Device under test Test gauge No. of devices tested

5-15R 1-15P or 5-15Pa 6

5-20R 1-15P or 5-15Pa 3

5-20Pa 3

6-15R 2-15P or 6-15Pa 6

6-20R 2-15P or 6-15Pa 3

2-20P or 6-20Pa 3

a Test gauge having grounding blade removed.

109.4 The standard gauge is to be configured as shown in Table

109.3 using the line blades with holes

in the end and with the grounding blade in place. The gauge is then

to be inserted in the receptacle and

a force applied in a direction normal to the plane of the face of

the receptacle that tends to remove the

gauge. The static force required to withdraw the gauge shall not

exceed 15 lbf (67 N) (including the weight

of the gauge).

109.2. Each line contact shall be capable of withstanding for 1

minute a static 0.5 lbf (2.2 N) applied to

the test blade in a direction normal to the plane of the face of

the specimen and in a direction that tends

to remove the test blade, when the test blade is fully inserted in

the contact opening. There shall not be

more than 0.079 inch (2 mm) displacement of the test blade.

Figure 123.3

2 oz (57 g) ground pin

Material: Pin-Steel, Rockwell Hardness C58 to C60.

Handle – cold rolled steel

NOTES

1) The ground pin is to be fastened to handle in rigid manner.

2) Length not specified. Total tool weight 2 oz (57 g).

3) Axis of blade and axis of handle, must have combined

concentricity and axial alignment of 0.006 maximum at tip of pin.

4) The blade surfaces shall not exceed a 32 microinch finish grind

in a direction perpendicular to the major axis.

Finish is to be determined visually using a comparative method and

10 X optical magnification.

Figure 123.4

4 oz (113 g) ground pin

Material: Pin-Steel, Rockwell Hardness C58 to C60.

Handle – cold rolled steel

NOTES

1) The ground pin is to be fastened to handle in rigid manner.

2) Length not specified. Total tool weight 4 oz (113 g).

3) Axis of blade and axis of handle, must have combined

concentricity and axial alignment of 0.006 maximum at tip of pin.

4) The blade surfaces shall not exceed a 32 microinch finish grind

in a direction perpendicular to the major axis.

Finish is to be determined visually using a comparative method and

10 X optical magnification.

Application:

Shice equipment offers a wide range of gauge to meet the most

common standards including those from IEC, EN, UL, DIN, VDE and

others. Such standards require the checking of size &

definition etc. these gauges are constructed from senior stainless

steel and appropriate steel with a hardness of at least 52-58 HRC

and a roughness according to standard require. Each gauge is

supplied with a certificate of calibration.

Conforms To:

UL498