Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Insulating Glass Sealing Machine With Two Sealants Pumps Coating Glue

Introduction of insulating glass sealing machine

Full automatic insulating glass sealing robot machine is used to seal the second glues during making insulating glass units. The sealing robot has the same method with coating glass, however, the sealing robot used servo mortor and PLC to control the whole working, it improves working efficiency. The sealing robot can out put 500 - 800 pieces per day in 8 hours.

Function and feature:

1.Insulating glass sealing machine is suitable for glass deep

processing enterprise ,high automation, Reduce labor intensity,

save manpower, improve production efficiency

2. Whole machine adopt man-machine touch screen interface,with

memory function .

3.After coating sealant ,the glass edge and corner is full without

air bubbles , smooth surface, no need to pare the corner

4. Using two sets of independent sealant supply system ( including

the mixing device ), two kinds of sealants switch fast ,in

one-button operation easily (Model II)

5.The width of machine is 1.5m ,small floor area, save space

6. The third section can prestore glass to improve the efficiency

effectively

7.The smallest insulating glass size can be processed is 300*300mm

8.Equipped anti blocking device in the mixer

9. Servo control system adopts world famous brand (Japan YASKAWA ),

the performance is stable

10. Shaft transmission to make the glass being transferred smoothly

with accurate positioning.

11. Special V type transmission belt to avoid the sealant sticking

on the belt, ensure the glass edge clean ,V type Block is

changeable .

12. The spare parts are produced with high standardization and high

precision, ensure the machine can be used with long-term stability

13.Suitable for triple glazing .

14.Conveying wheel on backboard adopts embedded wheel ,to make sure the glass be transported smoothly

Operating notes:

Specification of Insulating glass sealing robot

| Model | LJTJ2540 |

| Voltage Power | 415V 13KW |

| Air Pressure | 0.5~0.7Mpa |

| Extruding pressure | 32Mpa |

| Max.Glass size | 2500*4000 |

| Min.Glass size | 400*300mm |

| Glass thickness | 12~56mm |

| Working speed | 5~40m/min |

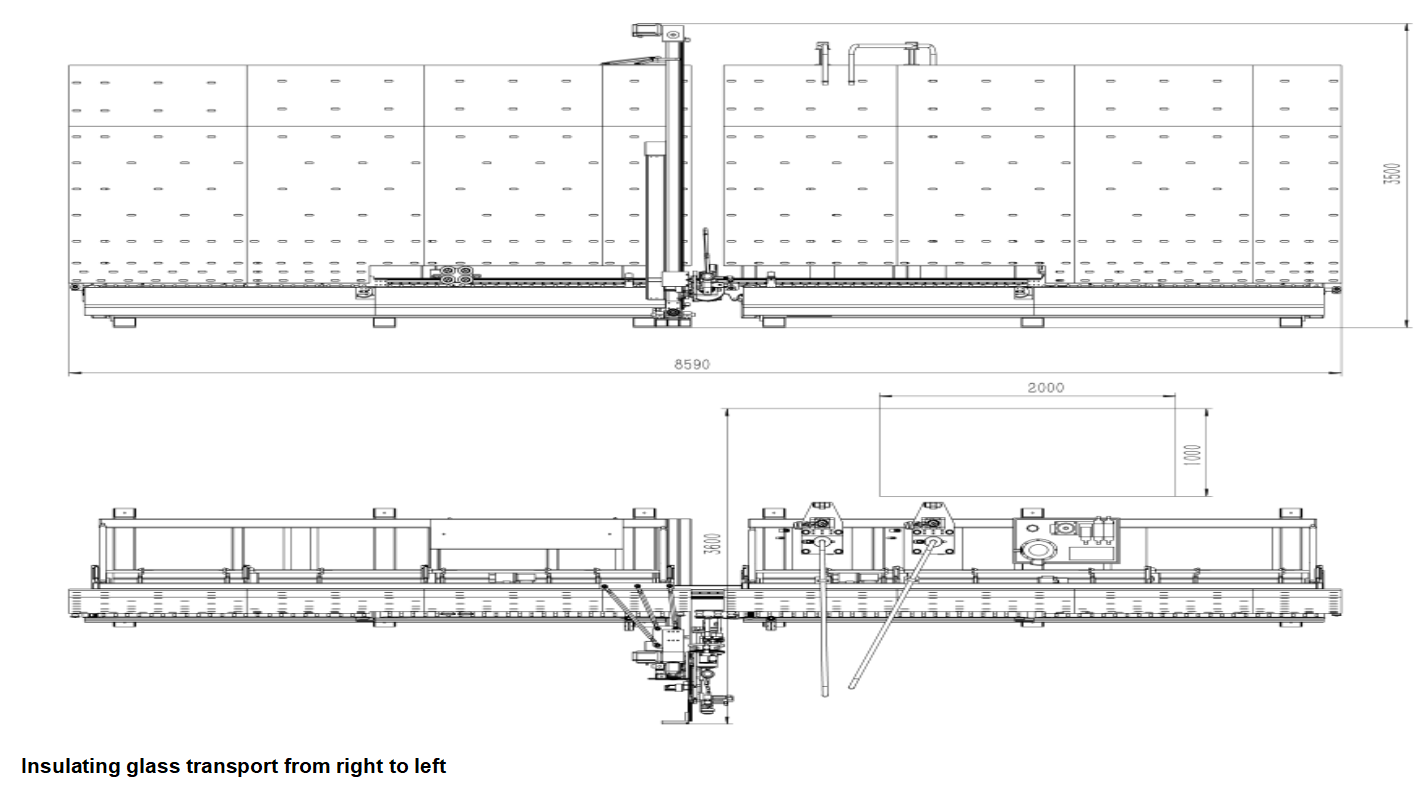

| Overall dimension | 11000*3600*3500mm |

Machine Noise :

| A-weighted sound pressure level | |

| Stand-by state | Working state |

| 50 db | 85 db |

Related product of LIJIANG GLASS

Main feature of the LJST02A silicone sealants spreading machine

• Imported motor system to improve equipment efficiency

• Sealant gun, stainless steel mixer

• High pressure protect device

• Anti-back flow control structure

• Mixed rate detector can control the rate of two kinds of glue

The silicone sealant-spreading machine LJST02A uses motor to control the sealing.

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |

Main feature of the sealant-spreading machine LJST03

• Use cylinder to provide power

• China sealant gun, stainless steel mixer

• High pressure protect device

• Anti-back flow control structure

• Mixed rate detector can control the rate of two kinds of glue

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mmI |

Silicone sealants is an ointment like material that solidifies into a tough rubber like solid once exposed to moisture in the air. It can be divided into deacetylation, dealcoholization, deamination and depropylation. Silicone adhesive is often used for glass bonding and sealing, so it is commonly known as glass adhesive. One component silicone glass adhesive is a kind of paste like material, which solidifies into a tough rubber like solid once exposed to moisture in the air.

Silicone structural sealants :

It is mainly used for structural or non structural bonding assembly between metal and glass of glass curtain wall.

2. It can connect glass directly with the surface of metal components to form a single assembly component, which can meet the design requirements of curtain wall with full or semi hidden frame.

3. Structural bonding and sealing of insulating glass.

Identification method:

There are many kinds of sealants: silicone sealant, polyurethane sealant, polysulfide sealant, acrylic sealant, anaerobic sealant, epoxy sealant, butyl sealant, chloroprene sealant, PVC sealant, and asphalt sealant. Identification of silicone adhesive mainly depends on the following properties: first, breaking strength (breaking force / cross-sectional area); two, bonding strength (pulling force / bonding area, except substrate damage); three, elongation at break (length / length of breaking); four, anti-aging ability; five, appearance (sub luminosity, particle, bubble); 6, Shape retention (no drawing, vertical surface not sagging); 7. Shelf life; 8. Curing time.

There is no good or bad, performance corresponding to the price, suitable for the best. Secondly, there is stability and sufficient quantity, which is the test of manufacturers. If the capacity of sealant is less than the marked capacity (Note: it is the capacity. This situation of sealant is very serious), this kind of sealant is eliminated first, there is a problem in the business ideas of such enterprises, and the products are not much better. (there are many problems, which proves that the control of production process is not strict). If the amount is large, the production stability of sealant should be considered.