Active Member

|

[China]

Address: Block B 1307, Green Square, Huaiyin District, Jinan China

Contact name:Rose

Jinan Lijiang Automation Equipment Co., Ltd. |

|

Insulating glass processing machines :

Desiccant filling machine : Desiccant filling machine with touch screen / manual molecular sieve filling machine

1. Big barrel (200L) for molecular sieve material

2. Protection device for machine head

3. Filling frame with arc-corner, the maximum radium size is 120mm

4. Large size for molecular sieve, from 1.0 - 1.5mm

5. Double heads

• Adopt Siemens PLC control system

• Touch screen interface, simple and visible

• The machine height can be adjusted according to the size of spacer frame

• Automatically loading and replenish molecular sieve

• Double tubes for unloading to increase filling speed

• Filling time can be adjusted

• Automatically drilling, filling and sealing

• Core parts are imported brands

• Fill large particle molecular sieve

| Max. frame size | 2000mm*2000mm (2500mm*2500mm) |

| Min. frame size | 300mm*250mm |

| Aluminum specifications | 6A- 27A |

| Production name | Desiccant filling machine |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1KW |

| Molecular sieve diameter needed | 0.5-0.9 mm or 1.0 – 1.5mm |

| Color | Blue , Green or Lisec color |

| Dimension | 1100mm*1100mm*3600mm |

LIJIANG’ new factory covers an area of 20000 square meters, has more than 100 employees, 6 people with middle and senior technical titles, 8 full-time technical R & D personnel, 3 production workshops (welding sheet metal workshop, machining workshop and assembly workshop) and technical R & D department, and has an independent international trading company (JINAN KATION). The production management and sales system of the enterprise adopts the advanced ERP and CRM management software in China to build an efficient, accurate, united and orderly high-end team.

LIJIANG GLASS's products mainly include: IG line series; Automatic sealing robot series; Low-e film edge deletion machine; Spacer bending machine series; Butyl extruder machine series; Desiccant filling machine and other auxiliary insulating glass machines. About 20 products are widely used in customized insulating glass industry, industrial aluminum alloy, building curtain wall, high-speed rail, elevator and advertising industry.

In 2016, we won the title of Jinan Golden Seed Enterprise and government subsidy by virtue of the first fully automatic butyl extruder machine with six axis independently developed.

In 2018, we won the title of national high-tech enterprise. During this period, we cooperated with many famous universities and the 53 Research Institute of the Ministry of ordnance industry to develop high-tech products.

Our corporate vision:

To make glass processing simpler and more intelligent, to be a high cost-effective specialty in the glass machinery industry, to better feed back and serve our customers, employees and society with better products and better services, and to make our life better!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD

Address: Block B 1307, Green Square, Huaiyin District, Jinan, China

Tell : 0086 0531-85960498 Fax : 0086 0531-87562846

Salesperson: Hermione (+86 18353163989 / +86 13001733235)

Email: sales01@lijiang-glass.com

Website : www.lijiang-glass.com / www.insulatingglassproductionline.com

Related product of LIJIANG GLASS

Double Glazing Glass Sealing Machine With Two Sealants Pumps Coating Glue

Introduction :

The full automatic insulating

glass sealing robot machine is used to seal the second glues during making insulating glass units. The sealing robot has the same method with coating glass, however, the sealing robot used servo mortor and PLC to control the whole working, it improves working efficiency. The sealing robot can out put 500 - 800 pieces per day in 8 hours.

Specification :

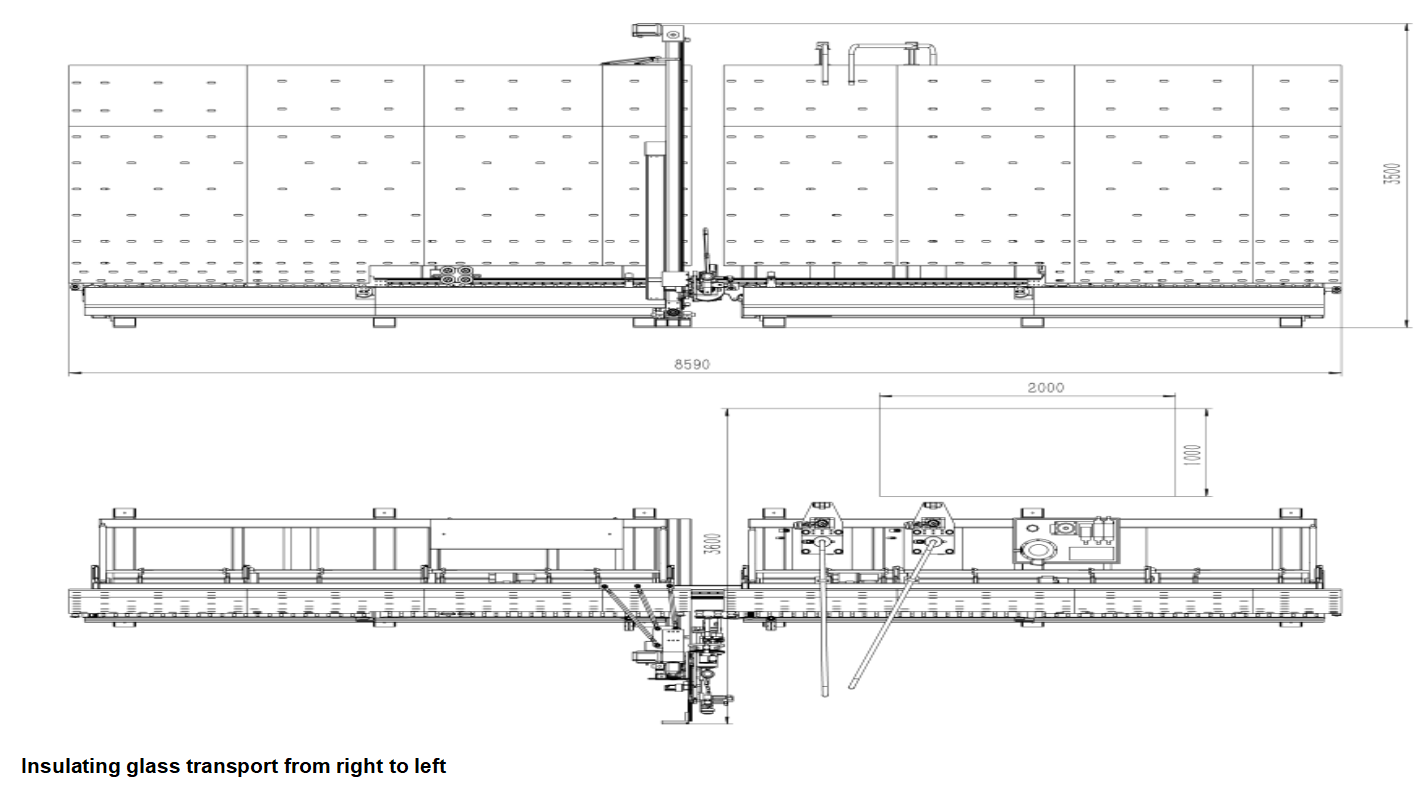

| Model | LJTJ2540 |

| Voltage Power | 415V 13KW |

| Air Pressure | 0.5~0.7Mpa |

| Extruding pressure | 32Mpa |

| Max.Glass size | 2500*4000 |

| Min.Glass size | 400*300mm |

| Glass thickness | 12~56mm |

| Working speed | 5~40m/min |

| Overall dimension | 11000*3600*3500mm |

Machine Noise :

| A-weighted sound pressure level | |

| Stand-by state | Working state |

| 50 db | 85 db |

Function and feature:

1.The machine is suitable for glass deep processing enterprise

,high automation, Reduce labor intensity, save manpower, improve

production efficiency

2. Whole machine adopt man-machine touch screen interface,with

memory function .

3.After coating sealant ,the glass edge and corner is full without

air bubbles , smooth surface, no need to pare the corner

4. Using two sets of independent sealant supply system ( including

the mixing device ), two kinds of sealants switch fast ,in

one-button operation easily (Model II)

5.The width of machine is 1.5m ,small floor area, save space

6. The third section can prestore glass to improve the efficiency

effectively

7.The smallest insulating glass size can be processed is 300*300mm

8.Equipped anti blocking device in the mixer

9. Servo control system adopts world famous brand (Japan YASKAWA ),

the performance is stable

10. Shaft transmission to make the glass being transferred smoothly

with accurate positioning.

11. Special V type transmission belt to avoid the sealant sticking

on the belt, ensure the glass edge clean ,V type Block is

changeable .

12. The spare parts are produced with high standardization and high

precision, ensure the machine can be used with long-term stability

13.Suitable for triple glazing .

14.Conveying wheel on backboard adopts embedded wheel ,to make sure the glass be transported smoothly

Operating notes:

When start working ,it need to wait the hydraulic pressure is stable ,then start extruding sealant on the first glass so as to avoid sealant output not stable.