Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

1. Touch-screen operation, simple and practical

2. Auto-measure the width of spacer, nozzle automatic positioning

3. Auto-centering and auto-clamping

4. The bigger wheel help to coat the arc frame

5. Coating nuzzle is Teflon brand ,non-stick coating

6. The coating speed is up to 47m/min,saving materials up to 30%,( 5g/m)

7. The crossbeam height is easy to adjust,we can control the height of butyl

8. The special part controls both sides of nozzle opening and closing at the same time

9. Alarm device when use out of butyl and easy to load butyl

10. Pre-heading function,set a regular time before working time

11. Glue cylinder Adopt the upright structure, easy to change butyl.

12. Automatic filter function Automatically filter debris, keep spreading evenly.

13. Hydralic and Pneumatic supercharging pump ,German MAXIMATOR brand

14. Pressure release valve German HAWE brand ,high pressure resistance ,keep the butyl well proportioned

15. Pneumatic component Taiwan Airtac

16. Japan OMROM Relay

Tech parameters of Automatic hot melt Extruder Machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 0-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 750kg |

Equipment details of Automatic Butyl Extruder Insulating Glass machine

Germany Siemens parts

Butyl extruder machine Adopt German brand Siemens PLC, stable performance.

KINCO Touch Screen

Use toubh screen operation ,simple trial,Clear interface, Simple operation, Smart touch screen,Updated programming.

Germany HAVE Valve

High speed butyl extruder machine Adopt Germany’s Harvey valve, more stable performance.

Alarm system

Adopt Automatically alarm system, reminding adding butyl.

Glue cylinder

The rubber cylinder adopt the pull-up structure, which is convenient for changing butyl.

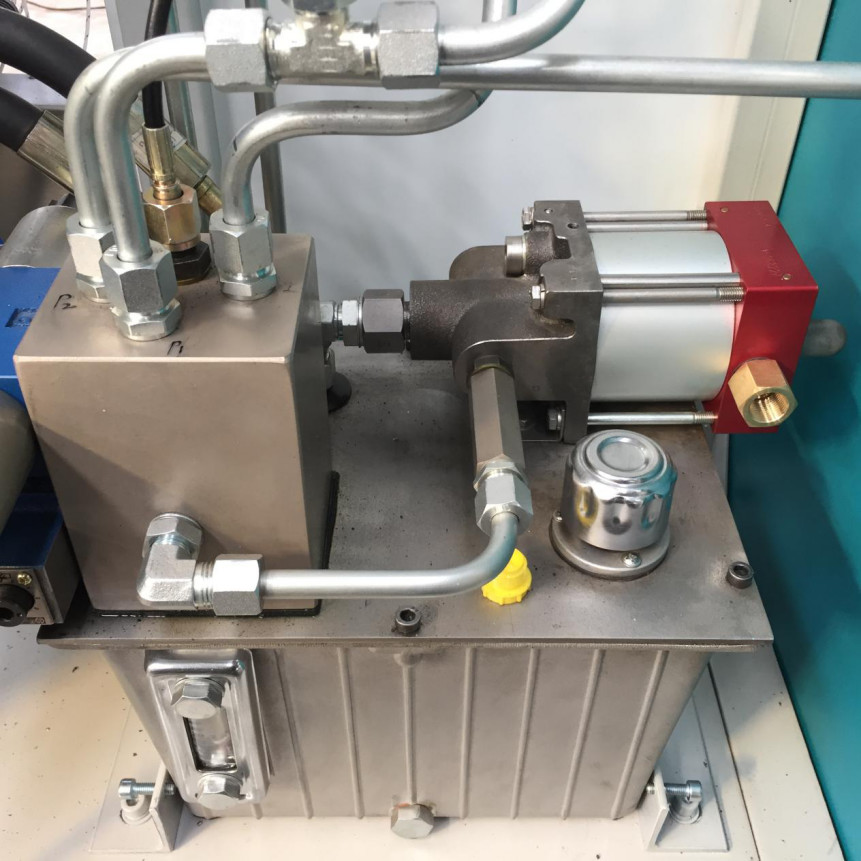

Germany Maximator Cylinder

Super charging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

Adjust the glue putput automatically according to the speed change

The height adjustment of beam is convenient,effective to solve the provlem of white line

Optional functions of Automatic butyl coating machine:

200L glue cylinder is optional

Related Products of LIJIANG GLASS

1.Butyl Extruder Machine LJTB 03

Main feature

• PLC control system, touch screen interface

• Frequency control system

• Arc frame coating structure

• Imported pneumatic and hydraulic supercharging system

• Automatic centering and clamping structure

• Loading capacity up to 14KG, saving time for feeding glue

• Adopt five steps to control convey

• Preheating function,glue cylinder limit function,alarm system

• Covey and gluing mechanism adopts the latest design

Technical data

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Aluminum spacer width | 6A-27A |

| Speed | 0-40m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5KW,50HZ |

| Dimension | 2600×680×1100mm(L×W×H) |

| weight | 650kg |

2.Desiccant Filling Machine LJGZ 2020A

Technical data

| Max frame size | 2000mm*2000nn (2500mm*2500mm) |

| Min frame size | 300mm*250mm |

| Aluminum specifications | 6A - 27A |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1.5KW |

| Molecular sieve diameter needed | 0.5-0.8mm |

| Dimension | 1650mm*1100mm*3600mm |

3.Automatic Aluminum Spacer Bending Machine LJZW2020