Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

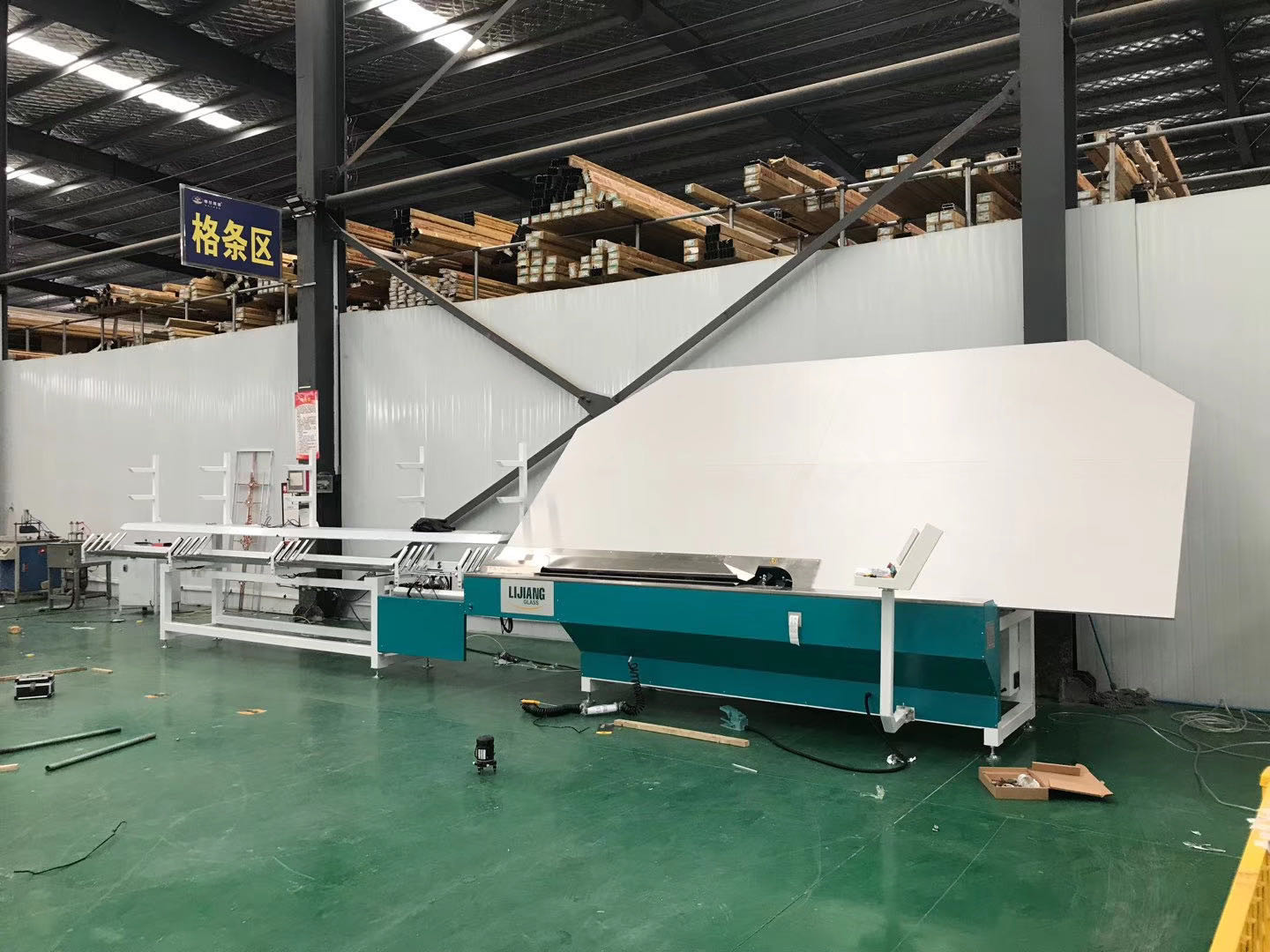

Auto aluminum Spacer Bending aluminum spacer bending cutting

machine Aluminum Spacing Bar Bending Machine

Automatic spacer bending machine LJZW2020

Automatic spacer bending machine is a special equipment for making

aluminum frames of insulating

glass, which replaces the traditional fabrication technology.

Automatic spacer bending machine can

make a variety of convex polygonal aluminum frames by one aluminum

strip in one time, thus strengthening

the strength of the aluminum frame, making the sealing effect of

the insulating glass more better.

Technical data of aluminum bending machine

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Electrical parameters of edge bending machine

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | GERMAN SIEMENS | Solenoid valve | Taiwan AIRTAC |

| Servo driver | GERMAN SIEMENS | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

² Equipment details of industrial bending machine

FAQ of glass bending machine

Q: What is the system of Kation’s after sale service?

A: Kation has its own special system for the service, we make a

“tree of knowledge”for guiding customer

to find the usual problem and the answer when customers meet.

Q: What is the details of the after sale service?

A: Step1: Notice before installation

Step2 : Confirm before installation

Step3: On-site installation

Step4: On-site debugging

Step5: On-site training

Step6: Client sign

Step7: On-line service

Step8: Technical service

The company is committed to building high-end insulating glass

machinery and equipment

by learning from famous experts, establishing the research and

development centers, cooperating

with domestic and foreign well-known enterprises, importing

advanced technology and so on. Now,

our friendly partners include North Glass, Xin Fuxing, Yaohua,

Dalian Huaying, Beijing Guanhua,

Shanghai Hao Jing, Sichuan Li Hehua and other well-known

enterprises. Since the establishment

of the company, our products have been exported to Europe, America,

South America, the Middle

East, Southeast Asia, India, nearly 30 countries and regions. At

the same time, our company worked

with the well-known domestic research institutes, such as the North

China Industrial Group, Shandong

University and others, to constantly improve the level of technical

research. So far, we have independently

produced the vertical automatic IG production line with filling gas

on line, the vertical IG sealing robot, the

automatic spacer bending machine, the automatic desiccant filling

machine and the new fully automatic

butyl extruder machine, its technology and quality have reached the

highest leading level in China.