Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

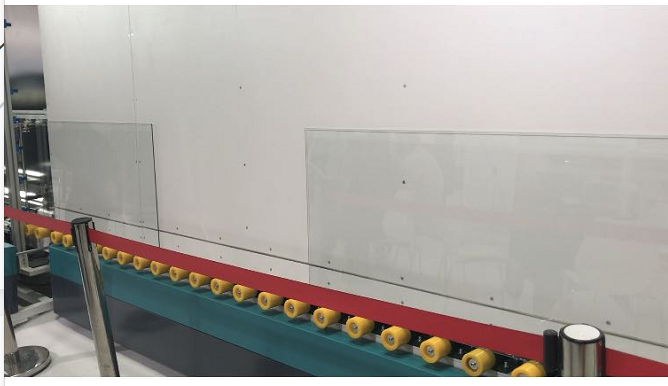

The advanced of pressing and filling two IG units:

| Max. glass size | 2500mm*3500mm |

| Max glass size for filling gas | 2500mm*3200mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

1. Minimum size : 280mm*400mm / Maximum size : 2500mm*3500mm

2. Double / triple / step (3 or 4-sided) / glass with low-e film

3. Some shaped glass

4. Glass with filling even argon gas

Jinan Lijiang Automation Equipment Co., Ltd specializes in the R & D

and manufacturing of automatic insulating glass machinery, with a

registered capital of 20 million RMB. Domestic friendly partners

include nearly one thousand customers, such as North glass,

Xinfuxing, Yaohua, etc.

The products have been exported to Europe, the United States, the Middle East, Southeast Asia, South America,Romania, Bulgaria, Span and other countries (about 30 countries) of the world. There are about ten agencies, such as North America, South America, Europe, Southeast Asia, the Middle East, South Korea, etc. At the same time, we have set up branches in New Delhi, India. At present, the export of products accounts for more than 50% of the company's total sales.

LIJIANG’ new factory covers an area of 20000 square meters, has more than 100 employees, 6 people with middle and senior technical titles, 8 full-time technical R & D personnel, 3 production workshops

(welding sheet metal workshop, machining workshop and assembly workshop) and technical R & D department, and has an independent international trading company (JINAN KATION). The production management and sales system of the enterprise adopts the advanced ERP and CRM management software in China to build an efficient, accurate, united and orderly high-end team.

Our corporate vision:

To make glass processing simpler and more intelligent, to be a high cost-effective specialty in the glass machinery industry, to better feed back and serve our customers, employees and society with better products and better services, and to make our life better!

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD

Address: Block B 1307, Green Square, Huaiyin District, Jinan, China

Tell : 0086 0531-85960498 Fax : 0086 0531-87562846

Salesperson: Hermione (+86 18353163989 / +86 13001733235)

Email: sales01@lijiang-glass.com

Website : www.lijiang-glass.com / www.insulatingglassproductionline.com