Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Higher working efficiency Insulating glass production line double glazing glass machine

1, Insulating glass production line Introduction

About the IG line only need focus on the two part -WASHING DRYING PART AND PRESSING PART .All other part just conveyors and assembly, no much technology, so please focus on that two .

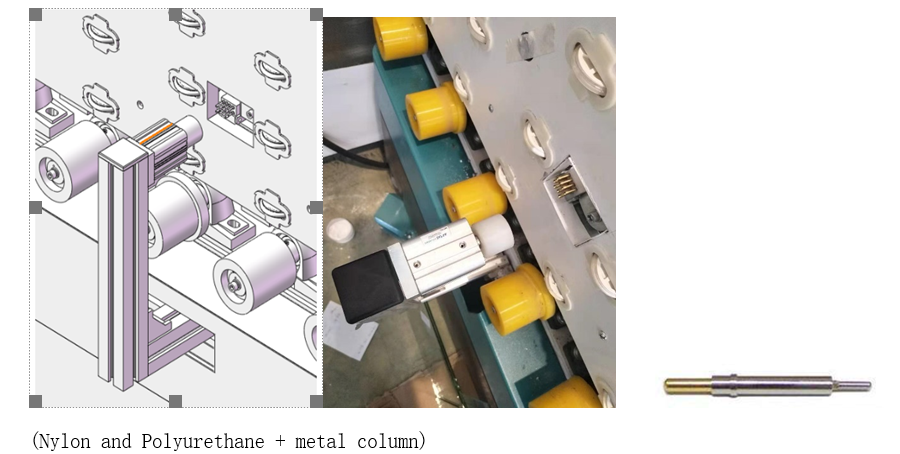

1, To Avoide the low-e Glass put inverse side and Leave wheel marks or scratch low-e Coating

We use coating inspection -metal film conductive (other company use Photoelectric detection,

hard to recognize for higher transparent)

2, Three pairs soft brushes can wash low-e glass and normal glass , the diameter is less than 0.1mm.

3, Materials are stainless steel.

4, Air knife is float design , it always keep the right and suitable distance 3mm

between the glass surface and air knife (Same like LISEC structure ) check the following picture. (3mm is the best drying distance)

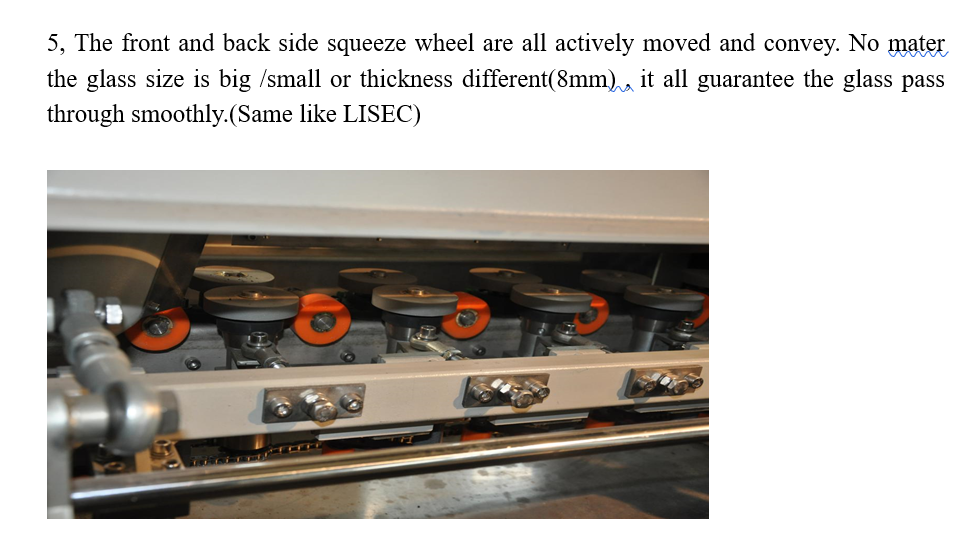

5, The front and back side squeeze wheel are all actively moved and convey. No mater the glass size is big /small or thickness different(8mm) , it all guarantee the glass pass through smoothly.(Same like LISEC)

Main Parameter

| Washing speed | 10~15m/min |

| Max.working speed | 45m/min |

| Washing glass thickness | 3~15mm |

| Max.insulating glass thickness | 80mm |

| Conveyor height | 500mm |

| Min.glass size | 450×280 |

| Max.glass size | 2500×4000

|

| Max.glass size | 2500*3500mm(LJBZ2535)Gas fillier line :2500*3200mm |

| Min.glass size | 280*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 40mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed: | 48m/min |

| Washing brushes | 3 pairs |

| Water supply: | Water consumption:0.5t/h conductivity:≤50μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P380V 50HZ 34KW |

| Dimension | 23500*3500*3700mm |

Main Products

Vertical Insulated Glass Produce Line for double glass production line

Auto Sealing Robot for double glass production line

Sealant Spreading Machine for double glass production line

Low-E Glass Washing &Drying Machine for double glass production line

Smart Edge Deleting Machine for double glass production line

Automatic Spacer Bending Machine for double glass production line

Automatic Desiccant Filling Machine for double glass production line

Butyl Extruder Machine for double glass production line

Glass Edge grinding Machine for double glass production line

Spacer Cutting Machine for double glass production line

Sealing gun Freezer for double glass production

Rotated Sealant Spreading Table double glass sealing

Argon Gas Filling Machine double glass

Exhibition show