Hunan Speed Carbide Tools Co.,Ltd |

|

Verified Suppliers

|

|

CCMT 1204 Indexable Carbide Turning Inserts CCMT120404-HM for Steel

Advantages:

Specification:

| Brand | Speed |

| Model | CCMT120404, CCMT120408 |

| Color | yellow, copper, black, blue , colorful coating |

| Workpiece | Steel, stainless steel, cast iron, Aluminum and etc., |

| Type | Turning Inserts |

| Package | 10pcs/box |

| Coating | pvd, cvd coating |

| Weight | 0.015kg |

| Usage | External Turning tool |

| Hardness | 20-65HRC |

| Material | Tungsten Cardide Inserts |

| Processing Type | Medium Cutting |

Application:

Our CCMT tungsten carbide Turning Inserts adopts imported coating

to ensure good stability of cutting edge, the blade has smooth chip

removal, higher hardness, sharp edge finish, good toughness,

long-lasting wear resistance, and economic efficiency,high edge

strength, low cutting resistance, high temperature resistance,

thermal shock resistance and oxidation resistance. The unique

coating process, fine and smooth, no drip marks, reduce surface

friction, so that the cutting resistance is smaller. And the

carbide inserts are sharp and thick, so that the cutting speed is

fast but not easy to break. It has wide range of application,

applicable to step surface processing, model profiling processing,

grooving cutting, slope processing, and could to be processed alloy steel, soft steel, carbon steel, medium steel, stainless

steel, cast iron, titanium alloy,

please send me your requirements to us, we will recommend the best

suitable grade.

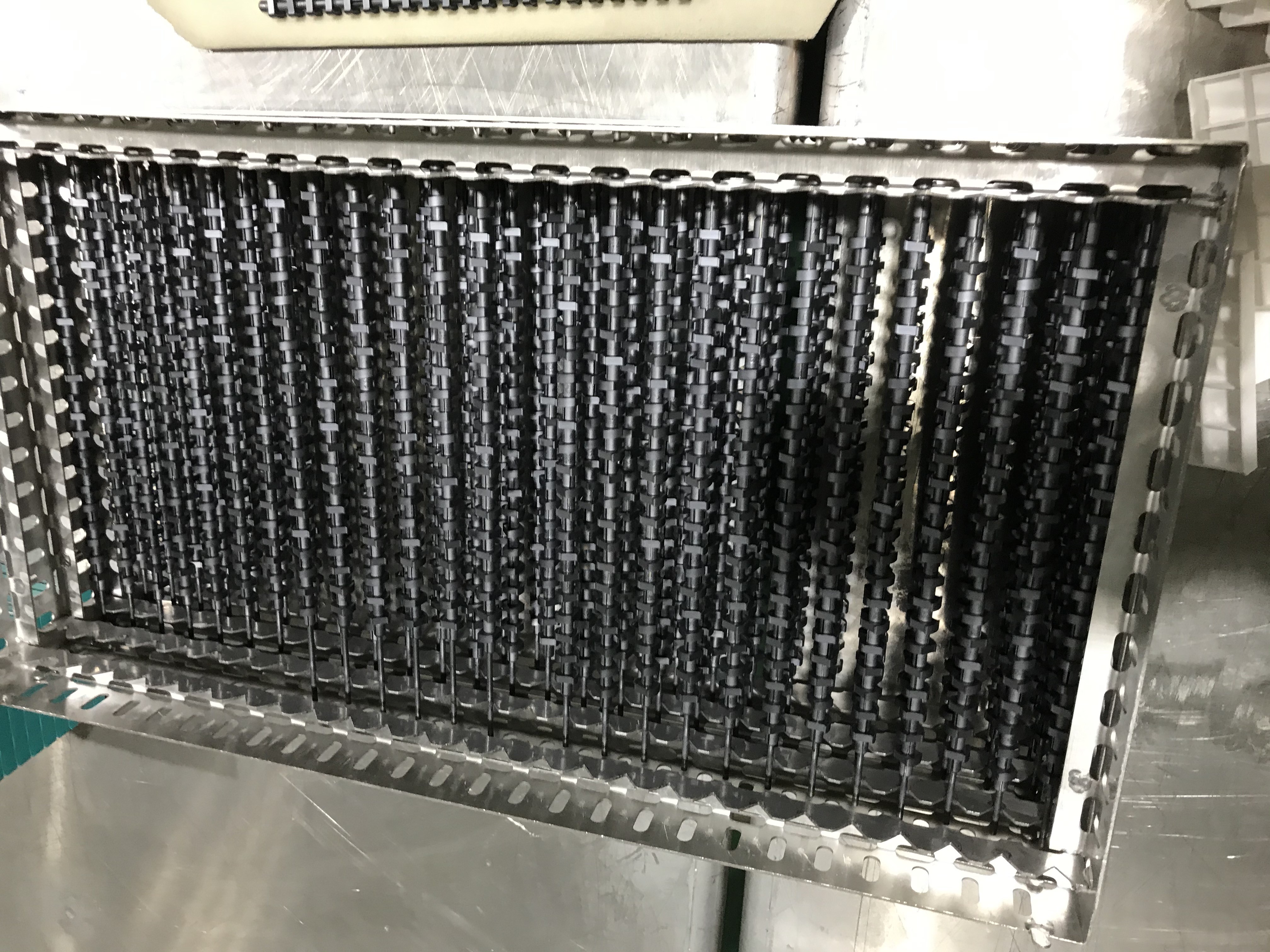

Products Detail:

Details:

1. Our perfect edge treatments, every pieces can stand the test.

2. Longer tools service life improving your working efficiency.

Company Profile

Hunan SPEED Carbide Tools Co.,Ltd is a professional supplier of Carbide, Inserts,Including Turning Inserts,Milling Inserts,Grooving Inserts,Threading Inserts,U drill lnserts, Aluminum Inserts and Cermet inserts etc. Located in ZhuzhouHunan, which is the biggest tungsten carbide tools city near ZCCCT, We provide various and efficient delivery ways. Our factory covers and area of 2,000sqm and has more than 100 staff members who are professional and willing to grow up with you.

Below is our factory and warehouse, we use

1. 100% virgin raw material + Germany DORST machine make perfect quality

2. each piece of insert have 3 times checked before shipment.

3. each piece will be finely grinding piece by piece

Feel free to contact if you want a factory show.

Note:

1. Carbide grooving inserts shall not be bumped or dropped on the ground and please be handled with care.

2. Before installing the carbide grooving blade, please confirm the performance and use of operation table, and the cutting direction indicated by the arrow of the blade is consistent with the rotation direction of the operation table. Please pay attention to don't install in the opposite direction. The wrong installation direction may cause the blade serrations to fall off, in case of accidents.

3. After installation, it is necessary to confirm whether the center hole of the carbide grooving blade is firmly fixed on the flange of the saw table. If necessary, put on a spacer, then, push it lightly by hand to confirm whether the blade rotates eccentrically.

4. When using, do not exceed the specified high speed.

5. When not using, please hang the blades upright on a dry rack.

FAQ:

1. Which shipping method do you usually use?

We usually send goods by express

For large amoun twe can send by air or by sea

We also can send products to your forwarder in China

2.When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you

are very urgent to get the price, please call us or tell us by

email or online chat so that we will regard your inquiry priority.

3.How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the

samples will be ready for delivery in 3-7 days. The samples will be

sent to you via express and arrive in 3-5 workdays. You can use

your own express account or prepay us if you do not have an

account.