OUCO (Wuxi) Injection Molding Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Plastic Injection Molding Machine CWI-2100S Features:

1. All parts are provided by well-known domestic parts processing factories, and the quality inspection is strictly controlled.

2. Two-plate mold clamping structure, fast mold moving speed, effectively shortening the production cycle, good overall rigidity, and small mold deformation.

3. The clamping mode adopts four-cylinder direct locking structure, stable high pressure, accurate and reliable parallelism, accurate and adjustable clamping force, which effectively protects the mold and prolongs its service life.

4. Automatic mold adjustment adopts computer logic operation data collection, which effectively ensures the reliability of mold locking.

5. The injection platform adopts linear guide rails to ensure stable and accurate injection and high repeatability.

6. Adopt high-response servo pump power system, flow and pressure closed-loop control. Fast response, effectively reducing energy consumption.

7. The hydraulic system adopts hydraulic components of well-known Japanese brands, and is equipped with plug-in logic valve oil circuit as standard, which effectively improves the system response speed

Product Paraments

| CWI-2100S | ||||||||

| 机型 | 2100S Ⅲ | |||||||

| 合模装置 | 锁模力 Kn | Clamping Force | 21000 | |||||

| 拉杆间距 mm | Space Between Tie-bars | 1800×1600 | ||||||

| 开模最大开距 mm | Clamping Stroke | 3700 | ||||||

| 最大模具 mm | Mould Thickness Max | 1700 | ||||||

| 最小模具 mm | Mould Thickness Min | 800 | ||||||

| 模板尺寸 mm | Size of Platen | 2620×2420 | ||||||

| 顶出长度 mm | Ejector Stroke | 400 | ||||||

| 顶出力 Kn | Ejector Force | 406 | ||||||

| 顶针数 | Ejector Quantily | 33 | ||||||

| 注塑装置 | 射胶配置 | Injection Equipment | 18000I | 30000I | ||||

| 螺杆直径 mm | Screw Diameter | 130 | 140 | 150 | 150 | 160 | 170 | |

| 螺杆长径比 | Screw L/D ratio | 22.6 | 21 | 19.6 | 22.4 | 21 | 19.8 | |

| 理论射胶容积 cm3 | Shot Size | 8821 | 10231 | 11744 | 15890 | 18080 | 20410 | |

| 实际射胶量 (PS)g | Shot Weight | 8027 | 9310 | 10687 | 14619 | 16634 | 18777 | |

| oz | 286.3 | 332.0 | 381.0 | 515.9 | 586.9 | 662.6 | ||

| 射胶压力 MP | Injection Pressure | 203 | 175 | 152 | 193 | 176 | 150 | |

| 注射速率 mm/s | Injection Rate | 1034.0 | 1513.0 | 1737.0 | 1364.0 | 1533.0 | 1753.0 | |

| 射胶速度 cm3/s | Injection Speed | 98 | 77 | |||||

| 螺杆转速 g/s | Screw Speed | 10~166 | 10~100 | |||||

| 塑化能力 rpm | Plasticising Capacity | 143.0 | 152.0 | 166.0 | 160.0 | 184.0 | 205.0 | |

| 电力及其他 | 油箱容积 L | Oil Tank Capacity | 2000 | |||||

| 电热功率 Kw | Heater Power | 100 | 120 | |||||

| 电热区数 L | Team Control zone | 5+1 | ||||||

| 系统压力 MPa | System Pressure Max | 16 | ||||||

| 油泵输量 L/min | Pump Output | 1000 | ||||||

| 电机功率 Kw | Servo Power | 50+50+50+50+7.5 | ||||||

| 机器净重 ton | Machine Weight | 110 | ||||||

| 机器尺寸(长×宽×高) mm | Machine Dimension | 14500×4200×3530 | ||||||

In view of the advantages of two-platen injection molding machines

over three-platen injection molding machines, 90% of injection

molding machines over 500 tons in developed countries such as

Europe and Japan are two-platen machines. The T-two-platen

injection molding machines developed by OUCO are carefully polished

under the organization of the European Chief Technical Engineer The

products produced have absorbed the essence of Italian technology

and are manufactured in accordance with EU CE standards. They have

the characteristics of high stability, high reliability, high

precision and outstanding energy saving. The models cover 600-4000

tons.

The two-platen machine is a special model for deep-cavity products

specially developed for the market demand of large plastic parts.

The unique advantage of large part space is suitable for the

production of large-scale products: industrial plastic parts,

pallets, pallet boxes, auto parts (bumpers, air spoilers), beach

chairs and tables, etc.

The second-platen machine also has the advantages of large mold

opening stroke, fast mold change, precise control of mold clamping

force, fast injection speed, and high injection repeatability

accuracy, so as to truly meet the actual production needs of

customers.

Detailed Pictures

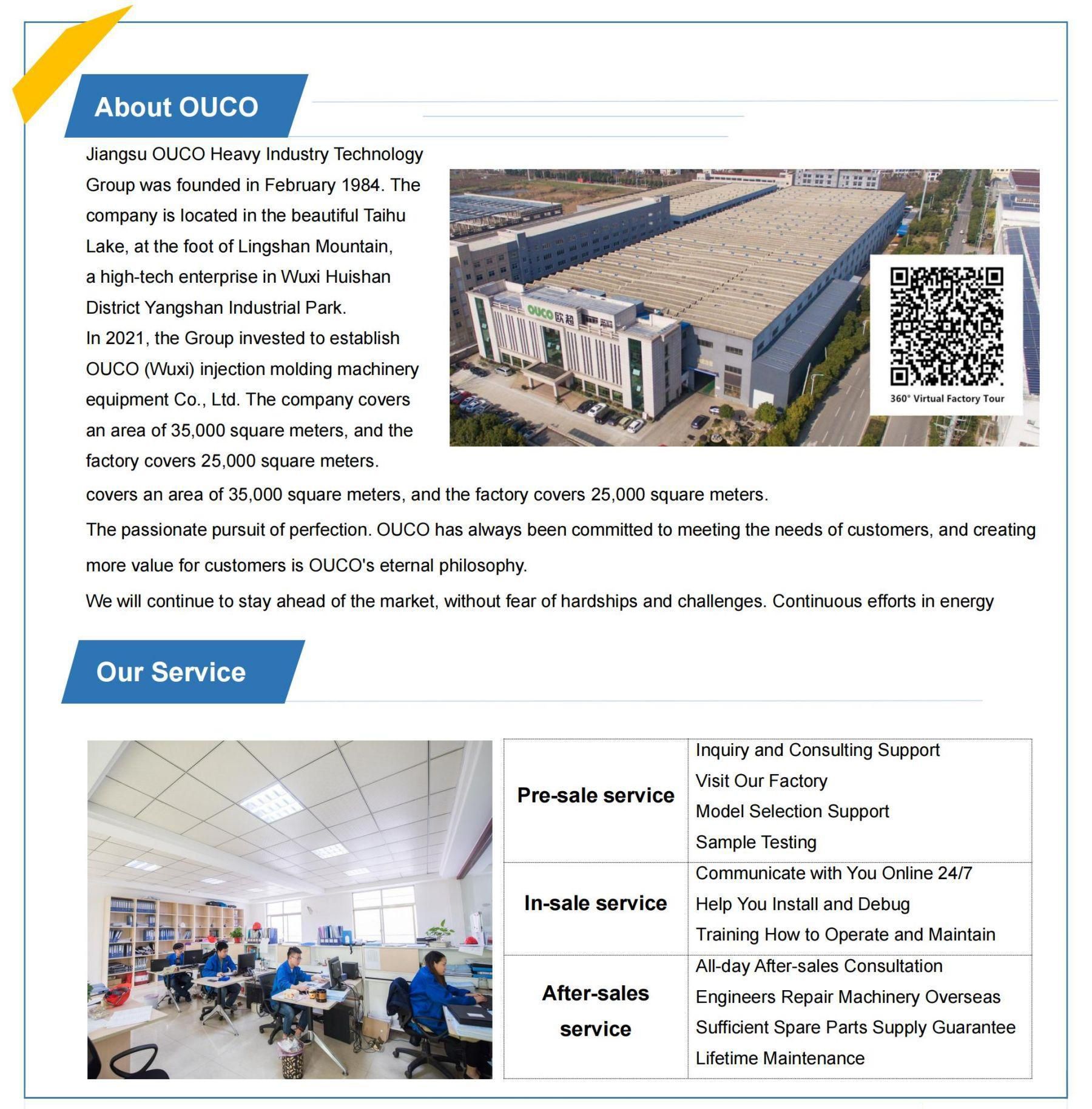

Company Profile