OUCO Energy-Saving And Environmentally Friendly Injection Molding

Machine For Manufacturing Trash Cans

The stable and practical characteristics of OUCO injection molding

machines have become the new choice for high-efficiency injection

molding, and our company can provide customers with customized

injection molding machine services, which are favored by the

industry. With the service concept of 'more professional, more

accurate, more assured', we meet the diversified needs of

customers. We keep on researching and innovating, and have been

adhering to science and technology for development and quality for

survival to develop high quality, high precision, high speed, high

energy-saving and stable injection molding machines.

Features and Advantages:

1. optimized curved elbow design, high speed mold closing system,

optimized template structure, reduce template deformation to

provide greater mold carrying capacity.

2. advanced control interface, high-speed microprocessor, direct

access to the menu, data image monitoring, self-diagnostic

capability.

3. double cylinder injection unit, more uniform screw force, screw

assembly disassembly facilitation design, no need to lower the

mold, high product repeatability.

4. Large area support template guide rail, reduce template offset,

strengthen the service life of tie rod.

Product Advantages

1.We 30 years of finishing experience with our own finishing center

equipment. After-sales service engineers, 5-20 years working

experience in injection molding machine service. Specialized in

series development, stocked with shorter delivery time.

2. Long mold opening stroke, external flip type mold closing

structure, can make bigger plastic products, the same plastic

products purchasing equipment cost is low.

3. Dual servo oil-cooled motor, sufficient power, more efficient,

can be applied to any dusty environment at the same time, good heat

dissipation, a greater extension of the life of the motor.

4. The standard configuration of the better adaptability of Taiwan

Hongxun new generation of touch-screen computer, optional Begale

and Koba computer.

Parameters

|

MODEL | OCM-800S |

| Clamping force (kN) | 800 |

| Space between tie bar (mm*mm) | 1070*970 |

| Max. mold thickness (mm) | 1200 |

| Min. mold thickness(mm) | 500 |

| Opening stroke (mm) | 2500 |

| Ejector stroke(mm) | 280 |

| Ejector force forward(Kn) | 212 |

| Screw diameter(mm) | 75 |

| Screw L/D ratio | 21 |

| Theoretical injection volume (cm3) | 1590 |

| Shot weight (PS) g | 1462 |

| Injection pressure(MPa) | 178 |

| Injection speed (mm/s) | 170 |

| Injection rate (g/s) | 750 |

| Motor power (Kw) | 107.5 |

| Oil tank capacity(L) | 900 |

| Heater power (Kw) | 30.02 |

| Machine Weight (kg) | 35 |

| Machine size L×W×H (mm) | 9400*2600*2600 |

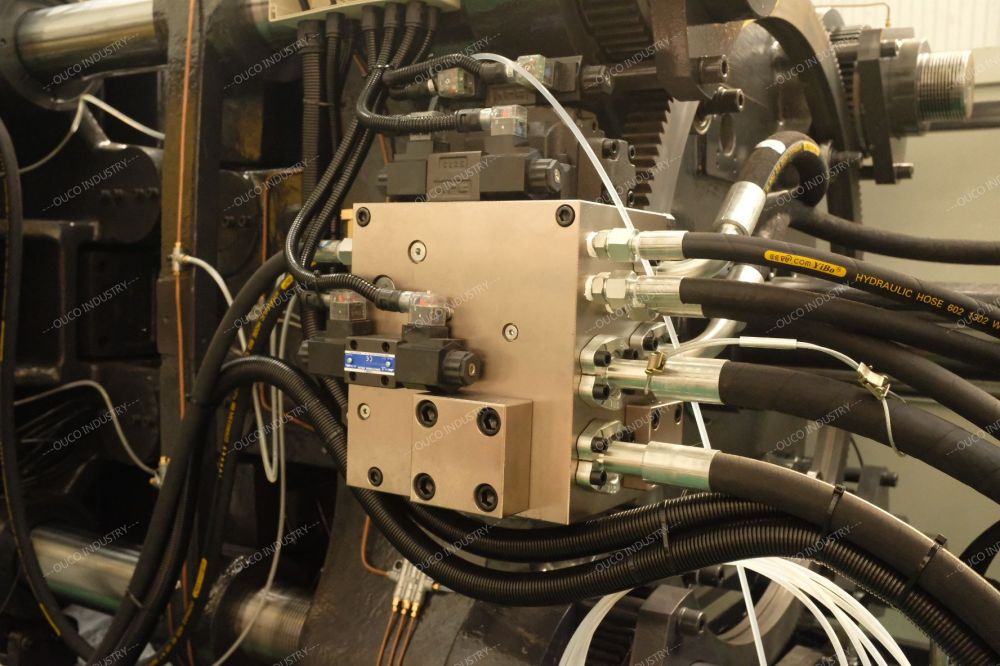

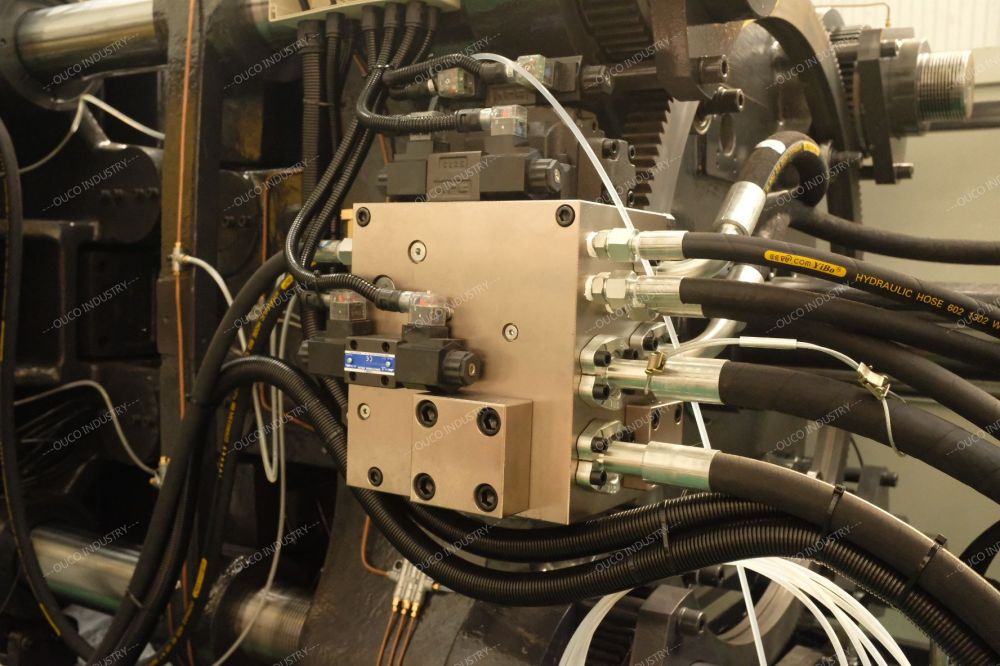

Detail Pictures

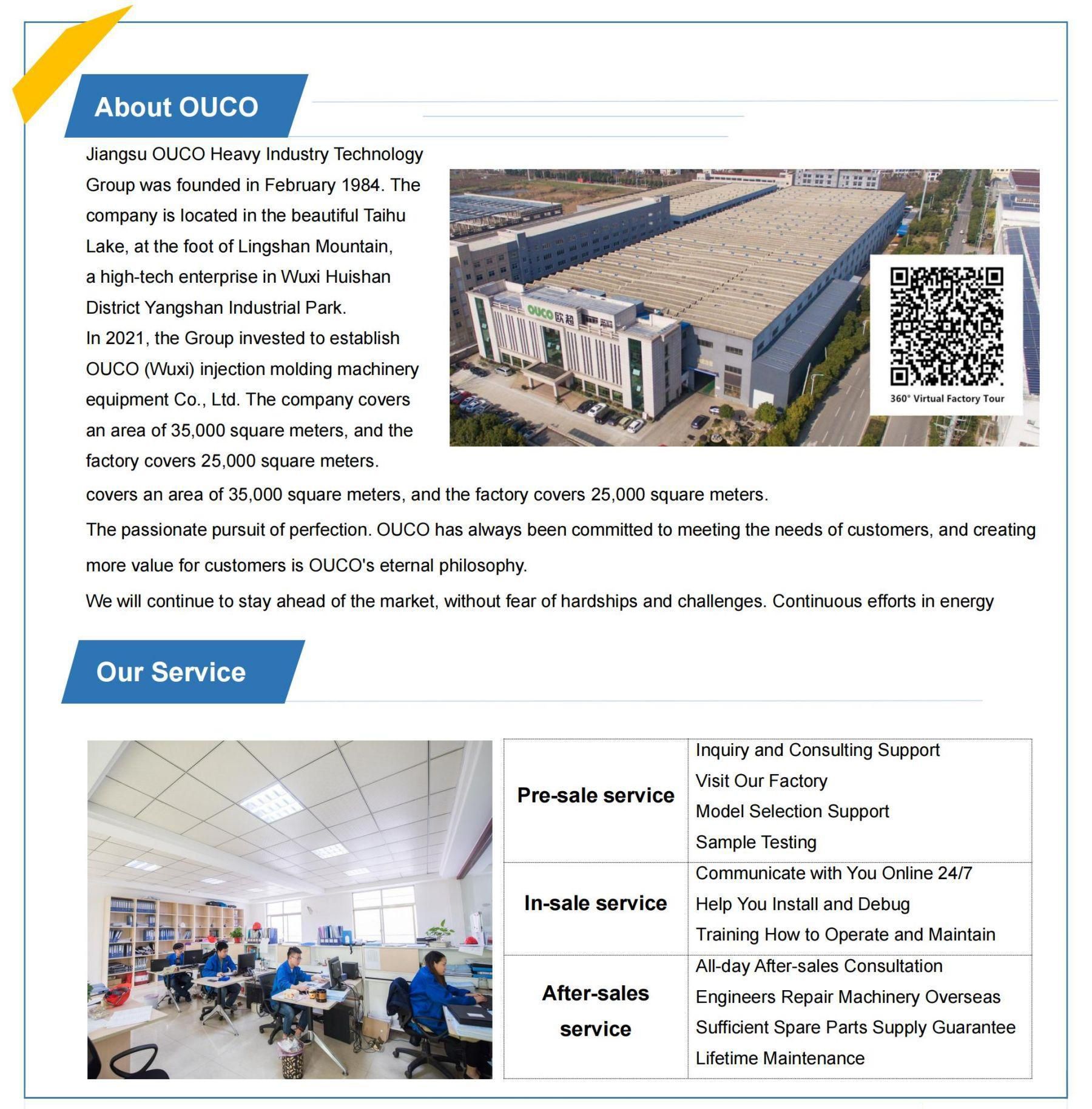

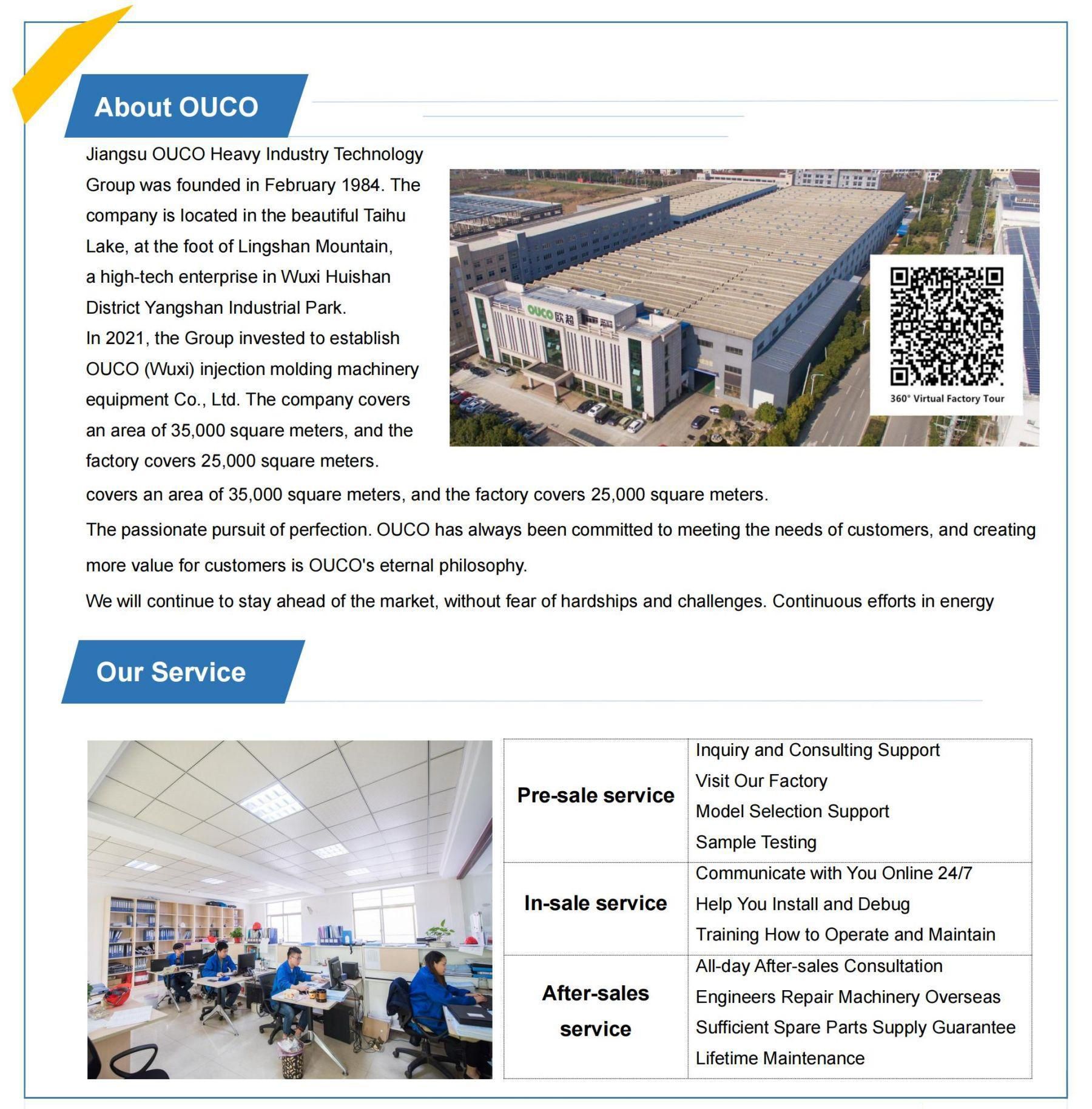

Company Profile