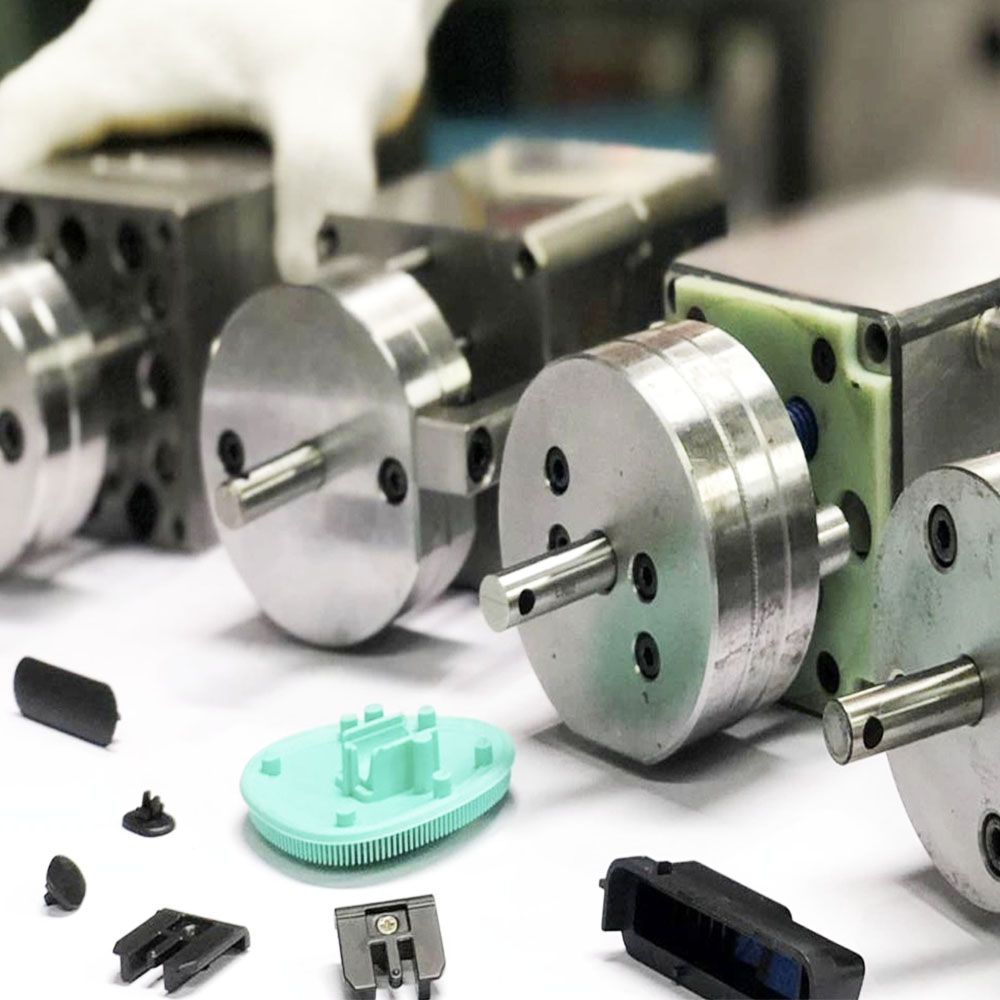

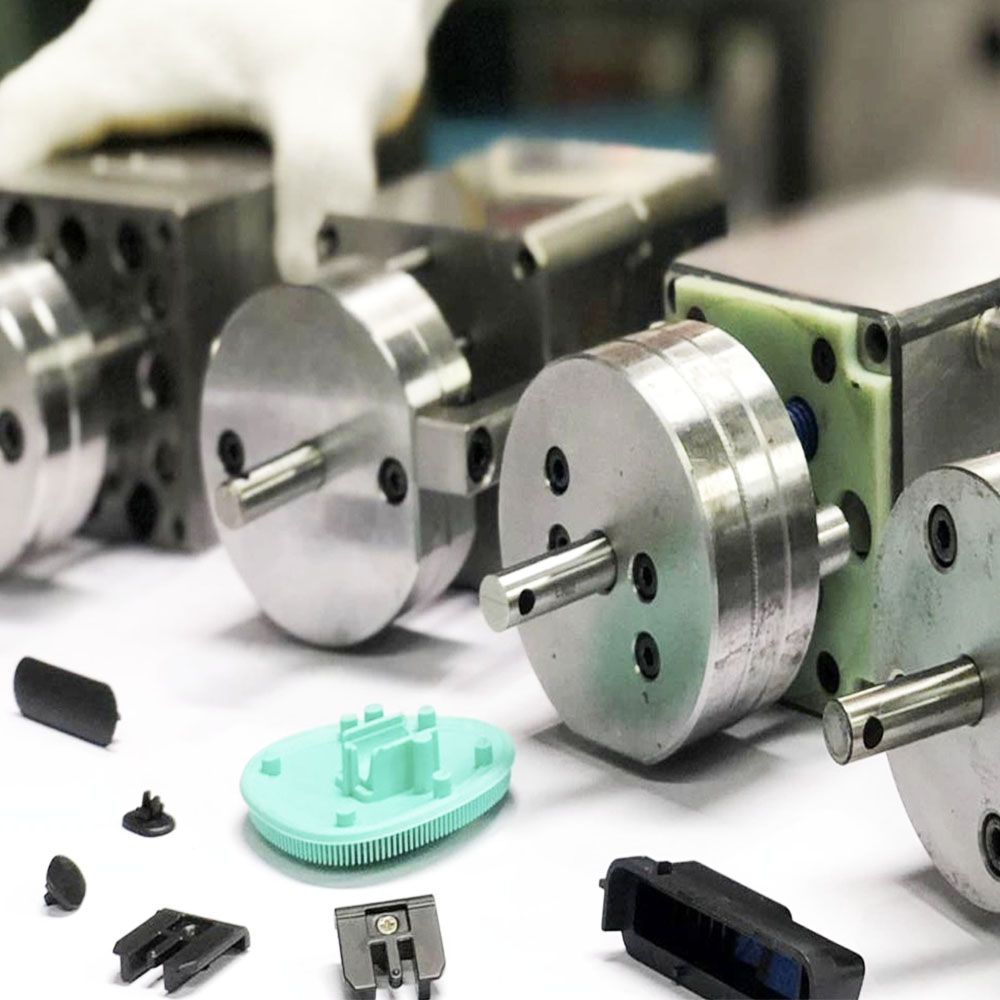

Babyplastic mould provide another solution for the samll

plastic product,which size smaller than 300mm and weight less than

10g.

Advantage on babyplastic mould for small size product:

- Low ELECTRICAL consumption. Only 3 kW of power installed, Inverter

for motor speed control. Consumption when in cycle 1.5 to 2.5 kW

- Reduced time for mould and material changes. cavity plates fixed

with two screws to centre the mould on two precise sides on the

machine platens. Material and colour change with approx. 100/150

gr.

- Low sprue/part ratio. Direct injection to the cavity plate, reduces

the sprue size. The average weight of sprue for 4 cavities: 0.6 gr.

- Low consumption to cool the mould. Mould dimensions are reduced to

just the cavity plate, thereby reducing time and energy

(cooling/heating) to achieve and maintain the correct mould

temperature.

- Production space required less than 1 m². Thanks to the compact

size (1×0.6 m), the complete production space required (machine -

chiller - power supply - cast separator - dehumidifier - robot) is

less than 1 m².

- Flexibility in high production. Production is split into multiple

machines, in case of problems, only part of the production is

stopped. Batches in different colors can be produced

simultaneously. Starting from small production you can increase it

by replicating machine/mould.

- Low investment in the mould.

- Moulds with a few cavities.

- Wide use: we made hundreds of moulds with different materials: PES,

PEI, PEEK, PSU, LCP, PBI, etc

Documents provided by Elite

- DFM report.

- Updated product drawing.

- Mould 2D/3D drawing.

- Mould timeline with many photo and process video.

- Product dimension report.

- Assembly report

- Trail video

- Moud checking list

. Delivery time:

- 2 days on mould drawing

- 2-3weeks on mould manufacture

- 3 days on mould shipment prepare.