Shanghai Zhuxin Co., Ltd. |

|

Verified Suppliers

|

|

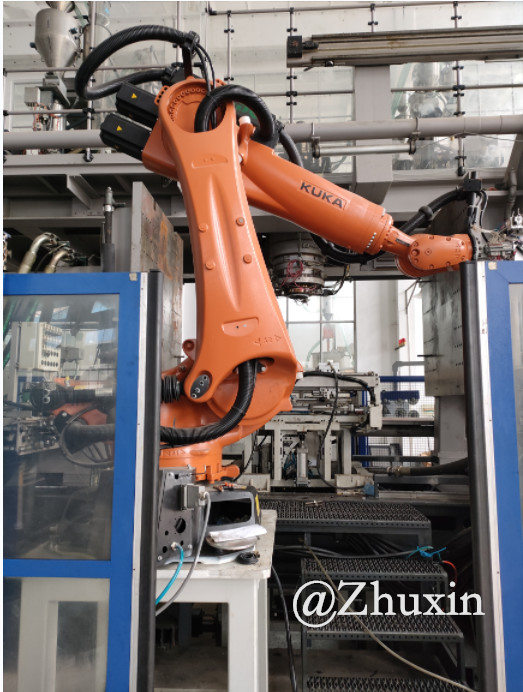

Robot Service for maintenance extending the service life and avoiding failure

The importance of robot maintenance is mainly reflected in the following aspects:

1. Extended service life: Regular robot maintenance can ensure that the various parts of the robot are properly lubricated and cleaned, reducing wear and corrosion, thereby extending the service life of the robot.

2. Improved work efficiency: The maintenance of the robot can run more smoothly, reduce failures and downtime, and thus improve work efficiency.

3. Reduce maintenance costs: Through regular maintenance, potential problems can be discovered and solved in time to avoid the accumulation of small problems into big problems, thereby reducing maintenance costs.

4. Ensure safety: The maintenance of the robot can also ensure that its safety performance is maintained to avoid safety accidents caused by failures.

5.Therefore, robot maintenance is of great significance to ensure the normal operation of robots, improve work efficiency, reduce maintenance costs and ensure safety.

| Service description of mechanical maintenance tasks | Service description of electrical maintenance tasks |

| Evaluation degree of fouling | Visual Inspection of the cabinet |

| Storage of user programs | Cleaning heat exchanger |

| Check of running noises | Cleaning cooling elements of the drive components |

| Check of joint mastering | Cleaning external fan |

| Condition check of hose packs, cable tracks and electrical installations | Battery exchange

|

| nspection of the counterbalancing system | Exchange of the cabinet sealing if needed |

| Cleaning and greasing of the base frame | Exchange of the PC – radial fan |

| Performing of necessary lubrication | Exchange of the cabinet radial fans (incl. cleaning) |

| Inspection of the drive shafts | Exchange of the mainboard battery |

| Condition and tension check of the toothed belts | Exchange of the external fan |

| Visual inspection for leaks and damages of all gear units | Creation of Back-Up image |

| Check of the Emergency Stop at the robot system | Labeling of the storage medium and handout to the customer |

| Visual inspection for leaks and damages of all gear units | |

| General visual inspection to check that connectors are undamaged and fitted securely | |

| Check of the Emergency Stop at the robot system | |

| Exchange of the cabinet filters (KR C2) | |

| Oil exchange of the wrist axis gear units (depends on the robot type) | |

| Exchange of the toothed belts (depends on the robot type) | |

| Oil exchange of main axis gear units | |

| Inspection of the motor and gear shafts axis 1 to 3 | |

Cleaning and inspection of gear rods, slide rails and roller bearings |

FAQ:

*Q:Why are we?

A:Our company works robot industry over fifteen years. Programming robot inclusive KUKA ,ABB,YASKAWA,FANUC,ESTUN(Chinese ROBOT ),EFORT(Chinese robot). the business involved simulation,programming,service after warranty period.

*Q:How about our service concept?

A:We keep on phone open all day. Stand in customer view to provide rationalization solution and robot selection.

*Q:What products can we offer?

A:robot, energy supply for robot, linear for robot. Training for robot. Gripper for handling.

*Q:Why you purchase from us?

A:You don’t worry about after-sales problem to cooperation with us.

About us

Companies in the "customer first, quality first, the user first" purpose, we will as always Warm and sincere service for all users, friends and customers, create brilliant tomorrow. Our main customers are Baosteel, INO,Volkswagen,Geely and so on. Over fifteen years experience in the robot industry. Our engineers can design solution,simulation,program and troubleshooting. So if you have any issue of robot. Call us any time. We will try our best to solve the problem. The other advantage is after-sales service,we have robot spare parts in stockroom. We can response promptly to help you resolve robot fault. We also have robot training. The course include programming, electric, mechanic and expert programming. So welcome to join our college.