AG Sonic Technology limited |

|

Verified Suppliers

|

|

100L 1500W Automatic Industry Digital Auto Parts Ultrasonic Cleaner Stain Removal

Ideal to clean rust,carbon,pait,heavy oil,fruit agricultural chemicals and other things hard to clean, without damage to parts inside tank.

Industrial ultrasonic cleaning mahine with filtration system, remove heavy oil from the surface.

Avoid re-pollution for your goods.

Liquid cycle can save cost and improve efficiency.

Structural Features: ultrasonic cleaning+ ultrasonic rinse + rinse

+ dry, continuous operation.

Control Features: ultrasonic cleaning control, heating control

temperature.

Electrical Characteristics: split electrical control cabinet,

ultrasound and rinsing can be sub-control air-dried.

Application Features: suitable for continuous cleaning; Cleaning,

rinsing and drying can be completed

Machine equipment system includes replaceable transducer box and generator. The transducer box and generator can be both build-in or separate but work together to operate ultrasonic cleaning process with transducer box immersible mounted in fluid tank, one side or both side or bottom mounted inside the tank. The number and placement of transducers is selected to give maximum results in any parts cleaning tank with any cleaning load. Specification of tank dimension and transducer boxes are custom made available. Either for mould of parts cleaning can receive perfect cleaning efficiency. Stainless steel basket is optional.

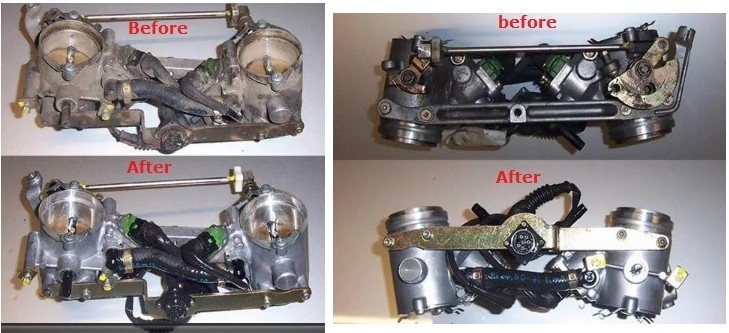

Application in Diesel Particulate Filter washing car part and metel part as below.

Automatic manufacturing semi-product and product cleaning

Automatic repair cleaning including engine,gear box,connecting rod,oil pump,crust,disc break,turbo supercharger,fuel injector,gearing,bearing and other components

Cleaning product after processing by boring and grinding machines

Ideal for car parts washing, engine block cleaning,workshop sonic bath cleaning.

Ideal to clean rust,carbon,pait,heavy oil, without damage to parts inside tank with suitable cleaning liquid.

AGsonic 3 stage unit (multi-tank) ultrasonic cleaner machine

| Industry | Cleaning objects |

| jewelry | Jewelry, diamond, gold, silver products, |

| machinery | Moulds, precision parts, pressing parts, camera parts, bearing, hardware tools |

| electronics | PCB board, electronic parts, TV parts, computer parts |

| Auto industry | engine parts, gear box, shock absorber, auto nozzle, cylinder, valve |

| Dental& Medical | dental tools, medical tools, injector, surgery tools, dropper, glass container |

| Plating& painting | polishing parts, SUS cutter, tableware, plating |

| Food industry | Oven tray, boiler, bottles, bottle cap, filters |

| Optical& watch maker | optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch band, watch cover, watch hand |

| textile | spinneret plate, rubber parts, plastic molds, toy |

| others | seal, flapper, coins, pottery, bank card, IGBT |

AGsonic make rinsing tanks and dryer tanks to dryer after rinsing, such as for tank capacity of 50L,100L,150L,200L or even bigger tank. Multi tanks with different functions by each unit work together to approach maximum cleaning efficiency.

Take 3-tank ultrasonic cleaner as example:

1st ultrasonic cleaning tank

2nd rinsing tank after rinsing(or add a second rinsing tank for thorough rinsing)

3rd dryer tank

Specification details as follows:

1st ultrasonic tank: installed with ultrasonic cleaning transducers to operate cleaning process by ultrasonic transducer vibration.

2nd Rinsing tank: It has a continues supply of water by supplying water from the bottom, and dirty liquid flow away from the surface of the liquid.

Specification details:

| Model: AGsonic | AG-1012 | AG-1018 | AG-1024 | AG-1030 | AG-1036 | AG-1072 | ||||

| TANK'S WORKING DIMENSION (mm) | L1 | 355 | 406 | 500 | 500 | 500 | 1110 | |||

| W1 | 305 | 305 | 355 | 406 | 460 | 600 | ||||

| H1 | 355 | 460 | 500 | 500 | 550 | 600 | ||||

| OVERALL DIMENSION (mm) | L2 | 535 | 586 | 680 | 710 | 710 | 1320 | |||

| W2 | 485 | 485 | 535 | 586 | 640 | 780 | ||||

| H2 | 750 | 680 | 720 | 720 | 770 | 820 | ||||

| TANK'S TOTAL CAPACITY | 38L | 56L | 88L | 101L | 126L | 369L | ||||

| TANK'S MATERIAL | SUS304 / SUS316L | |||||||||

| IN-TANK SURFACE FINISHING | Hard-Cr Plating Treatment ( 20+ microns ) | |||||||||

| HOUSING'S MATERIAL | Stainless steel | |||||||||

| ULTRASONIC FREQUENCY* | 28kHz / 40kHz | |||||||||

| ULTRASONIC TRANSDUCER | 12 | 18 | 24 | 30 | 36 | 72 | ||||

| ULTRASONIC OUTPUT POWER (MAX.) | 600W | 900W | 1200W | 1500W | 1800W |

3600W | ||||

| ELECTRONIC GENERATOR | KG600 | KG900 | KG1200 | KG1500 | KG1800 | KG3600 | ||||

| Build-in | Separate | |||||||||

| HEATER'S (HOT PLATE) POWER | 1.5kW | 3kW | 4.5kW | 9KW | ||||||

| CLEANING TANK’S POWER REQUIREMENT | AC 220V / 240V,  1, 15AMP 1, 15AMP | AC 220V / 240V,  1, 25AMP 1, 25AMP | ||||||||

| GENERATOR’S POWER REQUIREMENT | ---- | AC 220V / 240V,  1, 13AMP 1, 13AMP | ||||||||

| 68kHz / 80kHz / 120kHz are also available | ||||||||||

Features:

Adjustable ultrasonic power

Original BLT type transducer

SUS 316L stainless steel tank

Adaptable for continuous operation

Adjustable thermo controller

Adjustable ultrasonic power

With separate control ultrasonic electronic generator

sweep mode control available

digital timer & heating control

boost mode& oil skimmer upon clients requirement

pressure pump and filter system are available

Competitive Advantage:

FAQ:

Q:What are the advantages of AGsonic ultrasonic cleaner over

traditional cleaning methods?

A:1.minimize the use of manual labor

· 2.make cleaning and degreasing without the use of organic

solvents

· 3.clean hard to reach areas of products and remove all types of

dirt

·4.shorten the processes such as extraction, dispersion,

purification, chemical reactions

·5. eliminates costly mechanical and chemical cleaning of heat

exchangers

Q: What frequency is better for my parts?

A: Frequency is suggested based on pollutants in the objects.

28kHz frequency is stronger, better for car/motor/truck essel parts clean (remove oils, grease, pastes, etc. )

essel parts clean (remove oils, grease, pastes, etc. )

40kHz is better for pcb boards, electronic parts, etc.

Higher precision goods, higher frequency.

Q: Can ultrasonic cleaning damage parts?

A: Although the effect of thousands of implosions per second is

very powerful, the cleaning process is safe. No damage to your

daily objects.

Q: What cleaning solution should I use?

A:A large variety of different formulas designed for specific

applications. Proper selection is crucial for acceptable cleaning

activity and to prevent unwanted reactions with the workpiece.