HENAN DIANYAN NEW ENERGY TECHNOLOGY CO., LTD. |

|

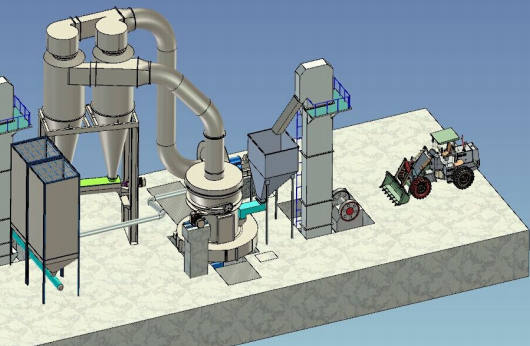

60-325mesh gypsum Grinding Mill Machine limestone Grinding Machine ,marble grinder,zinc ore grinder

Working Method

The material enters the grinding chamber via the funnel and spiral conveyor where it is sheared and broken by the fastrotating blades. The power passes the guide ring and enters the classification chamber. As the classification wheel is in revolution, both the air force and centrifugal force act on the powder.

As the particles whose diameters are greater than the critical diameter (diameter of the classification particles) have a great mass, they are thrown back into the grinding chamber to be ground again, while the particles whose diameters are smaller than the critical diameter enter the cyclone separator and bagtype collector via the material exit pipe be means of negative pressure wind conveyance.The discharge material meets the requirement for the product.

Working Principle

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of MTM Medium-speed Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure. Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.

| ||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1 Are you a trade company or factory ?

Dianyan owns 12000 square meters of standardized heavy industrial factory, with more than 30 sets of large and medium sized metal processing, riveting welding and assembly equipment, registered capital of 10 million yuan, more than 100 employees and 30 engineering technicians.

2 How can I trust your company?

Dianyan has passed gained many certification, such as ISO 9001: 2008 and SGS. Our company import advanced technology from the United States, Germany, Japan, Australia. Its main parts and wearing parts are made of wear-resistant materials and advanced processing technology to keep the equipment durable and long lifetime, main products such as metal shredder, boiler desulfurizing tower, dust collector, rubber tire crushing and grinding plant, metal crusher are exported to Southeast Asia, Russia, and Kazakhstan, and Turkey, and South Africa, and Egypt, and Vietnam, and India, and Australia, North Korea, Canada and the European Union and other countries and regions.

3 What Will We Do If We Have Problems in Machine Working After We Buy the Machine?

Dianyan has after-sale service people and you can feel free to send us the picture or video to show us your problems ,we will give you solutions in 24hours.

4 Where are you? Can we go to China and visit your factory?

Yes, of course. We are in Zhengzhou , China. Welcome to our factory.

5 Is your price competitive?

Surely we can give you best factory price based on superior product and service.

6 Any warranty?

Under the proper usage, one year to 18 months for whole machine.

7 How to pay to you ?

we accept the payment by T/T , Western Union , Cash, L/C, D/P and Money Gram .

8 How long is the delivery time?

For standard machines, it would be 5-7 days; For non-standard machines and customized machines according to clients specific requirements, it would be 30 days.We will arrange the production and shipment as soon as possible when we received the deposit, and update the information with the customer on line.