Shenzhen Canroon Electrical Appliances Co., Ltd. |

|

Verified Suppliers

|

|

Induction heating machine 40KW for cast iron melting electric magnetic power supply

CR1300 series is mainly used in all kinds of plastic machinery (such as: injection molding machine, extruder, pelletizer,

film blowing machine, wire drawing machine energy-saving transformation), chemical fiber equipment, food and medicine

machinery, steam and hot air preparation and other industries.

Quick Detail Induction heating machine 40KW for cast iron melting electric magnetic power supply

Place of Origin:China (Mainland)

Brand Name:Canroon

Model Number:CR1300-010A

Power : 10kw

Voltage : 3-phase 380-460V

startup time :< 0.2S

Electro-thermal conversion : > 95%

Effective power :> 85%

Usage : Industrial Heat System

Storage temperature :-30℃~+60℃

Overload protection :120% per minute 150% instant protection

Certification:CE ISO9001:2015

Main functions of Induction heating machine 40KW for cast iron melting electric magnetic power supply

1.Start mode is optional

Remote boot (external terminal boot and 24V pulse boot), keyboard

boot.

2.Perfect protection function

Overheat, overvoltage, undervoltage, lack of phase, overcurrent

(including hardware overcurrent protection,

software overcurrent protection, VCE protection) and other protection, and temperature sensor fault detection function

3.Load inductance detection function

Can measure the size of the load inductance, when the inductance is

too large or too small, alarm and start the

corresponding protection function.

4.Various heating modes

Maximum power heating, curve heating, twenty section heating,

analog amount (0 ~ 10V /4 ~ 20mA) control

heating and other heating modes

5.Run limited function

The limited run time can be set as required.

6.Parameter storage function

Instant storage of fault information; Power consumption,

accumulated running time and so on are stored every 2 hours.

7.External fault signal input and local fault signal output.

Curve heating mode:

Set the heating mode (F008) as 1, that is, set the curve heating

mode. The initial power (F023) and heating time (F022)

of the curve can be set to make it heat according to the predetermined curve.

Curve heating mode can set the curve heating time and starting power. Curve heating time is the time from starting power to

the maximum power. The power increases with the slope as a multiple of the maximum power/starting power. When the

maximum power is reached, the heat is heated at the maximum power. The curve heating model is shown in the figure below:

4 ~ 20mA control mode:

Set the heating mode (F008) as 4, that is, set the mode of 4 ~

20mA. At this time, the output power can be adjusted

by the input current value of the analog quantity.

0 ~ 10V control mode:

Set the heating mode (F008) as 3, that is, set the control mode of

0 ~ 10V. At this time, the output power can be

adjusted by the input voltage value of the analog quantity.

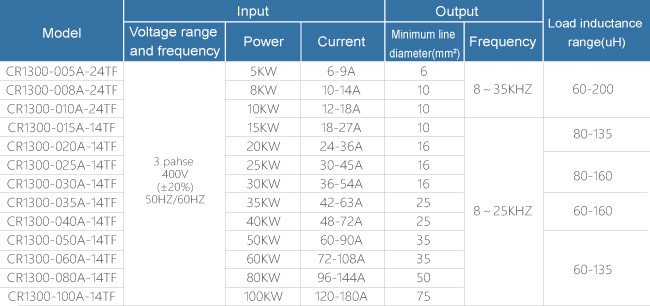

Technical parameters of Induction heating machine 40KW for cast iron melting electric magnetic power supply

Application details of Induction heating machine 40KW for cast iron melting electric

magnetic power supply

Company information:

Our Services

1. keep the quality first and make more products benefit to our customers' need

2.about our Online/Sale service

super and solid quality,Fast and punctual delivery,Standard export package or as customers’ need.

3.After-sale service

Assistance to your project,Repairing and maintenance if any problem occur in the warranty, Installation and

clerks training,Spare and wearing parts for free or with big discount,Any feedback of machines can be told to

us, and we will try our best to support you.

FAQ:

1. Are you a trading company or manufacturer?

We are manufacturer located in Shenzhen, China, specialized in induction heating power for many years.

2. What's the delivery time for sample and bulk order?

Normally we have stock of the mini and medium items, 1-3 days for sample order, 15-40days for 20 GP and 40HQ quantity.

3. What's your quality guarantee period?

12 months warranty

4. Can I get a lower price if I order large quantities?

Of course. Cheaper price with larger quantity

5. can you customize the machine for us?

Yes, of course, just tell me your detailed requirement, so I can suggest you most suitable project.