Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

1. Main Features of high frequency induction brazing machine:

1.Leading technology

Digital intelligent power supply adopts DSP processor control and

digital control technology. The control process, data operation and

parameter storage of the system are all processed in digital

form.Environmental changes such as temperature changes do not

affect the internal processes and results of the system

2.Touch screen display

The working state and working parameters of the machine can be

displayed directly on the touch screen. The display parameters

include: working frequency, oscillating current, dc voltage, dc

current, output power and other parameters.Working status includes

functions such as load matching instructions

3.The signal transmission adopts optical fiber transmission

The electromagnetic environment inside the power cabinet is

complex, and the transmission of weak current signals (such as

drive signal, protection signal, feedback signal, etc.) is

vulnerable to electromagnetic interference, while the light is not

affected by the electromagnetic environment, so these important

signals adopt optical fiber transmission to improve the overall

stability and reliability of the equipment.

4.Intelligent protection function:

Condition of power supply in normal work, if suddenly will

automatically latch fault alarm, at this time, all kinds of

protection and fault alarm signal, such as: light capacitor, power

cabinet to open the door, IGBT power speed protection, diode

special protection, over voltage, over current, lack of phase,

water flow, water temperature and other protection, to ensure that

the equipment is reliable and durable

5.Fault self-diagnosis and online processing

When the alarm occurs due to wrong operation or special working

condition, the touch screen will display the fault content, and the

solution to the corresponding fault can be found by clicking the

help of corresponding fault.More than 90% of common faults can be

quickly handled by operators, which greatly improves production

efficiency and reduces the reliance on operators' technical level

6.Constant power output mode

Output power does not change with workpiece temperature, high

production efficiency and good product quality

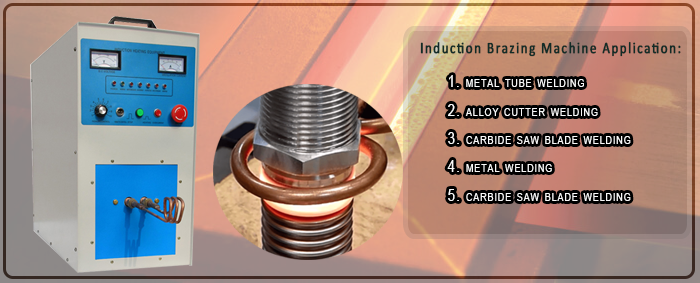

2. Induction Brazing Machine working principle :

Based on the principle of electromagnetic induction,our machine

could make induced current generate inside the metal material,which

is in the alternating magnetic field.Then this current could heat

the material up to the melting state.

Our induction brazing machine model is suitable to used for the

brazing of circular saw and other tools, usually 4 to 9 seconds is

needed to braze one diamond blade.

3. Technical Parameters of LSW-30 Induction Brazing Machine:

| Model | LSW-30 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 30kw |

| Oscillation frequency | 25-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 25L/Min,0.15-0.2MPa |

| Weight | 48kg |

| Dimension (L*W*H ) | 690*290*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

4. Advantage of high frequency induction brazing machine:

A. Fast Heating: the quickest heating speed is less than 1 second,

and the heating speed adjusting and control are available.

B. Widely Applicable: it can be used to heat various metal parts.

C. Low Power Consumption: compared with traditional heating method,

the heat efficiency can be over 95%.

D. High Effectiveness: fast warming and uniform heating, reduce the

workpiece oxidation and deformation.

E. High Efficiency: can do 24 hours continuously working with

comprehensive full load design.

F. Small Footprint & Light Weight:save space of workshop and

easily moved.

G. Easy Operation: easy installation and operation, which can learn

in only several minutes. It can be started to peform on condition

that water and power supply are available.

H. Environmental Friendly: free of noisy, exhaust gas and dust, so

can provide a better working surroundings