Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

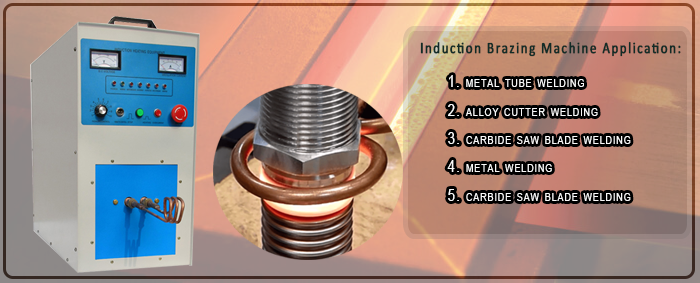

30kw copper tube high frequency induction heating brazing welding machine

1. High Frequency Induction Brazing Machine Application :

It mainly melts the solder by heating to a certain temperature, so

as to connect two metals of the same material or different

materials together. The specific applications are as follows:

1. Welding of various hardware tools: welding of diamond tools,

abrasive tools, drilling tools, alloy saw blades, carbide turning

tools, milling tools, reamers, planers, woodworking bits, etc.

2. Welding of various hardware and machinery accessories: hardware

bathroom products, refrigeration copper accessories, lighting

accessories, precision mold accessories, hardware handles, egg

beaters, alloy steel and steel, steel and copper, copper and copper

and other metals of the same or dissimilar metals silver welding

and brazing.

3. Composite pot bottom welding is mainly used for three-layer

brazing of round, square and other special-shaped flat stainless

steel pot bottoms and aluminum sheets, and can also be used for

other metal plane brazing.

4. The heating plate welding of electric kettle (electric coffee

pot) is mainly used for brazing between stainless steel flat

bottom, aluminum sheet and electric heating tubes of various

shapes.

5. Welding of mining tools, such as "one" bit, column tooth bit,

dovetail briquette bit, riveting rod bit, welding of various

shearer picks and various roadheader picks.

6. Welding of various woodworking tools, such as welding of various

woodworking planers, milling cutters and various woodworking

drills.

7. Small hardware welding, copper welding, towel rack, soap net,

bath towel rack, auto parts, motorcycle accessories, metal

terminals, small hardware, electric heating pipe fittings and

fasteners, etc.

2. Technical Parameters of LSW-30 Induction Brazing Machine:

| Model | LSW-30 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 30kw |

| Oscillation frequency | 25-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 25L/Min,0.15-0.2MPa |

| Weight | 48kg |

| Dimension (L*W*H ) | 690*290*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

3. Main characteristics of LSW-30 Induction Brazing Machine :

1) IGBT inversion technology based LC series circuit .

2) Phase locking looping technology and soft switch ensure good

reliability and realize power and frequency tracking automatically.

3) Diode rectifier cause high power factor more than 0.95

4) Power can be instantly turned on or shut off with working in

100% load

5) Perfect protective circuit and cooling system designed.

6) Low energy consumption: converts up to 97.5% above of the

expended energy into useful heat. Energy saving 15%-30% compared

with SCR induction heating machine.

7) Safety Operating and easy installation.

4. Precautions for the use of high frequency welding equipment:

1. The computer room should be well ventilated and kept clean, tidy

and dry. The equipment must have more than two people to start the

operation, and designate the person in charge of the operation.

Operators should be familiar with and abide by the operating

procedures of the quenching equipment, and wear the prescribed

protective equipment. The workpiece should be removed from burrs,

iron filings and grease, otherwise it is easy to cause arcing, and

the workpiece should also be prevented from contacting the sensor

to cause arcing during operation. When using high-frequency

quenching machine tools, attention should be paid to the safe

operation rules of electrical, mechanical and hydraulic

transmission. The equipment needs to be repaired by a special

person. Before repairing, discharge the capacitors with a discharge

rod. It is strictly forbidden to carry out emergency repairs with

electricity.

2. High-frequency induction heating equipment uses industrial

electric frequency, low voltage and high current to heat and quench

or normalize large workpieces. When using it, the rules for safe

electricity use should be observed.

3. In order to prevent the large workpiece from bursting and

hurting people during high induction heating, the operation rules

of high frequency heat treatment and the corresponding heat

treatment process rules for large workpieces must be strictly

followed. Ultrasonic flaw detection should be carried out on large

workpieces one by one. For workpieces with defects such as white

spots, serious segregation and looseness, it is forbidden to use

high-frequency equipment to heat them. The workpiece should be free

of burrs, iron filings and oil to prevent arcing. In the production

operation, the person in charge must be designated, and the

operator must be familiar with and abide by the operating

procedures of the high-frequency induction heating equipment.