Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

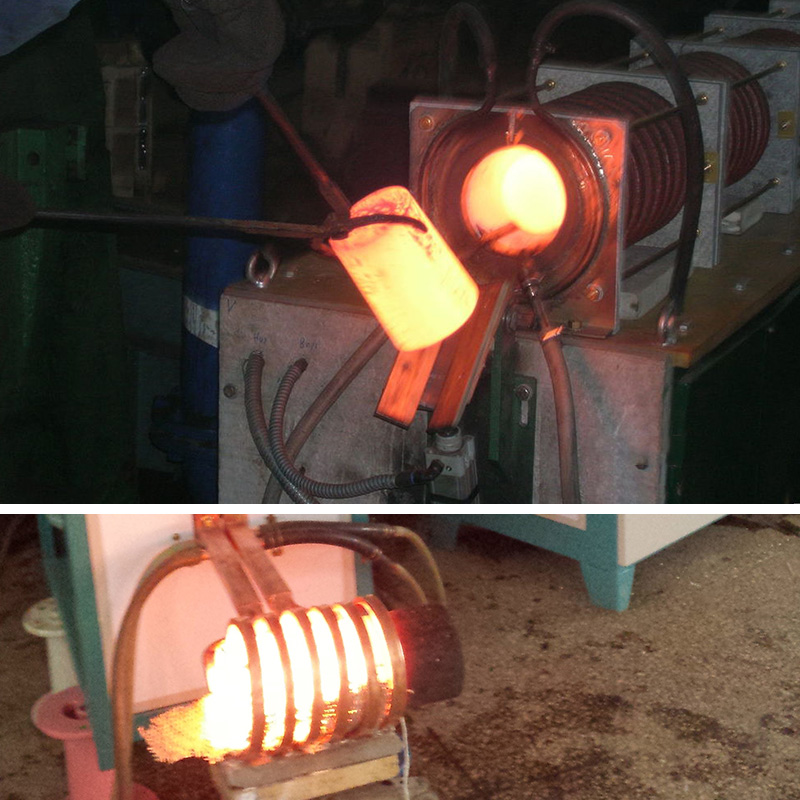

1. Application range(forging furnace induction heating machine):

1) Hot forming/forging of the standard components and fasteners

2) Hot forging of the automobile and motorcycle parts, metallic

tools

3) Hot forging of embryo gear parts

4) Heat distortion of pipes

5) Other forging applications.

6) Suitable for workpiece with various shape and different diameter

7) Customized forging production solution

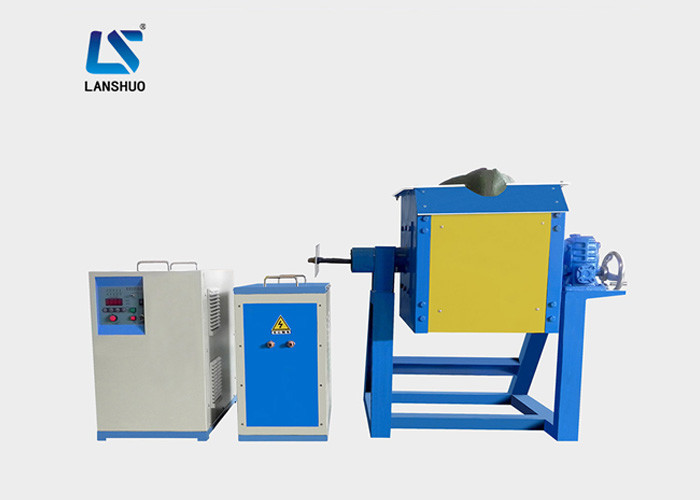

2. Technical Parameters of LSW-200 IGBT induction heating machine:

| Model | LSW-200 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 200kw |

| Oscillation frequency | 10-20KHZ |

| Duty cycle | 100% |

| Cooling water flow | 50L/Min,0.2MPa |

| Weight | 380kg |

| Dimension (L*W*H ) | 1070*640*1870mm / 870*530*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating,quenching etc |

3. Features of IGBT induction heating equipment: suitable for heating steel bars, pipes, plates and angle steels.

1. Be applicable to heating, quenching / hardening, etc.

2. IGBT technology as the core.

3. Environmentally friendly: no air pollution, no dust and little

noise.

4. Reduced operating cost: high automation, fewer operators needed.

5. Energy saving: high energy conversion.

6. High efficiency: Metal can be heated to its desired temperature,

even its melting point, instantly.

7. Duty cycle 100%: can work for 24 hours without a stop.

4. Our Service:

Pre-sale service:

1) Recommend the most suitable machine for customers, according to

their requirements.

2) Inquiry and consulting support.

3) Sample testing support.

4) Visit our factory.

In-sale service:

1) Update the production process timely for you.

2) Carry out test according to relevant equipment test run

regulations.

3) Strictly check up the machine before delivery.

4) Deliver on time.

After-sale service:

1) one year warranty period.

2) At warranty period,the replacement of quality-problem parts is

realized.

3) If any big quality problems occur out of the guarantee period,

we will send maintenance.

4) We will provide a lifetime favorable price to the buyer with the

materials and spare parts used in system operation, equipment

maintenance.

5. Related Products:

| KGPS Melting Furnace | LSZ Melting Furnace | Cooling Tower |

|  |  |