Step 1 - Survey Property Lines

Be sure that the fence does not exceed property lines. Most fence

installers recommend that all posts be set approximately 4" inside

the property line. This will help avoid encroaching on adjoining

property with concrete footings. This is easily done by stretching

a string along the property line and setting the posts 4" inside.

Step 2 - Locate and set Terminal Posts (corner, end, and gate posts

are called terminal posts)

Distance between gate posts is determined by adding the actual

width of the gate plus an allowance for hinges and latches. Usually

walk gates require 3 3/4" for hinges and latches and double drive

gates require 5 1/2". Next, dig the holes.

Terminal posts should be set 2" higher than the height of the fence

fabric and line posts 2" lower than the height of the fence fabric

(terminal posts should be 4" higher than the line posts). Set the

terminal posts in concrete using a concrete mix. You can use 1 part

cement, 2 parts sand, and 4 parts gravel. There is also pre-mix

cement. Use a level to make sure the posts are straight. Posts

should be centered in the hole. Crown posts footings so the water

will drain away from the posts.

Step 3 - Locate and set Line Posts

After the concrete around the terminal posts have hardened, stretch

a string tight between the terminal posts. The string should be 4"

below the top of the terminal posts. Line posts should not be

spaced more than 10 feet apart. For example, if the length between

two terminal posts is 30 feet, then line posts would be spaced 10

feet apart (see chart below).

Line Post Spacing Chart Space Between Terminal Posts | Set Line Posts Apart | | Space Between Terminal Posts | Set Line Posts Apart | 30 ft | 10 ft | 76 ft | 9 ft 6 in | 31 ft | 7 ft 9 in | 77 ft | 9 ft 7 in | 32 ft | 8 ft | 78 ft | 9 ft 9 in | 33 ft | 8 ft 3 in | 79 ft | 9 ft 10 in | 34 ft | 8 ft 6 in | 80 ft | 10 ft | 35 ft | 8 ft 9 in | 81 ft | 9 ft | 36 ft | 9 ft | 82 ft | 9 ft 1 in | 37 ft | 9 ft 3 in | 83 ft | 9 ft 3 in | 38 ft | 9 ft 6 in | 84 ft | 9 ft 4 in | 39 ft | 9 ft 9 in | 85 ft | 9 ft 6 in | 40 ft | 10 ft | 86 ft | 9 ft 7 in | 41 ft | 8 ft 2 in | 87 ft | 9 ft 8 in | 42 ft | 8 ft 5 in | 88 ft | 9 ft 9 in | 43 ft | 8 ft 6 in | 89 ft | 9 ft 10 in | 44 ft | 8 ft 9 in | 90 ft | 9 ft | 45 ft | 9 ft | 91 ft | 9 ft 2 in | 46 ft | 9 ft 2 in | 92 ft | 9 ft 2 in | 47 ft | 9 ft 5 in | 93 ft | 9 ft 3 in | 48 ft | 9 ft 7 in | 94 ft | 9 ft 5 in | 49 ft | 9 ft 9 in | 95 ft | 9 ft 6 in | 50 ft | 10 ft | 96 ft | 9 ft 7 in | 51 ft | 8 ft 6 in | 97 ft | 9 ft 7 in | 52 ft | 8 ft 8 in | 98 ft | 9 ft 8 in | 53 ft | 8 ft 10 in | 99 ft | 9 ft 9 in | 54 ft | 9 ft | 100 ft | 10 ft | 55 ft | 8 ft 2 in | 101 ft | 9 ft 2 in | 56 ft | 9 ft 4 in | 102 ft | 9 ft 3 in | 57 ft | 9 ft 6 in | 103 ft | 9 ft 4 in | 58 ft | 9 ft 8 in | 104 ft | 9 ft 5 in | 59 ft | 9 ft 10 in | 105 ft | 9 ft 6 in | 60 ft | 10 ft | 106 ft | 9 ft 7 in | 61 ft | 8 ft 8 in | 107 ft | 9 ft 8 in | 62 ft | 8 ft 10 in | 108 ft | 9 ft 9 in | 63 ft | 9 ft | 109 ft | 9 ft 10 in | 64 ft | 9 ft | 110 ft | 10 ft | 65 ft | 9 ft 3 in | 111 ft | 9 ft 3 in | 66 ft | 9 ft 5 in | 112 ft | 9 ft 4 in | 67 ft | 9 ft 7 in | 113 ft | 9 ft 5 in | 68 ft | 9 ft 8 in | 114 ft | 9 ft 6 in | 69 ft | 9 ft 10 in | 115 ft | 9 ft 7 in | 70 ft | 10 ft | 116 ft | 9 ft 8 in | 71 ft | 8 ft 9 in | 117 ft | 9 ft 9 in | 72 ft | 9 ft | 118 ft | 9 ft 10 in | 73 ft | 9 ft 2 in | 119 ft | 9 ft 10 in | 74 ft | 9 ft 3 in | 120 ft | 10 ft | 75 ft | 9 ft 4 in | 121 ft | 9 ft 3 in |

Dig the post holes and set the line posts. Before concrete begins

to set, adjust post height by moving post up or down. Top of the

line posts should be even with the string. Check with level to make

sure posts are straight.

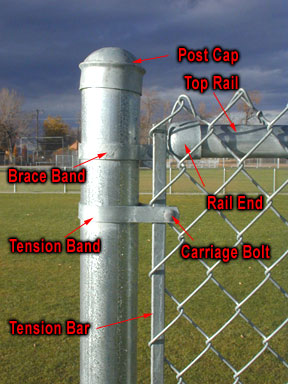

Step 4 - Apply Fittings to Terminal Posts

Check material list and fittings chart above. After all posts have

been installed and the concrete footings have hardened, slip the

tension and brace bands onto the terminal posts. The long flat

surface of the tension band should face towards the outside of the

fence. Take care not to spread or distort the fittings. Now apply

terminal post caps.

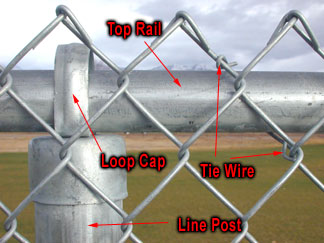

Step 5 - Apply Top Rail

Attach loop caps to line posts. Insert one length of top rail pipe

through the eye-top closest to one of the terminal post. Slide a

rail end onto the end of the top rail and attach it to a termianl

post by using the brace band (If using swedge top rail, do not

insert the swedged end into the rail end). Secure the rail end to

the brace band with a carriage bolt. Continue by attaching top

rails together. If swedged top rail is not used, you'll connect the

rail ends together by using top rail sleeve. Upon reaching the

other terminal post, measure carefully and cut the top rail to fit

tightly into the rail end. Secure rail end to the terminal post

with brace band and carriage bolt.

Step 6 - Hang Chain Link Fabric

Unroll the chain link fabric on the ground along the fence line.

Slide tension bar through the last link on the chain link fabric.

Stand the fabric up and lay it against the posts. Fasten the

tension bar (that you just inserted) to the terminal post with

tension bands (already on the post). Use the carriage bolts with

the head to the outside of the fence. Walk along the fence and take

the slack out. Loosely attach fabric to top rail with a few wire

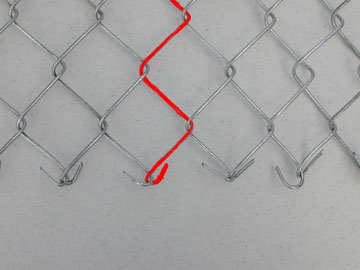

ties. To connect two sections or rolls of fence fabric together - take a

single strand of wire from one of the sections of fence (Sometimes

it is necessary to remove a second wire on the one end in order for

the two sections to mesh properly.). Place the two section of fence

next to each other (end on end). Join the two sections by winding

(corkscrew fashion) the loose strand down through the fence. Join

and tighten the knuckles at bottom and top. Now you shouldn't even

be able to see where the two sections were connection together. To remove excess chain link fence fabric - untie both top and

bottom ends of fence (knuckles - pliers shown below). Twist the

wire in a corkscrew fashion until the fence comes apart. One picket

shown in red is turned until the fence is separated.

|