Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

HWASHI Best Price Three-phase Standing Roof Seam Welding Machine Seam Welder,tpo roofing welder

Product Introduction:

Standing Roof Seam Welding Machine can be apply to stainless steel

and titanium based material. The excellent corrosion resistance

performance suit for harsh environments long service life and

environmental pollution. The automatic roof welding system simplify

the process for seams connections. The entire roof will be covered

by the seamless metal roofing. Less concern on water penetration

and air leakage. Extreme performance under strong wind and uplift

resistance.

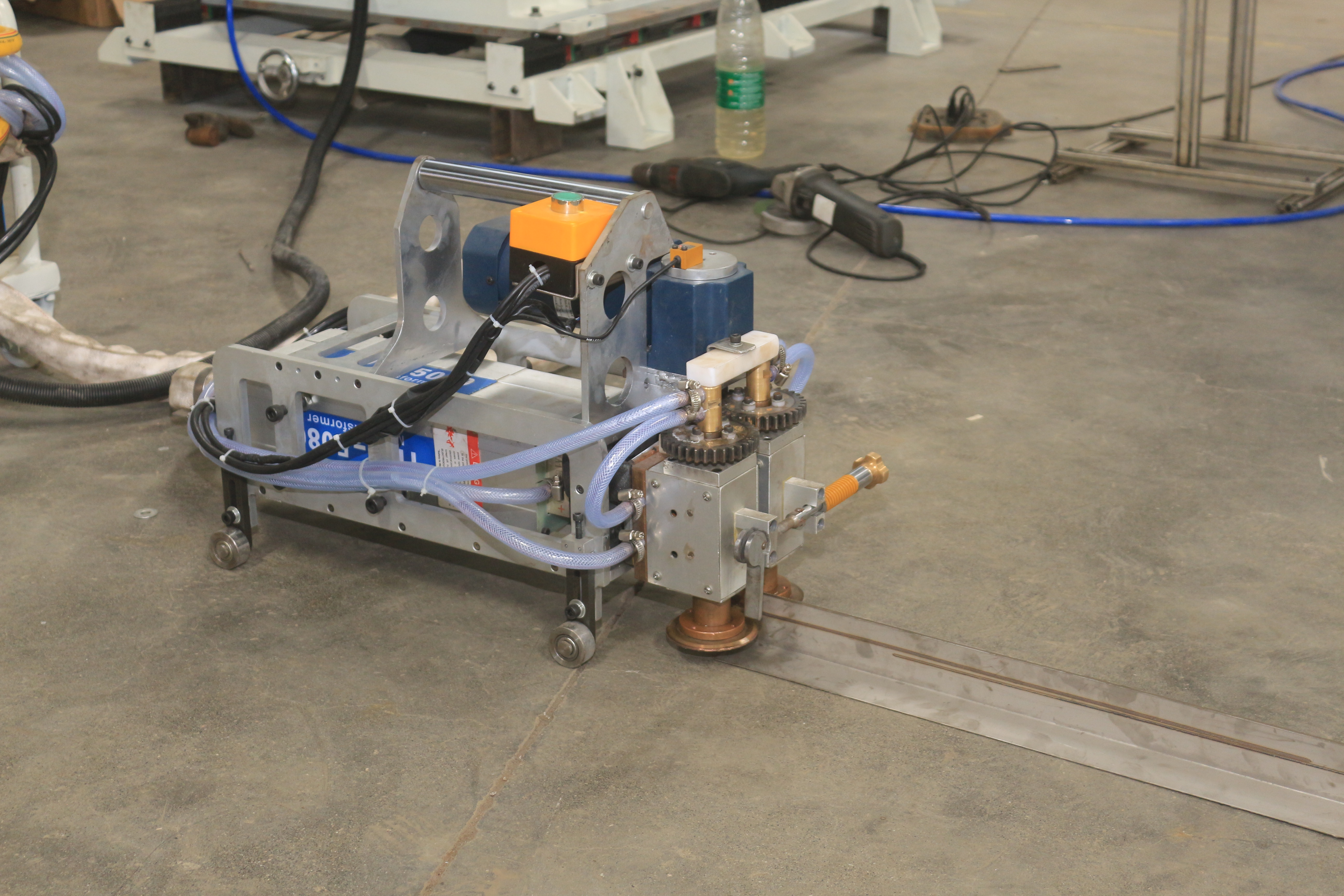

This seam welding equipment is special for stainless steel roof

welding.Transformer, controller, welding mechanism and cooling

mechanism are put on the four-wheel trolley, which can be pushed to

move freely manually. When welding, the motor drives the roller

wheel to drive the trolley to move and weld in a straight line.

Welding pressure uses spring pressure, no pneumatic component

structure; Welding mode can be switched to two welding modes: seam

welding or spot welding in the welding system. The design selects

the MF inverter dc welding system as the welding source. The

transformer is small in size, the equipment is lighter in weight,

and it is easy to move. One person can independently complete the

operation and use of the equipment.

In order to meet the needs of welding, the equipment can meet the welding conversion of two and three layers of materials, the thickness of which is 0.6+0.5+0.6mm.

working process

Manually push the equipment to the welding position - raise the

wheels of the car - adjust the rolling pressure according to the

spring force conditions - start welding - the car automatically

move welding - welding complete - release the spring boost - move

to the next welding position - the equipment cycle production

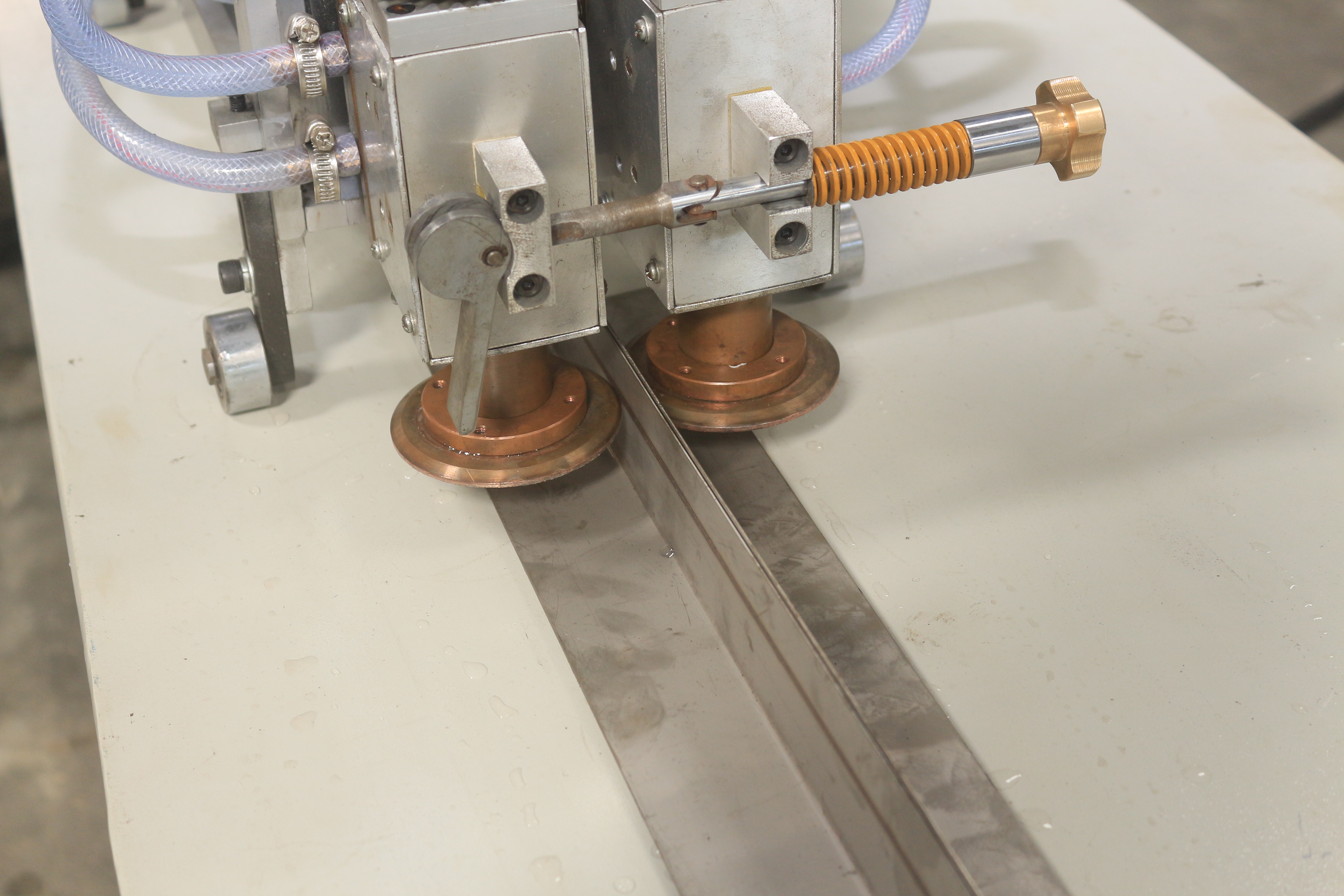

Welding Method of The Seam Welding Machine

Adopt standardized welding electrode. Special electrode molds and welding methods can also be customized according to the product specification.

Features of The Seam Welding Machine

Flexibility: Customizable to meet specific customer requirements, it can accommodate different sizes and shapes of wheel rim strips.

Strong Stability: High equipment stability enables long-term stable operation, reducing failures and downtime during production.

Reliability: Manufactured with high-quality materials and components, it has a long service life and high reliability, reducing maintenance costs and downtime.

Energy Efficiency and Environmental Protection: Energy-saving power systems and environmentally friendly materials are used in the design and manufacturing process, meeting the requirements of sustainable development in modern industry.

Specification

| Model | WL-FS-75K | WL-FS-100 | WL-FS-125 | WL-FS-160 | WL-FS-200 | WL-FS-250 |

| Rated Capacity KVA | 75 | 100 | 125 | 160 | 200 | 250 |

| Voltage V | 380*2 | 380*2 | 380*2 | 380*2 | 380*2 | 380*2 |

| Duty Cycle Rate% | 50 | 50 | 50 | 50 | 50 | 50 |

| No Load Voltage V | 1.08-7.02 | 1.12-7.38 | 1.26-8 | 1.3-8.5 | 2.2-9.0 | 1.3-9.7 |

| Max. Welding Thickness mm | 1.2+1.2 | 1.5+1.5 | 1.8+1.8 | 2+2 | 2.5+2.5 | 2.5+3 |

| Upper Wheel Stroke mm | 20-80 | 20-80 | 30-100 | 30-100 | 30-100 | 30-100 |

| Welding Speed m/min | 0.6-4 | 0.5-3.2 | 0.5-2.8 | 0.5-1.5 | 0.5-1.2 | 0.5-1.2 |

| Max. Pressure KN | 6.3 | 6.3 | 8.6 | 8.6 | 8.6 | 8.6 |

| Compressed Air Mpa | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 |

| Cooling Water Consumption L/h | 820 | 960 | 1080 | 1080 | 1080 | 1080 |

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out with the suitable technical proposal based on your samples or drawings.

Application Industry of The Seam Welding Machine

Suitable for the welding of sheet, barrel body, box and sealed thin-wall container with different material, such as carbon steel, stainless steel, titanium, nickel and other materials. For fuel tank of automobile, damper of motorcycle, detector of temperature controller, nickel strap of battery, oil heater, power capacitor, sieve iron basket, water pump manufacturing, tin making, coopery industry, etc.

Factory & Certificate