Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

HWASHI Multi Head Sheet Metal Welder Door Panel Multi Spot Welding

Machine

Description

This Door Panel Multi Head Spot Welding Machine adopts multiple

welding heads with automatic welding. You can choose multi head

welding at the same time or each head welding in turns. It is

suitable for door panel or sheet metal multi spot welding.

The effective welding width is 1000mm to 2000mm while the effective

welding length is 300mm (customized). The material thickness is

ranging from 0.4mm to 1.5mm.

Working Process

* Manually put the workpiece onto the table;

* Press the start button, then the machine will conduct welding

automatically for one line of spots;

* After welding one line, then manually move the product to another

line. Then press the start button again.

* Cycle working

Features

Parameter

S.N | Items | WL-SF-MF160K | WL-SF-MF120K | WL-SF-MF100K |

1 | Input Voltage | 380V,3-Phase | 380V,3-Phase | 380V,3-Phase |

2 | Input Power | 160KVA | 120KVA | 100KVA |

3 | Max.Welding Current | 32000A | 30000A | 28000A |

4 | Max. Electrode Force | 2.2KN | 2.2KN | 2.2KN |

5 | Welding Capacity | 3+3mm | 2+2mm | 1+1mm |

Welding samples

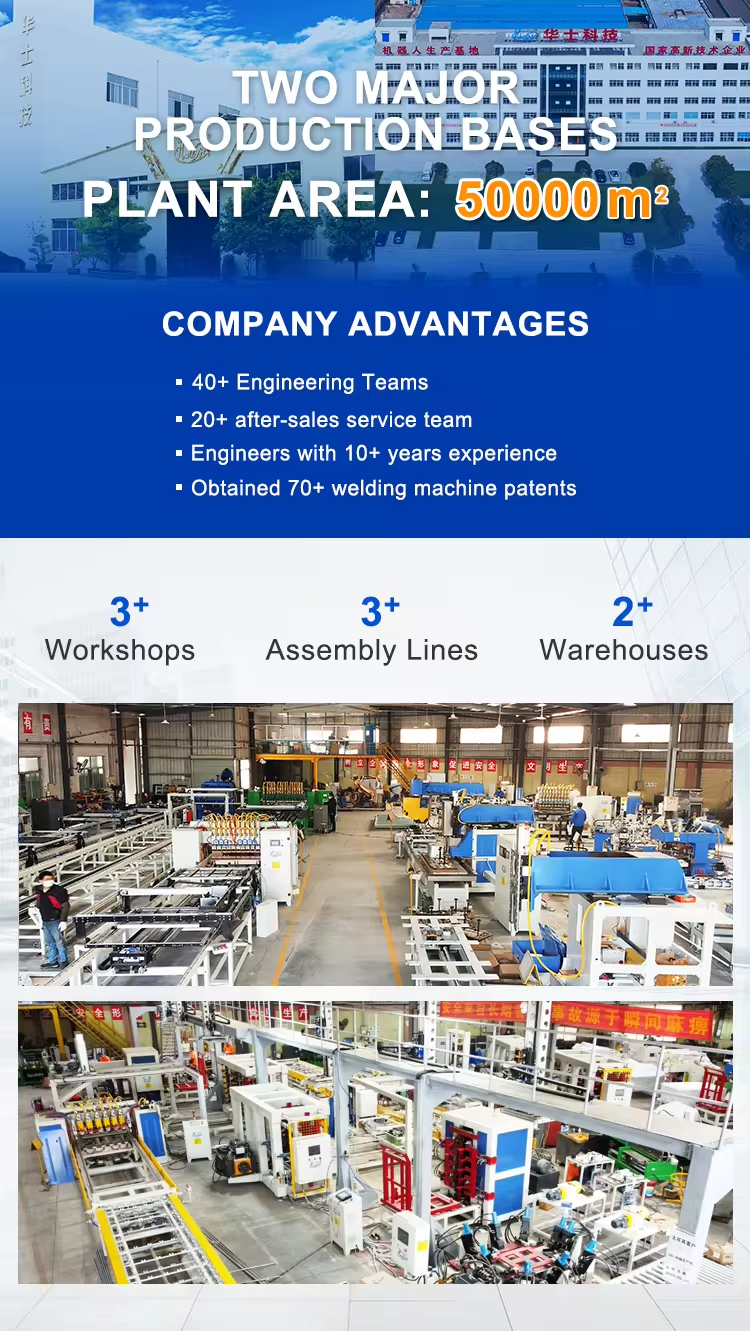

Our company

Cooperated Customers