Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

high alumina content thermal lightweight mullite insulating brick

high alumina content thermal lightweight mullite insulating brick ccording to the different use of temperature production of multiple grades of mullite lightweight insulation brick is divided into JM23 / JM26 / JM28, the use of temperature range from 1100C-1650C, the ratio of each product is specially designed to meet the different thermal and Physical requirements.

Characteristics of high alumina content thermal lightweight mullite insulating brick

high alumina content thermal lightweight mullite insulating brick with the characteristics of High strength, high impurity content; high temperature, can be directly exposed to the flame (this is very important), resistant to various atmosphere corrosion; low thermal conductivity, low melting; high strength, and excellent thermal shock resistance; high dimensional accuracy.

Physical&Chemical Index:

Item | JM23 | JM26 | JM28 | JM30 |

AL2O3(%) | 38-44 | 50-58 | 65-70 | 70-73 |

Fe2O3(%) | 1.0 | 0.9 | 0.8 | 0.7 |

Classification Temperature (℃) | 1350 | 1430 | 1540 | 1600 |

Bulk Density (g/cm3) | 0.8-1 | 0.8-1 | 0.8-1 | 0.8-1 |

Reheating Linear Change (%) CT-30 ℃X 8H | 1250℃ -0.5 | 1400℃ -0.5 | 1500℃ -0.5 | 1550℃ -0.5 |

Cold Crushing Strength (Mpa) | 3.0-4.5 | 3.0-4.5 | 3.0-4.5 | 3.0-4.5 |

Modulus of Rupture (Mpa) | 1.5 | 1.7 | 1.8 | 2.0 |

Thermal conductivity400℃(W/m.k) | 0.25 | 0.27 | 0.32 | 0.41 |

Thermal Expansion1000℃(%) | 0.5 | 0.7 | 0.8 | 0.9 |

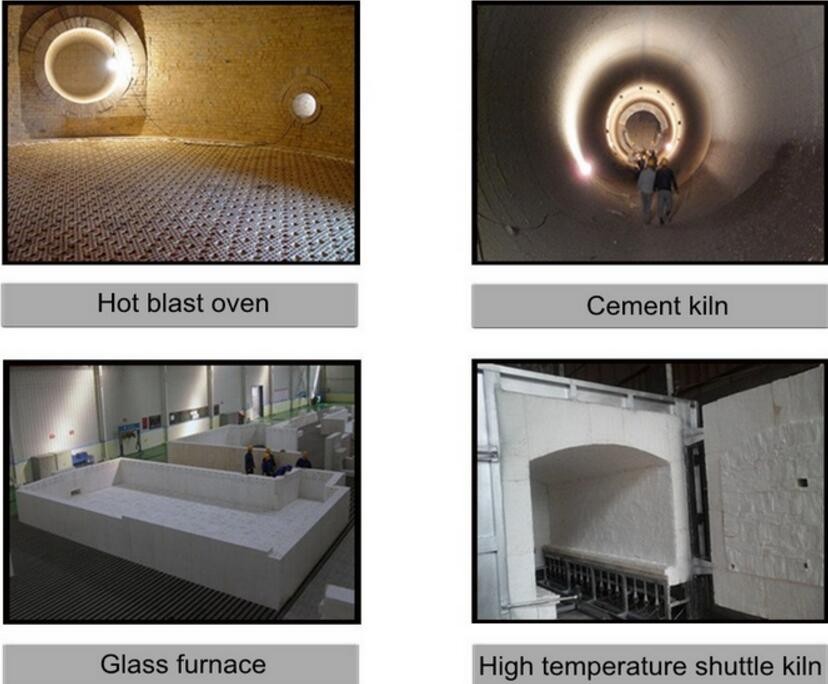

Application of high alumina content thermal lightweight mullite insulating brick:

1) Lining of high-temperature kilns of industrial ceramics, industrial furnaces under 1650C of petrochemical, metallurgy and machinery industries

2) Lining of hot-surface of industrial furnaces as carbon furnace, cracking furnace, heating furnace for oil refining, roller kiln, tunnel kiln.

3) Back lining insulating layer of industrial furnace as glass tank kiln.

4) Atmosphere furnace.

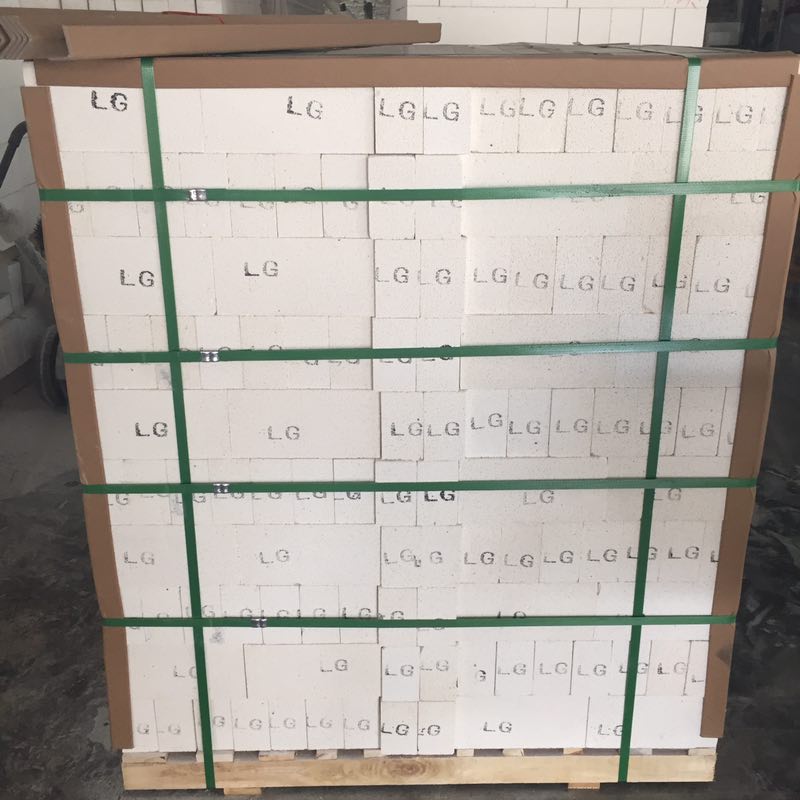

Packaging details:

high alumina content thermal lightweight mullite insulating brick is packaging with fumigated wooden pallet, using paper or non-woven fabrics between layers separated,plastic shrink film protected outside.finally using straps. Or as your requirements.

Shipping details:

high alumina content thermal lightweight mullite insulating brick is transported by vessel or train from Chinese ports.

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000

tons.

3.Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

Korea, Vietnam, Pakistan, Bulgaria, French, India,

Egypt,Congo, Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

2. What's your delivery time?

It usually needs about 15days- 30 days after receiving the deposit.

3.Do you have any experiences of export?

Yes,and Now we have gained a global sales network reaching Taiwan, Russia, Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo, Angola, South Africa, and so on.

4. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock, The quantity based on the material type, The buyer should bear all the shipping costs.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

Contact informations: