Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kiln

Alumina Bubble Brick uses the alumina hollow ball as the main raw

material, high-performance powder as additives, and organic

material as the temporary binding agent. After mixing, drying,

forming, firing at high temperature shuttle kiln, it is made. The

material is widely used in carbon black furnace, gasifier, gas

furnace, hydrogen furnace, as well as shuttle kilns and other

high-temperature furnace equipment. Products, dimensions, physical

and chemical indicators of useful life are up to customers'

requirements. The company produces lightweight insulation

refractory material with high purity, mechanical strength and low

thermal conductivity. The material is fireproof and anti-spalling.

It can be used as insulation lining and the high-temperature

furnace lining of other industries.

alumina bubble brick is made of alumina hollow ball as raw

material, high-performance powder as additive, and organic material

as the temporary binding agent, after mixing, drying, forming,

firing at high temperature in shuttle kiln, the whole process is

finished.

The quality of alumina bubble brick has reached or exceeded the

level of similar products at home and abroad.

Alumina Bubble Brick Features:

1. Excellent thermal shock resistance, low thermal conductivity and

good performance of insulation.

2. High temperature resistance as Al2O3 content is≥85%.

3. Reduce furnace weight as there are amount of closed pores in

alumina bubble brick.

4. Strong ability to resist erosion of gas and slag.

5. Direct contact with flame.

99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kiln

| Index | KGSM1650 | Alumina hollow ball | Alumina hollow ball | Alumina hollow ball |

| Max.Service Temp, % | 1630 | 1680 | 1700 | 1800 |

| AL2O3,% ≥ | 75 | 90 | 96 | 99 |

| Fe2O3,% | 0.5 | 0.2 | 0.2 | 0.15 |

| Bulk Density g/cm3 | 1.2 - 1.5 | 1.4 - 1.7 | 1.4 - 1.7 | 1.4 - 1.7 |

| Cold Crushing Strength MPa | 8 - 10 | ≥ 20 | ≥ 20 | ≥ 19 |

| Bending Strength MPa | 4.5 | 5.8 | 5.8 | - |

| Reheating Linear Change≤ | 0.38 (1600ºC × 8 hours) | -0.2 (1650ºC×8 hours) | - 0.2 (1650ºC ×8 hours) | ±0.3 (1650ºC× 8 hours) |

| Thermal Expansivity≤ | 0.56 (1000ºC) | 0.67 (1000ºC) | 0.67 (1000ºC) | 0.86 (1300ºC) |

| Thermal Conductivity ( 300ºC±25ºC) | 0.8 | 1.0 | 1.0 | 1.0 |

Note :

Size Tolerance : + / - 1.5 % or + / - 2 Mm Which

Ever is Greater Above Specified Values Relate to Machine Pressed Standard

Bricks. P L C Values are for Specimens Heated At Given Temp. for 2

Hours

Alumina Bubble Brick Specifications

1.High temperature resistance.

2.Good thermal insulation.

3.Professional manufacturer.

99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kiln

Alumina Bubble Brick Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Alumina Bubble Brick is widely used in carbon black furnace, gasifier, gas furnace, hydrogen furnace, as well as shuttle kilns and other high-temperature furnace equipment. can be used as insulation lining, but also can be used as the work of other industrial high-temperature furnace lining.

99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kiln

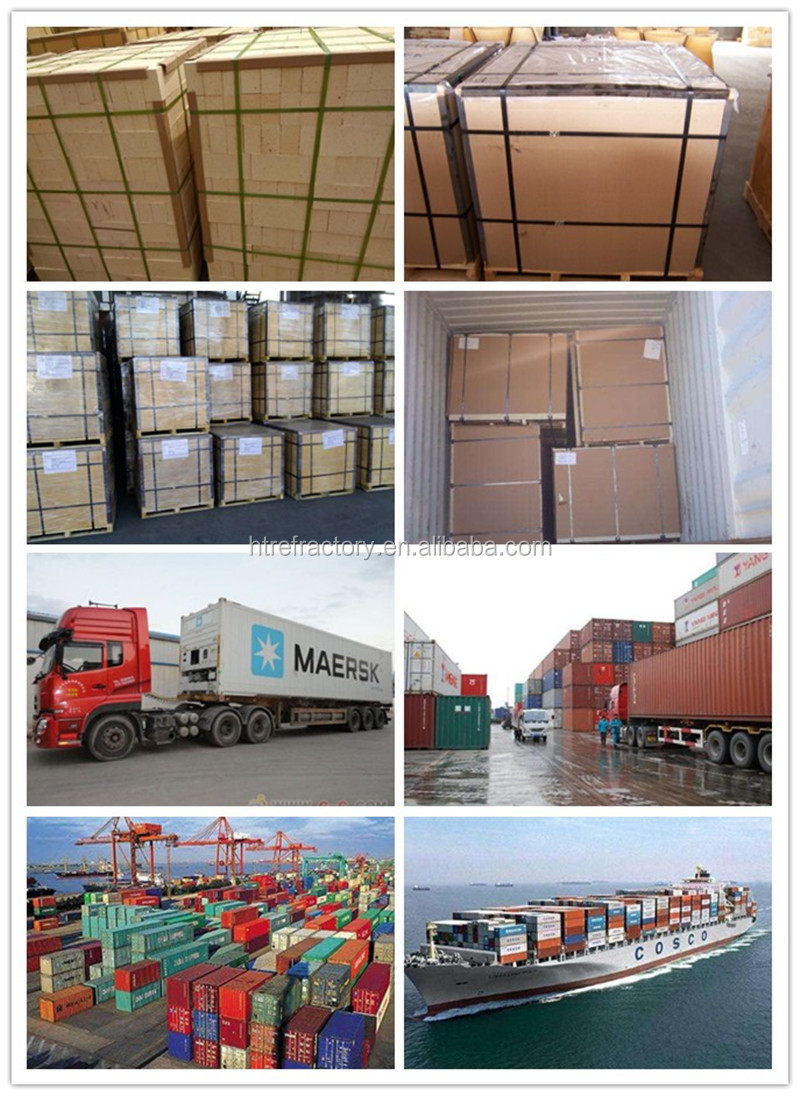

Packaging of Alumina Bubble Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 0.5-1.0tons,

Shipping of Alumina Bubble Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kiln

Starting from the raw material into factory, Alumina Bubble Brick every production process of our product should through strict quality control, In addition to rigorous process control, our quality control team inspects the output of each process to ensure material quality and consistency. We do our best to supply the products with best quality to satisfy our customers.

Why Choose us?

Our refractory bricks have passed the ISO international certified. High purity raw material, scientific formula, advanced technology and professional guide all contribute to our qualified 99% Al2O3 Bubble Alumina Brick for Industrial Ceramic Furnace Kilnproduction. Over 30 years producing and marketing experience, we have developed stable customer base overseas and kept long-term cooperation. Need refractories for high temperature furnace fuel? Contact us, We will never let you down.

Q1: How about your factory’s annual production capacity?

A1:HongTai annual production is about 310,00Tons.

Q2: How many production lines of your factory?

A2:HongTai has 6 production lines, including eight silicon bricks

lines, and each one of mullite brick, high alumina brick,

insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: HongTai covers almost 200,000 Square meters, including plant

area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:HongTai main products are: refractory for hot blast stove,

refractory for coke oven, refractory for glass kiln, refractory for

carbon calcining furnace.