Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

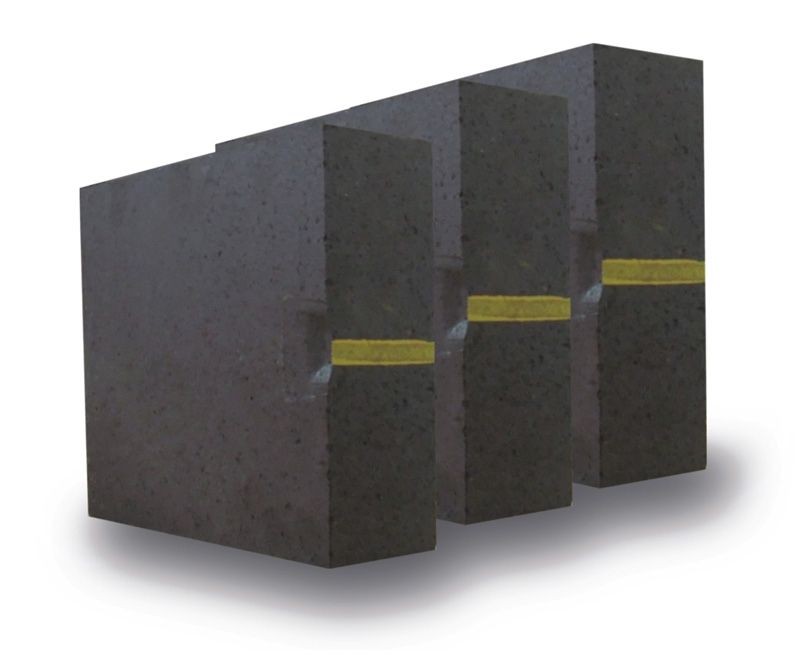

High fired magnesite chrome refractory bricks for glass furnace

Magnesium chrome brick magnesia (MgO) and chromium oxide (Cr2O3) as the main ingredient, periclase and spinel as the main mineral components of refractory products. Such brick high refractoriness, high temperature strength, resistance to basic slag erosion resistance, excellent thermal stability, acidic slag also has some adaptability. The main raw material to manufacture magnesium chrome brick is sintered magnesia and chromite. Purity magnesia raw material to be as high as possible, the requirements of the chemical composition of chromite is: Cr2O3: 30 ~ 45%, CaO1.0 ~ 1.5%.

High fired magnesite chrome refractory bricks for glass furnace

Fused re-bonded magnesia chrome brick:

The magnesia chrome refractory for RH refining device developed by the Company has the characteristics of high purity.high fire resistance and good thermal stability.It’s applicable to large.medium and silicon steel RH refining devices, This project is tested on the RH silicon steel device in Wuhan lron & Steel.and the tested service life was increased by 20%.

The burnt high fired magnesite chrome bricks are made out of high-quality magnesite and chrome ore fine charge mixture.According to different demands,adjust the content of Cr2O3,The product thermal stability and high-temperature performance are satisfactory,It’s widely used in the cement kiln and nonferrous metallurgical furnace etc.

1.Direct bonding high fired magnesite chrome bricks choose the raw materials of chrome ore with low impurity content and magnesite with high quality and high purity,and adopt the high-pressure forming and over 1700℃ high-temperature sintering.The high-temperature performance is satisfactory,and the metallurgical slag corrosion resistance is strong.It can resist the corrosion of cement clinker,It’s widely applied in the electric furnace lining for steel making,nonferrous metallurgical furnace and cement rotary kiln etc.

2.The semi-rebonded high fired magnesite chrome bricks and rebonded high fired magnesite chrome bricks all or partially use the fused sand(fused synthetic clinker)as the raw materials,choose the fine charge mixture and adopt the high-pressure forming and super-high-temperature burning.The products have good particle bonding degree,high product strength and good volume stability.They are widely used in the secondary refining devices like RH,VOD and AOD,and nonferrous metallurgical furnace as well.

High fired magnesite chrome refractory bricks for glass furnace

Description of high fired magnesite chrome bricks

High strength

Corrosion resistance

Erosion resistance

Excellent slag resistance

Good thermal shock stability

Advantage of high fired magnesite chrome bricks

The directly bonded magnesia-chrome brick has high temperature resistance, good corrosion resistance, thermal shock resistance and bulk stability under high temperature etc.

High fired magnesite chrome refractory bricks for glass furnace

Chemical & Physical Data Of high fired magnesite chrome bricks

Brand | MgO % | Cr2O3 % | SiO2 % | A.P. % | BDg/cm3 | CCS.MPa | R.U.L ℃ |

LADBMGe-8A | ≥74 | ≥8 | ≤1.5 | ≤18 | 2.98 | ≥40 | 1660 |

LADBMGe-8B | ≥74 | ≥8 | ≤2.0 | ≤18 | 2.98 | ≥35 | 1600 |

LADBMGe-12A | ≥66 | ≥12 | ≤1.5 | ≤18 | 3.1 | ≥40 | 1660 |

LADBMGe-12B | ≥66 | ≥12 | ≤2.0 | ≤18 | 3.1 | ≥35 | 1600 |

LADBMGe-16A | ≥60 | ≥16 | ≤1.5 | ≤18 | 3.15 | ≥40 | 1660 |

LADBMGe-16B | ≥60 | ≥16 | ≤2.0 | ≤18 | 3.15 | ≥35 | 1600 |

Main Application:It’s mainly applied to line the sintering zone of the new dry-processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

Brand | MgO % | Cr2O3 % | SiO2 % | A.P. % | BDg/cm3 | CCS.MPa | R.U.L ℃ |

LARBMG-16A | ≥65 | ≥16 | ≤1.2 | ≤16 | 3.1 | ≥45 | 1750 |

LARBMG-16B | ≥60 | ≥16 | ≤1.6 | ≤16 | 3.1 | ≥40 | 1700 |

LARBMG-20A | ≥60 | ≥20 | ≤1.2 | ≤16 | 3.15 | ≥45 | 1750 |

LARBMG-20B | ≥60 | ≥20 | ≤1.2 | ≤16 | 3.15 | ≥40 | 1700 |

Main Application:It’s suitable for lining of the slag zone area of refining furnaces of VOD,SKF.

Brand | MgO % | Cr2O3 % | SiO2 % | A.P. % | BDg/cm3 | CCS.MPa | R.U.L ℃ |

LASBMG-16A | ≥60 | ≥16 | ≤1.5 | ≤17 | 3.1 | ≥40 | 1750 |

LASBMG-16B | ≥60 | ≥16 | ≤1.8 | ≤17 | 3.1 | ≥35 | 1700 |

LASBMG-20A | ≥55 | ≥20 | ≤1.5 | ≤17 | 3.15 | ≥40 | 1750 |

LASBMG-20B | ≥55 | ≥20 | ≤1.8 | ≤17 | 3.15 | ≥35 | 1700 |

Main Application:It’s widely used for every industrial furnaces of the metallurgical and building materials industry.

High fired magnesite chrome refractory bricks for glass furnace

Packaging of high fired magnesite chrome bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of high fired magnesite chrome bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

High fired magnesite chrome refractory bricks for glass furnace

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of high fired magnesite chrome

bricks again in factory.

High fired magnesite chrome refractory bricks for glass furnace