Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Refractory Zirconia Nozzle Core For Steel Ladle

Description of Zirconia metering nozzle

The Zirconia Metering Nozzle is made of stabilized zirconium oxide and imported natural oblique zircon after being stabilized by a special process, and then formed by high pressure molding and high temperature firing. The steel environment and use can be set according to the different refinement requirements of users.

As a key functional refractory used in billet continuous casting, sizing nozzle plays an important role in controlling the flow of molten steel from tundish to mould evenly and stably, stabilizing the casting speed and maintaining the height of liquid level in mould, so as to ensure the quality of billet and improve the efficiency of continuous casting, and its quality directly affects the duration of continuous casting.Tundish stopper gating system is shown in figure 1, from the picture you can see, the structure design of the sizing nozzle is divided into two parts, the upper approximation of streamlined, molten steel through sizing nozzle flow to the crystallizer, approximate streamlined structure design can ensure the molten steel and nozzle face steel surface (flow) of small resistance, stable flow of molten steel flow to the crystallizer, there would be no steel leakage, and the structure design of steel produced by the disturbance is small, can be reduced to a certain extent and improve the erosion resistance of shuikou products, and then to prolong the time of nozzle, improve the service life of the nozzle;The longer part of the lower part is the sizing section, which ensures that the molten steel flows evenly and stably from the tundish into the mold.In the casting process, the inner diameter of the fixed-diameter nozzle for tundish should basically remain unchanged, because the fixed-diameter nozzle plays a role in controlling the flow rate of molten steel. If the expansion of the inner diameter is too large, the continuous casting can not be carried out normally, thus affecting the production efficiency of continuous casting. Therefore, the anti-erosion and anti-erosion properties of the fixed-diameter nozzle are high.

With the reform and improvement of continuous casting technology and functional refractories, zirconium sizing nozzle is the most commonly used in China.According to the different content of zirconia in the sizing nozzle, the zirconia sizing nozzle can be divided into two categories: ordinary type sizing nozzle and zirconia type sizing nozzle. The content of ZrO2 in the zirconia inlaying in the ordinary type sizing nozzle is less than 85%.The content of ZrO2 in zirconium inlay of ZrO2 type sizing nozzle is more than 85%.

| ZrO2+HfO2% | ≥ | 93 | 94 | 95 |

| Bulk Density (g/cm3) | ≥ | 5 | 5.2 | 5.4 |

| Apparent Porosity % | ≤ | 8 | 7 | 6 |

| Cold Crushing Strength(Mpa) | ≥ | 90 | 100 | 100 |

| Refratoriness under Load 0.2Mpa(°C) | ≥ | 1790 | 1790 | 1790 |

Due to the different production technology, the ordinary type of

sizing nozzle can be divided into four kinds: homogeneous sizing

nozzle, direct composite sizing nozzle, vibration forming sizing

nozzle and inlaying sizing nozzle.

(1) Fully homogeneous sizing nozzle

The fully homogeneous sizing nozzle is mainly made of zirconia and

a small amount of zirconite by mixing, forming, drying and

sintering at 1620-1650℃ in a certain proportion. Because of the

content of zirconia is 60-90%, so its advantages are good

uniformity of composition and structure, high strength, high

corrosion resistance, safe and reliable use, but the disadvantage

is higher production cost, and short life.

(2) Direct compound sizing nozzle

The body of the direct composite sizing nozzle is made of

zirconium, and the working face of the sizing end of the nozzle is

made of zirconium and 72%-78% zirconia. The composite parts of the

body and the working face are formed at the same time and fired at

1620-1650℃ in one time. The structure is shown in Fig. 3.The

advantages of this nozzle are good integrity, not easy to fall off

during use, and the production cost is much lower than that of the

full uniform diameter orifice, but due to the martensitic

transformation of zirconia and its attendant volume change, it is

easy to make the nozzle burst phenomenon in the process of

use.Therefore, the nozzle must use stable zirconia as the raw

material, but the content should not be too high.Zircon zirconium

oxide and the expansion coefficient of differences, making shuikou

easily when nozzle cracking phenomenon, in order to avoid this

problem, the need to minimize the difference of expansion

coefficient, as a result, the end face of nozzle diameter of

zirconia content should be controlled in 70-80%, but it is bad for

the improvement of sizing shuikou life.

(3) Vibration forming sizing nozzle

The vibration forming sizing nozzle is composed of nozzle body,

nozzle core and iron shell. The nozzle body is made of high

aluminum material, while the nozzle core is made of zirconium and

zirconia composite, and the firing temperature is 1620-1650℃

The nozzle is made of pre-prepared nozzle core, high aluminum

material and iron shell by means of vibration pressure. After

forming, it can be dried without burning.The advantages of this

nozzle are simple production and preparation technology and low

production cost. The disadvantage is that after long time use, it

is easy to cause steel leakage accidents.

(4) Mosaic type sizing nozzle

Mosaic sizing nozzle body is made from high aluminium material,

nozzle core made of zircon and zirconium oxide compound,

respectively, and then use refractory mortar bond between the two

as a whole, therefore, if the shuikou ontology and nozzle core

bonding is not good, long time use the nozzle core will appear fall

off phenomenon, due to continuous casting production can not be

normal, but the nozzle has the advantage of low production cost,

good thermal stability.

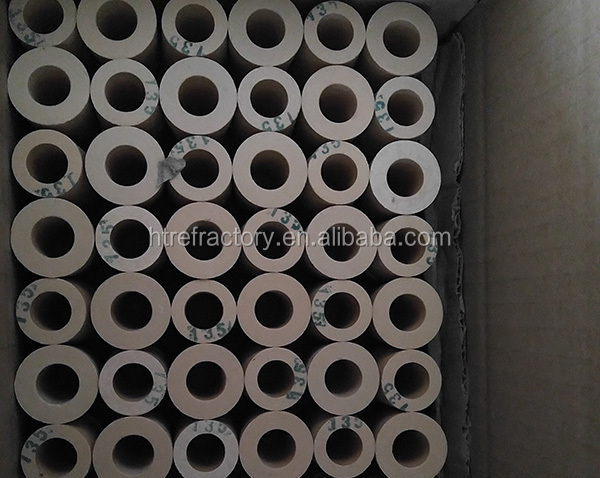

Packing of Zirconia Metering Nozzle

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Packaging

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request

Packaging of SK37 High Alumina Refractory Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of SK37 High Alumina Refractory Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample of dry ramming mass

Sample and trial order are accepted for the quality evaluation

3.Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;offer relative export documents and original certificate if needed;warm and considerable after-sale service.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our

aim."Scientific management, strong technical force, perfect testing

means, advanced technological equipment and stable product quality

are the guarantee of quality service.Henan hongtai kiln

refractories co., LTD sincerely hopes to cooperate with you hand in

hand and in good faith.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick,

wear-resistant pouring material, corundum pouring material, low

cement high strength pouring material, impermeable material,

self-flowing material, plastic material, and various types of

refractory materials.For different industries, the cement industry

with anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, Korea, Pakistan,

kazakhstan, other southeast Asian countries and regions.