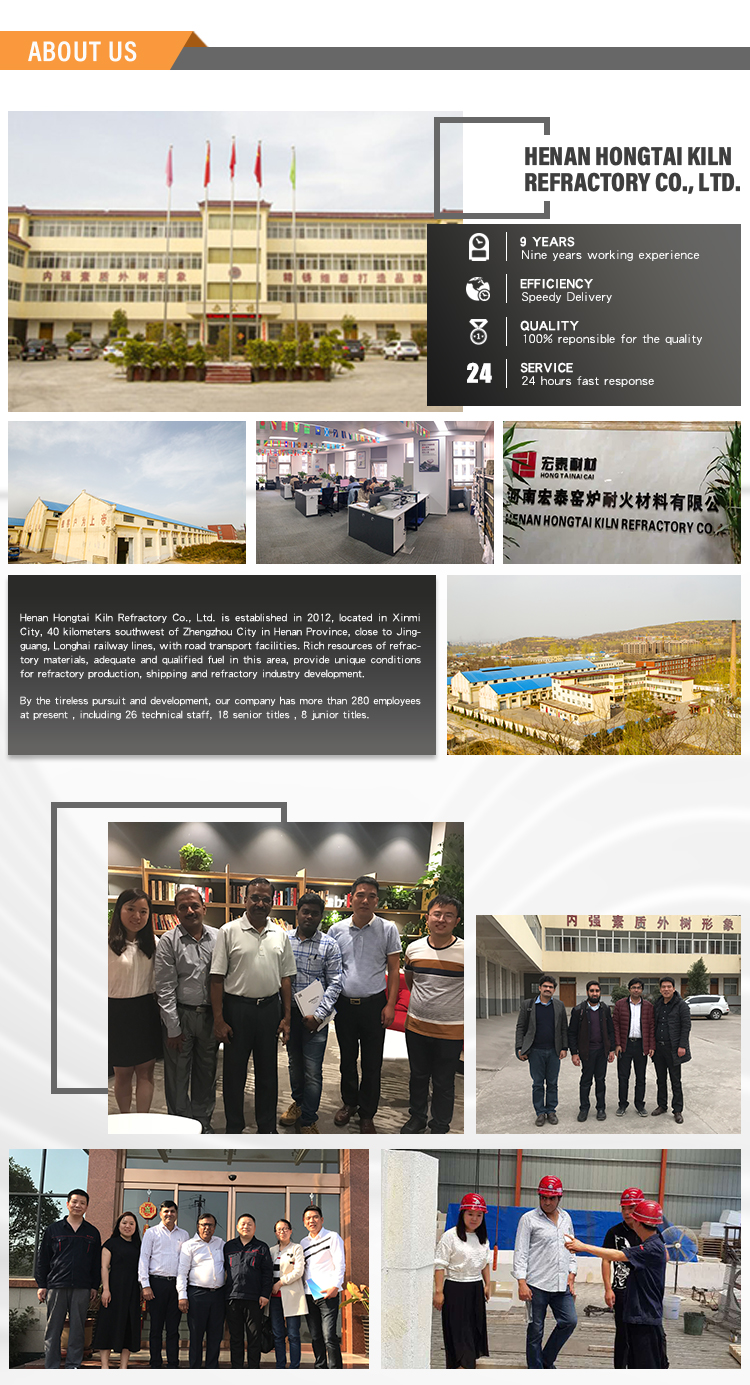

Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Item | Corundum mullite | Mullite | Cordierite mullite |

MgO | - | 5 | 6.5-8 |

AL2O3% | ≥80 | 43-45 | 40-45 |

SiC% | - | - | - |

SiO2% | ≤18 | 46-48 | ≥46 |

Fe2O3% | ≤0.03 | ≤0.7 | ≤0.03 |

Bulk density g/cm3 | ≥2.7 | ≥2.0 | ≥2.2 |

Apparent porosity ,% ≤ | ≤22 | 21-23 | ≤20 |

Cold crushing strength,MPa ≥ | ≥80 | - | |

Thermal shock resistance(1100℃water cold) | ≥30 | ≥50 | ≥60 |