Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

recycled and used graphite carbon brick with low price

Denfinition:

graphite carbon brick (recycled and used graphite graphite carbon brick with low price ) is a neutral refractory product made of carbonaceous as raw materials, adding appropriate amount of binder.

Raw Merterial:

graphite carbon brick raw materials include anthracite, coke and graphite, as well as asphalt, tar and anthracene oil and other bonding agent. AS anthracite volatile less, and has dense structure, graphite carbon brick use it as aggregate, adding metallurgical coke (coal), and asphalt as a binder.

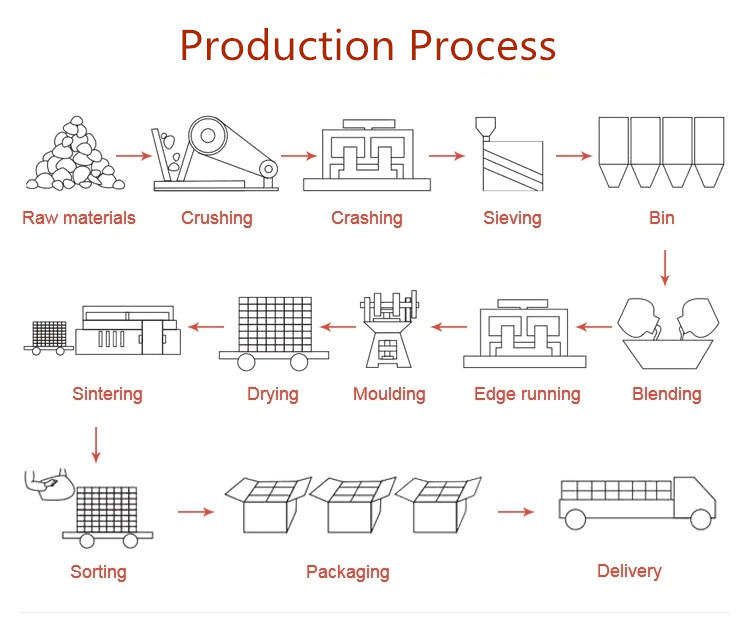

Production process:

the production process of graphite carbon brick is similar with other refractory bricks, but carbon is easy to be oxidized at high temperatures, so the raw materials roasting and products firing must be carried out in a reducing atmosphere. Anthracite should be roasted before use to remove volatile, sulfur, moisture, and increase the volumetric stability, mechanical strength and oxidation resistance of anthracite. Coke should be dried first to avoid molding difficulties due to high moisture content and the product cracking during firing. Asphalt should first melt and dehydration, so that the water content is less than 0.2%, dehydration temperature should be 120 ~ 160 ℃.

graphite carbon brick ingredients are roasted granular anthracite as aggregate, and its particle size depends on the size of the product: anthracite in large brick is 8 to 12 mm, small brick is 4 to 6 mm. Anthracite is about 60%. Coke is added with fine powder state, whose particle size of less than 88 microns should be about 70%. Blast furnace used graphite carbon brick binder is usually added from 15 to 20%. In order to prevent oxidation, the brick in the firing use coke powder or coal powder as protection filler. graphite carbon brick’s firing temperature is 1300 ~ 1450 ℃, holding time is about 20 hours, the total firing time is about 240 to 420 hours,and then cooled to 40 ~ 60 ℃, finally be taken out from the kiln. It is must be paid attention that graphite carbon brick out of the kiln is in high temperature, easy to fired and burn.

Features of graphite carbon brick:

1. good thermal stability,

2. Small thermal expansion coefficient,

3. high temperature resistant,

4. resistant to acid, alkali, salt and organic solvent erosion,

5. but easy to oxidation in the oxidation atmosphere.

Uses of graphite carbon brick:

1. metallurgical industry, such as blast furnace

2. aluminum electrolytic cells

3. pickling tank, plating tank of electroplating industry

4. dissolving tank of paper making industry

5. reaction tank, storage tank of chemical industry

6. autoclave of petrochemical industry and so on.

Spencifications of recycled and used graphite carbon brick

recycled and used graphite carbon brick

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million.

3. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

4. Testing equipment;

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

1.What's your payment terms?

Various payment will be supported

2.What's your delivery time?

Usually within 15-30 days after receive the deposit.

3.How about the packing?

25 kg/bag,outer woven bags with inner plastic lining.

4.What documents you provide?

Usually, we provide Commercial Invoice, Packing List, Bill of

lading, COA , TDS. etc.If your markets have any special

requirements, let us know.

5.How about the validity of the products?

According to the products you ordered.

6.What is loading port?

Usually isTianjin, Shanghai or Qingdao.

Contact person:Marina Ma

Tel:+86 18838001797

Wechat/Whats app:+86 18838001797

Viber/Telegram:+86 18838001797

Skype:Marina Ma

QQ:2262521614

Email:sales04(at)firebricks-supplies.com