Shenzhen Tunsing Plastic Products Co., Ltd. |

|

Verified Suppliers

|

|

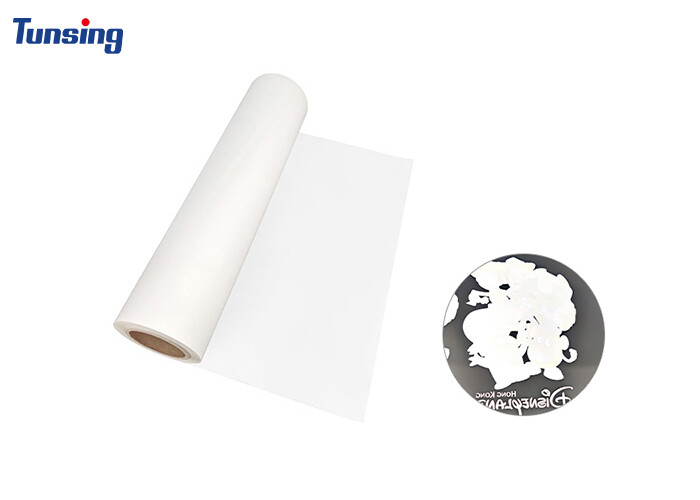

Printing Process: In DTF printing, the design is printed onto the DTF film using a digital printer equipped with sublimation or pigment inks. The film is made with a special coating that can hold the ink and release it during the heat transfer process.

Adhesion Layer: DTF film typically consists of multiple layers, including a base layer, an adhesion layer, and a release layer. The adhesion layer helps the ink adhere to the fabric surface during the heat transfer process.

Heat Transfer: After the design is printed on the DTF film, it is placed onto the fabric with the printed side facing the fabric. Heat and pressure are applied using a heat press machine, which causes the ink to be released from the film and transferred onto the fabric.

Compatibility: DTF film is compatible with various types of fabrics, including cotton, polyester, blends, and even textured or uneven surfaces. It allows for printing on both light and dark-colored fabrics.

Washability: Fabrics printed with DTF film generally exhibit good wash fastness, meaning that the prints maintain their color and quality even after multiple washes.

Durability: DTF film transfers produce durable prints that are resistant to fading and cracking, ensuring longevity of the design on the fabric.

Design Flexibility: DTF film enables the reproduction of intricate and colorful designs with high color saturation and sharpness. It offers flexibility in creating custom designs and patterns.

Dtf Pet Film Physical Characteristics:

Product Specification | Conventional Thickness | 0.075mm, 0.10mm |

| Conventional Length | 100m | |

| Conventional Width | 600mm | |

| Finished Product | 0.075mm*600mm*100m/roll | |

| Operating Conditions | Heat Press Temperature | 130℃-160℃ |

| Heat Press Time | 8-15 seconds | |

| Pressure | 0.3-0.5mpa | |

| Washing Resistance | Washable Temperature | 45℃-60℃ |

| Storage Conditions & Shelf Life | It is strictly forbidden to collide with sharp objects. When opening the package and not using it, please seal it and store it to prevent moisture and high temperature | |

| The storage conditions are temperature -5℃-30℃, humidity 40-80%, avoid direct sunlight, shelf life is one year | ||

Cautions:

1. Tear-off method: cold or hot tear.

2. Printed film is a soft product. It is normal for the surface to be slightly sticky, and the surfaces should be prevented from sticking to each other.

3. Reasonable control of temperature and pressing time. If the temperature is too high or the time is too long, it is easy to cause discolouration or loss of elasticity.

Application of DTF PET Film:

Film Roll Types: DTF film rolls come in different types to accommodate various printing and transfer needs. Some common types include transparent, white, and metallic films. Transparent film rolls are often used when the design requires the fabric color to show through, while white film rolls provide a solid background for vibrant and opaque designs. Metallic film rolls add a metallic or shimmering effect to the transferred design, offering unique visual appeal.

Film Roll Width and Length: DTF film rolls are available in different widths and lengths to suit different printing requirements. The width of the film roll determines the maximum width of the design that can be printed, while the length determines the total amount of film available for printing multiple designs. It's important to consider the dimensions of the design and the fabric being used to select the appropriate film roll size for optimal printing and transfer results.

Printing Techniques: DTF film rolls can be printed using various techniques, including screen printing and digital printing. Screen printing involves using a screen with a stencil of the design, through which the ink is forced onto the film roll. Digital printing utilizes inkjet technology to directly print the design onto the film roll. Both techniques have their advantages and can be chosen based on factors such as design complexity, color accuracy, and production volume.

Ink Compatibility: DTF film rolls are designed to work with specific types of inks that are compatible with the transfer process. The inks used for DTF printing are typically formulated to adhere well to the film and provide vibrant, long-lasting colors. It's important to ensure that the ink being used is suitable for the specific DTF film roll and transfer process to achieve optimal results.

WHY CHOOSE US

1. Customised services

2. Professional after-sales service

3. Low price

4. High quality

Save a lot of cost and money.

Make printing easier.

5. Security

Faster speed and lower cost.

Environmentally friendly Non-toxic and odourless. No toluene.