Beijing Hownew Energy Technology Group Co., Ltd |

|

Verified Suppliers

|

|

Alloy steel is divided into low alloy steel (with alloy elements less than 5%) according to the content of alloying elements; Medium alloy steel (alloy elements at 5% -10%); High alloy steel (with alloying elements greater than 10%), generally speaking, the higher the alloy content, the better the performance of the steel, and the higher the price.

Alloy pipes and fittings have excellent corrosion resistance and high strength, and are widely used in industries such as petroleum, chemical, power, and shipbuilding etc. The characteristics of alloy steel elbows mainly include the following aspects:

Firstly, alloy steel pipe fittings have good pressure resistance and can withstand working conditions in high-pressure environments, ensuring the safe operation of the pipeline system.

Secondly, alloy steel pipe fittings have excellent corrosion resistance, which can resist the erosion of acidic and alkaline media, prolong service life, and reduce maintenance costs.

In addition, alloy steel pipe fittings have the characteristics of good dimensional stability and easy installation, which can meet the needs of different occasions and improve the efficiency of engineering construction.

Manufacturing Process:

The fabrication of alloy steel pipe fittings typically encompasses several stages, commencing with material selection and preparation. High-quality alloy steel is chosen based on the intended application and performance requirements. Following material selection, the steel is subjected to forging or cold forming operations, utilizing specialized dies or presses to shape the material into the desired fitting geometry. Heat treatment, such as quenching and tempering, is then performed to enhance the material's mechanical properties, including strength, hardness, and ductility. Final finishing processes like machining, grinding, and coating may also be applied to ensure dimensional accuracy and corrosion resistance.

Working Principle:

The fundamental working principle of alloy steel pipe fittings is to redirect the flow of fluids within a piping system. These fittings, installed at various points in the pipeline, alter the direction of fluid flow by connecting pipes at angles or providing bends and elbows. By doing so, the fittings ensure smooth and efficient fluid navigation throughout the system, maintaining the intended flow patterns and pressures. Alloy steel pipe fittings are designed to withstand the rigorous demands of industrial applications, including high pressures, temperatures, and potential exposure to corrosive environments.

This description provides a more comprehensive overview of the manufacturing process and working principle of alloy steel pipe fittings, highlighting the various stages of production and the essential role these fittings play in the overall performance of a piping system.

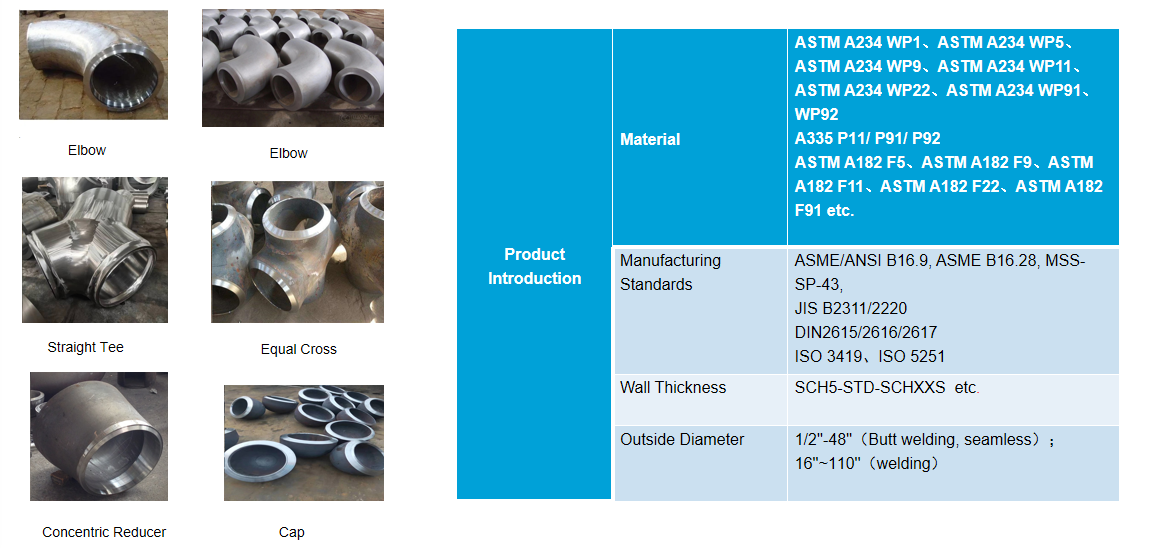

Our company can produce carbon steel, stainless steel, and alloy steel pipe fittings according to standards such as ASME/ANSI, JIS, DIN, ISO etc. The varieties include equal diameter tees, reducing tees, tees, elbows, cross, concentric reducer, eccentric reducer etc. We provide the very best quality pipe and fittings, prompt delivery and reliable services at competitive prices.