Beijing Hownew Energy Technology Group Co., Ltd |

|

Verified Suppliers

|

|

Alloy pipes and fittings have excellent corrosion resistance and high strength, and are widely used in industries such as petroleum, chemical, power, and shipbuilding etc. The characteristics of alloy steel elbows mainly include the following aspects:

In addition, alloy steel pipe fittings have the characteristics of good dimensional stability and easy installation, which can meet the needs of different occasions and improve the efficiency of engineering construction.

The manufacturing process of alloy steel pipe fittings usually includes processes such as material preparation, forging or cold stamping, and heat treatment. The working principle is to change the direction of the pipeline to achieve fluid steering and maintain the normal operation of the pipeline system.

Steel grade: WP92

Chemical composition,%:

C: 007-0.13

Mn: 0.30-0.60

P: ≤ 0.020

S: ≤ 0.010

Si: ≤ 0.50

Cr: 8.5-9.5

Mo: 0.30-0.60

Ni: ≤ 0.40

Al: ≤ 0.02

B: 0.001-0.006

Nb: 0.04-0.09

N: 0.030-0.070

Ti: ≤ 0.01

W: 1.50-2.00

V: 0.15-0.25

Zr: ≤ 0.01

Tensile performance:

Tensile strength, MPa: 620-840

Yield strength, MPa: ≥ 440

Elongation rate:

Standard circular or proportional small-sized specimens,% in 4 D:

longitudinal ≥ 20, transverse ≥ 13

Hardness: ≤ 269 HB

Heat treatment:

Normalizing and tempering. The normalizing temperature range is

1040 ° C-1080 ° C, and the tempering temperature range is 730 °

C-800 ° C.

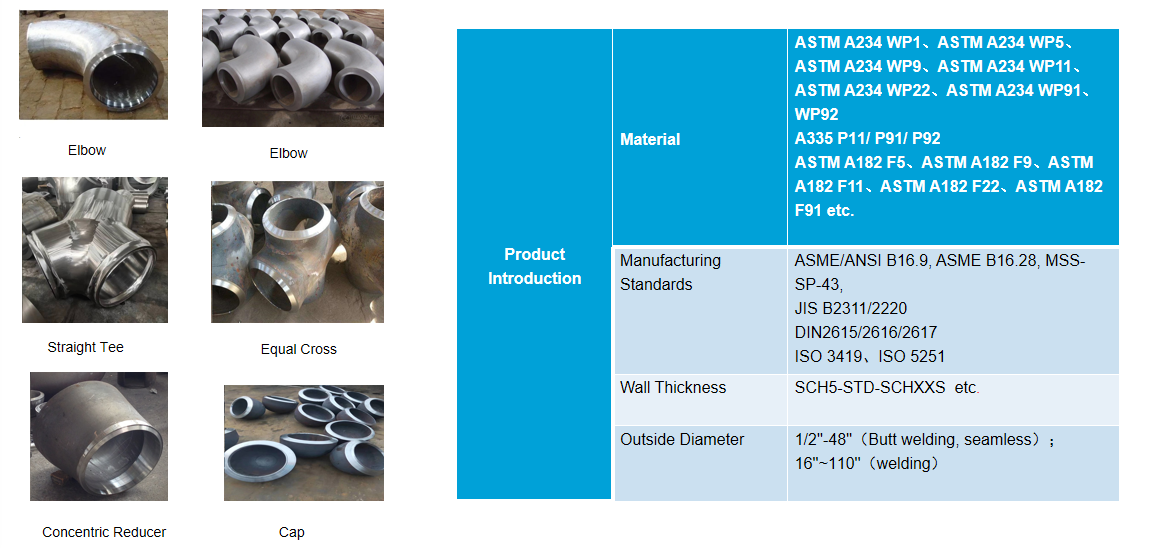

Our company can produce carbon steel, stainless steel, and alloy steel pipe fittings according to standards such as ASME/ANSI, JIS, DIN, ISO etc. The varieties include equal diameter tees, reducing tees, tees, elbows, cross, concentric reducer, eccentric reducer etc. We provide the very best quality pipe and fittings, prompt delivery and reliable services at competitive prices.