Wuxi YBT Machinery Equipment Co.,Ltd. |

|

Full automatic N95 surgical mask making machine with CE certificate

This production line is a fully automatic one-to-two face mask machine, one body machine drives two ear band machines. After the main body machine outputs the mask body, the mask body sheet is conveyed to the turning mechanism by a conveyor belt structure. The reversing mechanism is used to flip the mask plate onto the belt connected to the ear band machine, and then the mask sheet is conveyed to the first mask plate on the front of the ear band machine through the conveyor belt, and finally the mask sheet is placed on the ear band by the cylinder pressing In the mask plate of the machine, the ear band machine is used to complete the welding of the ear bands of the mask and the edging, thereby completing the production of an ear band mask product.

| Machine Name | Fully Automatic N95 Face Mask Making Machine |

| Machine size | 9650*2140*1500mm |

| Ear loop length | 130mm+20mm |

| Media width | 300mm |

| Product capability | 35-40pcs/min |

| Power supply | 380v/50Hz, 220V/60Hz |

| Feature | Full automaticlly make n95 fold type face masks |

Machine features:

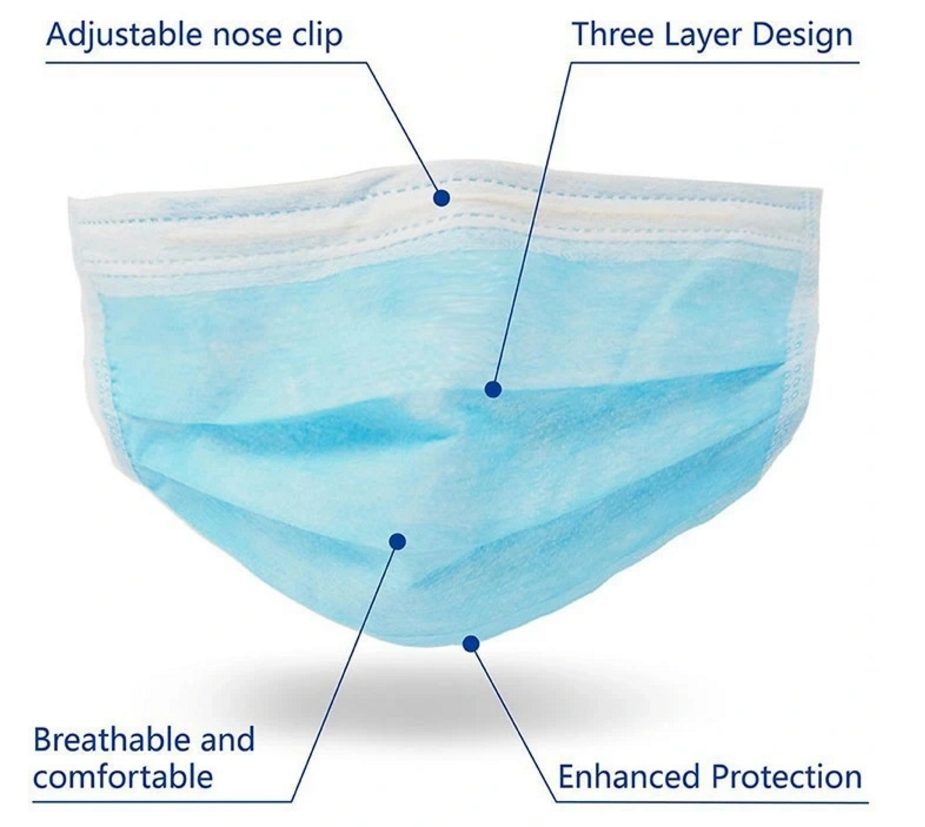

1. Fully automatically produces folding masks from raw materials (3-6 layers) to finished product output.

2. Advanced design concept and mature technology, can meet the needs of various folding masks.

3. With high production efficiency, folding and molding to be precision, can welding firm, beautiful and strong tension ear loop, also automatically put nose bridge strips and printing letters.

4. Stable operation, with a long time of continuous action, the product

qualification rate of more than 98%.

5. Full automatic control of the whole process, operate smoothly and keep stable production.

This production line is a fully automatic one-to-two face mask machine, one body machine drives two ear band machines. After the main body machine outputs the mask body, the mask body sheet is conveyed to the turning mechanism by a conveyor belt structure. The reversing mechanism is used to flip the mask plate onto the belt connected to the ear band machine, and then the mask sheet is conveyed to the first mask plate on the front of the ear band machine through the conveyor belt, and finally the mask sheet is placed on the ear band by the cylinder pressing In the mask plate of the machine, the ear band machine is used to complete the welding of the ear bands of the mask and the edging, thereby completing the production of an ear band mask product.