Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

Higher Productivity Induction Hardening Machine For Surface Hardening of Steel Screws

WHAT IS INDUCTION HARDENING?

Induction is used to elevate the surface temperature of steel or other alloy in order to improve the wear resistance or to treat a select region of the material.

Induction hardening is a heat treatment method that involves the heating of a metal part using induction and quenching. The quenched metal goes through a process called a martensitic transformation, which increases both the hardness and brittleness of the metal part.

Induction heating has many uses and applications, one of which involves the process of induction hardening. The top three benefits of induction hardening are:

| Name | 250KW DSP Digital Control Induction Annealing Equipment For Stainless Steel Tube Annealing

| Application | Stainless steel annealing |

| Work power | 340V-430V | Out power | 250KW |

| Product size | main : 1090*650*1610MM | Certificate | CE,SGS, ROHS |

| transformer : 1070*480*850MM |

The paramerters of 250KW DSP Digital Control Induction Annealing Equipment For Stainless Steel Tube Annealing:

| Model | GYMD-250AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 375A |

| Output power | 250KW |

| Fluctuating frequency | 1-81KHZ |

| The flow rate of cooling water | 0.08-0.16Mpa 12L/Min |

| Water temperature protection point | 50C |

| Product size | main : 1090*650*1610MM |

| transformer : 1070*480*850MM | |

| Net weight | main : 258kg |

| transformer : 178kg |

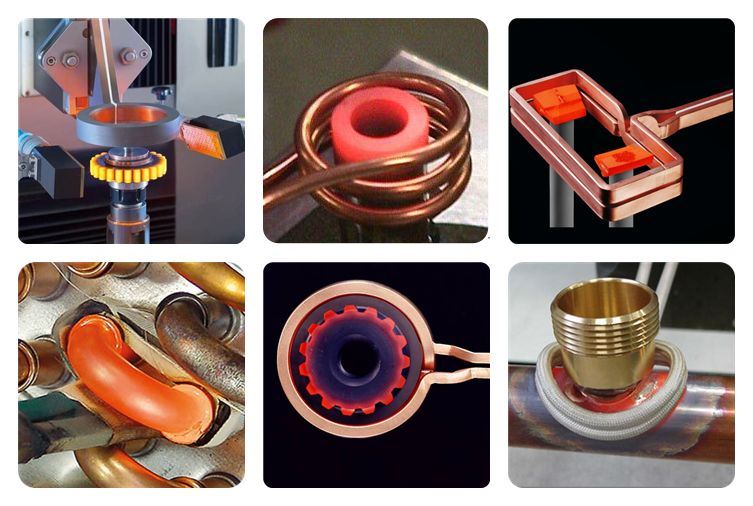

APPLICATION RANGE:

1. Heat treatment of metals: hardening, tempering, and annealing.

The process of induction hardening is most commonly used in steel alloys. This is because there are many mechanical parts, including gears, shafts, and springs, that are subjected to surface treatments prior to delivery in order to enhance what is known as wear behavior. However, it's important to keep in mind that the level of effectiveness of any given induction hardening treatment depends on a variety of factors, including the modification of surface material properties and the introduction of residual stress. But above all, the process is known to be one of the most effective and widely employed processes meant to increase component durability.

2. Heating prior to deformation: forging, swaging, upsetting, bending, and piercing.

3. Brazing and Soldering: brazing of steel, brass, and copper to each other in combination and aluminum to aluminum.

4. Shrink fitting: In any manufacturing process, for example, shrink fitting of motor rotors to shafts, shrink fitting of shell casings for compressors.

5. Coating: Of dissimilar metals, prior to insulation, and curing, such as paint.

6. Melting: Of all types of metals.

7. Other applications include crystal growing, cap sealing, sintering, carbon vapor deposition, levitation, exit axial deposition, and plasma generation.

ADVANTAGES OF INDUCTION HARDENING

Dramatic energy savings due to process efficiency

Minimal distortion

Higher throughput and productivity

Superior precision and unrivaled repeatability

Easy automation and incorporation into existing production lines

Welcome to GY

GY had developed many years of research and is committed to

providing customers with all kinds of medium frequency, high

frequency, super audio frequency,ultrahigh frequency induction

heating equipment, and automation equipment. We provide solutions

for project planning, development, design, manufacturing and

comprehensive after-sales service according to your needs. One-stop

solutions for customer heat treatmen tneeds.The lates tDSP+FPGA

all-digital control system products provide more professional, more

accurate solutions and personalized high-quality products for many

users on the road of innovation, transformation and transformation

break throughs.

From 1996, devoted

For more than 27 years, GY has always been adhering to the company

philosophy of innovation, adherence to quality and excellent

operation. A single R&D office researches a single product.

After more than 20 years of hard work, it has developed steadily.

The current equipment users cover many industries such as

manufacturing, electric power and nuclear power,government science

reform, university scientific research, and special military

industry. In view of the different voltage levels

in some countries, the company has developed special input voltage

induction heating equipment for different frequency parameters. For

example, the input voltage suitable for use i n the United States,

Japan and other countries is single-phase 110V, three-phase 110V,

three-phase 220V, and three-phase 480V. Heating equipment and

heating equipment with input voltage of three-phase 415V and

three-phase 440V suitable for use in Southeast Asian countries such

as Malaysia, Australia and Thailand Inheritance builds trust.

Inherit and build trust

Made in China is facing global competition and challenges. To find

a suitable position in the international and domestic markets and

open up a larger market, we must use more advanced technology and

good after-sales service to improve ourselves. We will always be

committed to the application and promotion of GY series products in

the market with the spirit of pursuing professionalism, excellence

and perseverance, and seek cooperation with suppliers, agents and

users with professional technical support and good business

collaboration. Common development and progress.