Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

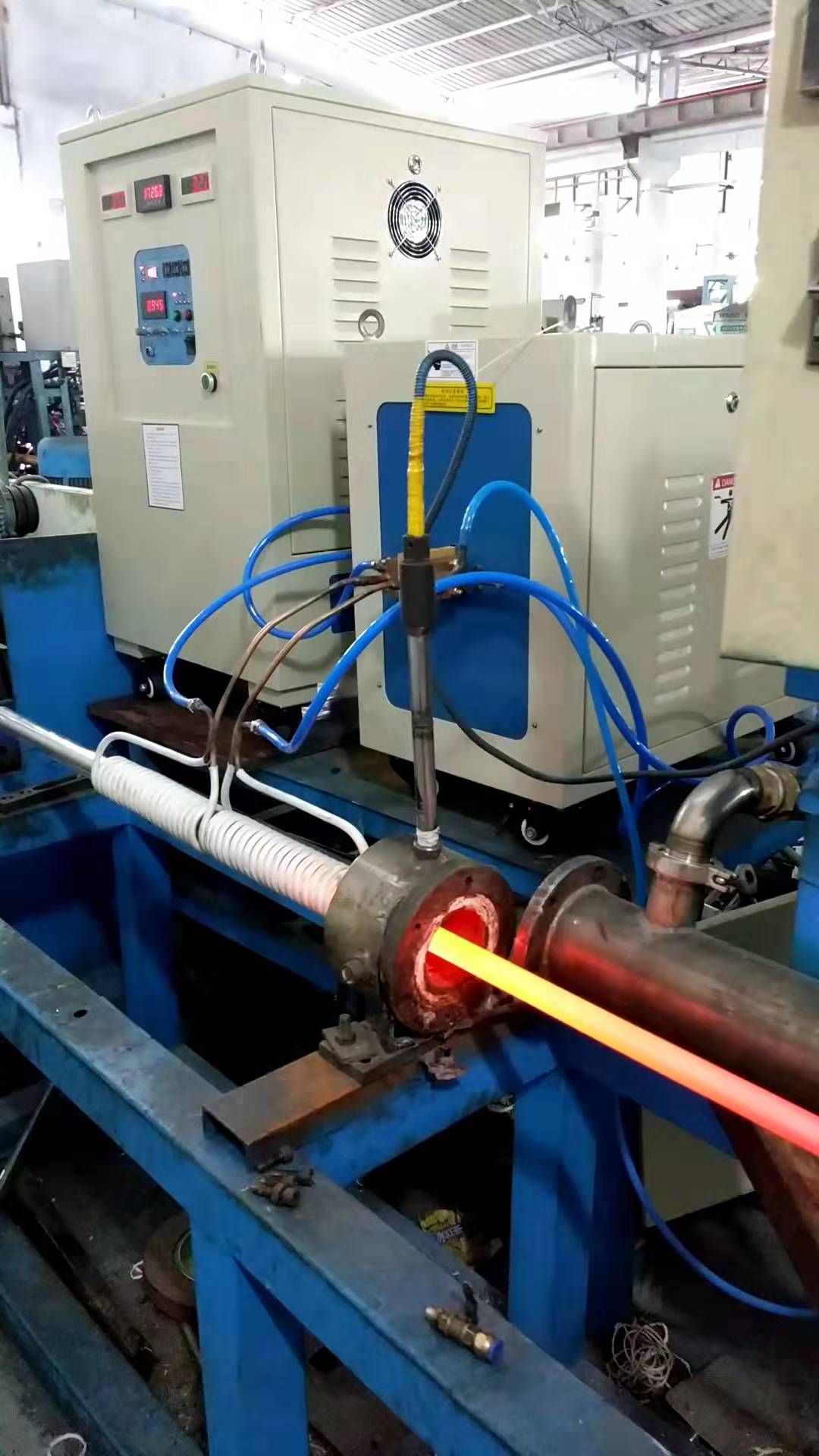

Steel Bar Heating Induction Hardening Machine For Surface Quenching

Induction hardening is a process used for the surface hardening of steel and other alloy components. The parts to be heat treated are placed inside a water cooled copper coil and then heated above their transformation temperature by applying an alternating current to the coil. The alternating current in the coil induces an alternating magnetic field within the work piece, which if made from steel, caused the outer surface of the part to heat to a temperature above the transformation range. Parts are held at that temperature until the appropriate depth of hardening has been achieved, and then quenched in oil, or another media, depending upon the steel type and hardness desired.

Quick Detail:

| Name | 160KW Induction Heating Machine for Stainless steel online annealing

| Application | Stainless steel online annealing |

| Work power | 340V-430V | Out power | 160KW |

| Product size | main : 1000x695x1100mm | Certificate | CE,SGS |

| transformer : 870x430x750mm |

Technical Parameters:

| Model | GYS-160AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 240A |

| Output power | 160KW |

| Fluctuating frequency | 10-50KHZ |

| Output current | 400-6500A |

| The flow rate of cooling water | 0.08-0.16Mpa 15L/Min |

| Water temperature protection point | 50C |

| Product size | main : 1000x695x1100mm |

| transformer : 870x430x750mm | |

| Net weight | main : 155kgs |

| transformer : 95kgs |

MAIN CHARACTERISTICS OF THE 160KW INDUCTION HEATING MACHINE:

1. 160KW Induction Heating Machine for Stainless steel online annealing adopts the most advanced MOS, IGBT frequency conversion control technologies to ensure the high efficiency and maximum output power.

2. 160KW Induction Heating Machine for Stainless steel online annealing it has the constant current and power control function, which can significantly optimize metal heating process, realize the high efficient and fast heating and bring into play the superior performance of the products.

3. 160KW Induction Heating Machine for Stainless steel online annealing has the function of three-stage time setting represented by heating-heat preservation-cooling. Furthermore, the power for heating and heat preservation is available for independent regulation, which can facilitate the heating and heat preservation, which is applicable to places requiring bulking and repeated heating.

4. A maximum ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

5. It is safe and reliable, and requires no equipments of ten thousand voltage, and thus can ensure the safe operation.

6. The comprehensive full load design is available for 24-hour continuous operation.

7. 160KW Induction Heating Machine for Stainless steel online annealing is available for ultraviolet temperature detection, which can realize the automatic control of temperature, improve the heating performance and simplify the manual operation.

Annealing (tempering and modulation):

1. Annealing of various stainless steel products, such as stainless steel basin, annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

2. Annealing of various other metal work pieces, such as golf ball head, cue, brass lock, hardware copper fitting, kitchen knife handle, blade, aluminum pan, aluminum pail, aluminum radiator and various aluminum products.

Our services

Pre-sale service.

In-sale service.

After-sale service.