Jiangyin M&C Heat Parts Co.,Ltd |

|

Verified Suppliers

|

|

Titanium 0.5mm Material NT250L Plate Heat Exchanger Plate For Sea Water Fluid

Plate Heat Exchanger Introduction

| No. | Component | No. | Component |

| 1 | Upper Support Rod | 9 | HE plates |

| 2 | Profile Support Rod(Optional) | 10 | Initial Plate |

| 3 | Threaded Rod | 11 | Support Angle |

| 4 | Frame Cover | 12 | Connections |

| 5 | Support | 13 | Frame Head |

| 6 | Lower Support Rod | 14 | Nut |

| 7 | End Plate | 15 | Channel Gasket |

| 8 | Support Foot(Optional) | 16 | Initial Gasket |

NT250L Model Plate Heat Exchanger Specification

| Surface Area | 1.38㎡ |

| Plate Theta Angle | Horizontal 124 ° Vertical 124° |

| Connection Diameter | 250 mm |

| Plate Corrugate Thickness | 3.1 mm |

| Plate Centre Length* Width | 2000*420 mm |

| Plate Shape Length*Width | 2330*745 mm |

NT250L Plate Heat Exchanger Technical Information

| Model | Connection Size | Dim. A | Dim.B | Dim.C |

| NT250S | 10" nominal (DN250) | 35.2" (895mm) | 89.5" (2273mm) | Up to 159" (4039mm) |

| NT250M | 99.6"(2529mm) | |||

| NT250L | 112.8" (2866mm) |

| Heat Transfer Plate | 316L Stainless,304 Stainless, Titanium, Hastelloy, 904L, SMO254 and others on request |

| Gasket | NBR, EPDM, Viton and others on request |

| Pressure Plate | Carbon Steel, Stainless Steel and others on request |

| Port Connection | Unlined, Metal Lined (Stainless, Titanium and others on request), Welded Neck Flange, threaded nipple and others on request |

| Maximum Design Pressure | Maximum design pressure is 300 psig(21 bar). Depending on application. |

| Maximum Design Temperature | Maximum standard design temperature is 330 °F (170 °C).Higher temperatures are available on request. |

| Approximate Maximum Liquid Flow Rate | NT50:175 gpm (40 m³/hour) NT100: 830 gpm (190 m³/hour) NT150:1540 gpm (350 m³/hour) NT250:3960 gpm (900 m³/hour) NT350:8380 gpm (1900 m³/hour) NT500:20,000 gpm (4000 m³/hour) |

The HE plate pack consists of individual embossed HE plates with

the asso- ciated HE plate gaskets.

The HE plate gaskets seal the flow media towards one another and

the envi- ronment.

The number and the arrangement of HE plates depends on the

requirements specified in the order.

| No. | Component | No. | Component |

| 11 | WT plate profile | 13 | Leakage spaces |

| 12 | HE plate gasket | 14 | Round gasket sections |

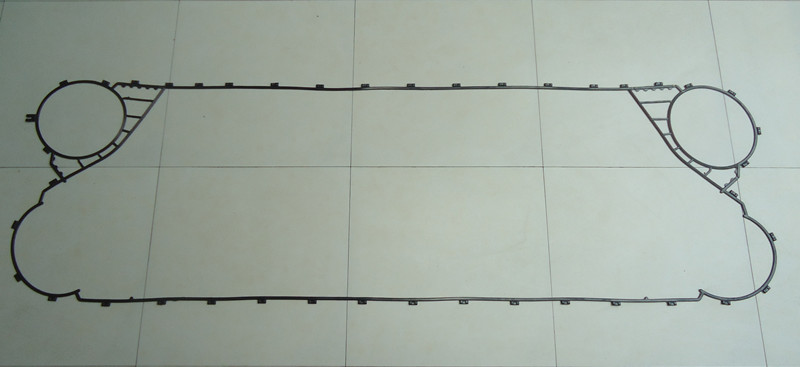

NT250L Plate Heat Exchanger Gasket & Plate Pictures

NT250L Plate Heat Exchangers Application And Benefits

Application:

With M&C Heat Parts product group, the NT series is a gasketed plate heat exchanger for multiple applications. Variety of materials that work across a broad range of liquids, temperatures and pressures. Well-suited for these liquid-to-liquid applications:

| HVAC | Chemical | Sugar | Marine |

| Food | Renewable Energy | Power |

Benefits:

Versatility-

Higher Performance at a Lower Cost -

Convenient Maintenance-

Long Service Life-

Plate Heat Exchanger Leak Conditions And Solutions

When the HE plate pack is tensioned to less than tensioning dimension a min., the HE plates are damaged. The PHE may become leaky and flow media can escape.

Environmental damage due to leaks

Damage to PHE by sudden pressure rise (liquid hammer ) or sudden pressure drop (cavitation hammer)

When the flow velocity of a flow medium changes, a liquid hammer or a cavitation hammer may occur. This can damage the PHE and flow media can escape.

Damage to PHE due to freezing of flow media

Leaks when putting multi-stage PHE into and out of operation

When putting multi-stage PHEs into and out of operation and failing to pressurize or relieve all sections evenly, the tensioning dimension may be exceeded in individual sections. This may produce leaks.

Plate Heat Exchanger Commissioning

Initial commissioning of the PHE is to follow the conditions below: Before starting PHE commissioning, ensure

Ensure that operating conditions are so

Safety instructions:Commissioning at very low ambient temperatures

If you wish to commission or re-commission the PHE at very low

ambient temperatures, M&C Heat recommends to heat up the PHE

slowly to the oper- ating temperature, using the flow media.

Safety instructions:Commissioning of multi-stage PHE

Ensure that when commissioning multi-stage PHE, all sections must

be pressurized or relieved evenly.

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is specialized in designing and manufacturing high quality heat transfer equipment. The range of products comprises plates & gaskets, plate heat exchangers, gasketed heat exchangers and brazed heat exchangers. Thus, as one of the few producers worldwide, M&C offers solutions with optimum thermodynamic designs for different industries and virtually all applications.

M&C provide you with one-stop accessories service, multuple-brand & multiple model alternatives for your choice. We'll meet all your requirements of plate heat exchanger and keep your machine running contunously through our rich storage and quick response.

Moreover, we have a strict quality control and after-sales service system, from material purchasing to finished product package until the product received in good condition. Our products have been widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81, S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107, K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64, GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma 36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90 and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135, RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M, NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70, FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so on;

M&C Plate Heat Exchanger Goods ready to Delivery