Jiangyin M&C Heat Parts Co.,Ltd |

|

Verified Suppliers

|

|

S8/S8A Sondex/Danfoss Plate Heat Exchanger For Small-Sized

Pasteurization Used in Food Industry

S8/S8A Plate Heat Exchanger Design Principle

The type S4A and S8A plate range with lengths up to 0.75m (2.5 ft) and a "long" thermal pattern will cover many duties up to 6 m³/h (26 gpm) in a single pass solution, meaning that all the connections are on the head side, This will ensure easy pipe- and service work, and by dismantling the exchanger for service, no pipes need to be removed.

This plate range is designed for a small-sized pasteurization up to 3.000 l/h (depending on the type of product and the temperture profile) and ensures a gentle and soft product treatment.

The heat transfer is obtained, when the warm medium transfers energy through the thin, strong flow plates between the channels and delivers it to the cold opposing medium without mixing the two media. Counter-current flow creats the optimal efficiency. The plate- and inlet design allows effective,easy CIP (Cleaning in Place) of all "flow" surfaces.

S8/S8A Model Plate Heat Exchanger Specification

| Surface Area | 0.08㎡ |

| Plate Theta Angle | Horizontal 130° Vertical 130° |

| Connection Diameter | 28mm |

| Plate Corrugate Thickness | 2.35 mm |

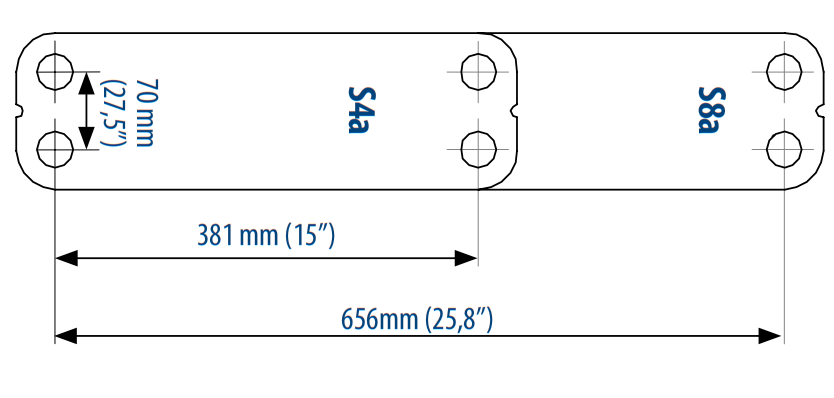

| Plate Centre Length* Width | 656*70 mm |

| Plate Shape Length*Width | 724*140 mm |

S8/S8A Plate Heat Exchanger Gasket & Plate Pictures

S8/S8A Frames

| Number of Plates | L(frame length)(mm) | W(mm) | H(mm) | Weigth max,empty(kg) | Connection type |

| S8A FG16 | |||||

| 7-19 | 275 | 200(7.87") | 758(29.84") | 74 | DN25/1" Dairy Union |

| 20-30 | 325 | 79 | |||

| 31-53 | 425 | 92 | |||

| 54-76 | 525 | 105 | |||

| S8A FS16 | |||||

| 7-55 | 448 | 200(7.87") | 913-943(35.95"-37.13") | 77 | DN25/1" Dairy Union |

| 56-75 | 548 | 83 | |||

| 76-95 | 648 | 109 | |||

| 96-124 | 798 | 140 | |||

S8/S8A Plate Heat Exchanger Technical Data

| Type | S1 | S4A | S6A | S8A | ||

| Max. working pressure | PN (bar) | 10.16 | ||||

| Max. operating temperature | °C | Up to 180 | ||||

| Min. operating temperature | -10 | |||||

| Flow medium | Water and different fluids, steam | |||||

| Volume/channel | I | 0.09 | 0.17 | 0.13 | 0.21 | |

| Connection size | DN32/1.25" | |||||

| Connection type |

| |||||

| Plate material |

| |||||

| Plate thickness | mm |

| ||||

| Gasket material |

| |||||

| Gasket attachment type | Sonder Lock | |||||

| Liners in connections |

| |||||

| Frame |

| |||||

| Frame painting specification | Painting available for corrosion categories C2L, C4M, C5M | |||||

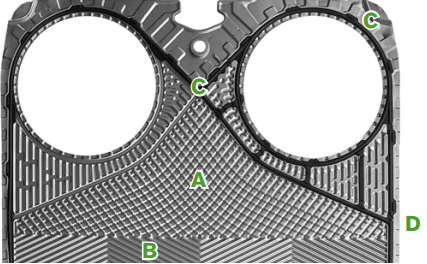

PHE Plate Feature

| FEATURE | ADVANTAGES | WHAT'S IN IT FOR YOU! | |

| A | DISTRIBUTION AREA | Efficient Flow Distribution |

|

| B | CORRUGATED PLATE PATTERN-HEAT TRANSFER AREA | Promotes Turbulence, Minimize Fouling |

|

| C | PLATE LOCKING SYSTEMS | "Corner lock" and " bubble lock" concepts ensure a stable and well aligned plate pack when the unit is closed |

|

| D | EASYCLIP GASKET SYSTEM | Bevelled gasket edges easily clip into place using your flingers Stays securely in place and provides high sealing integrity |

|

PHE Gasket Type

Please check their are three common model gasket type are aways used in Sondex brand.

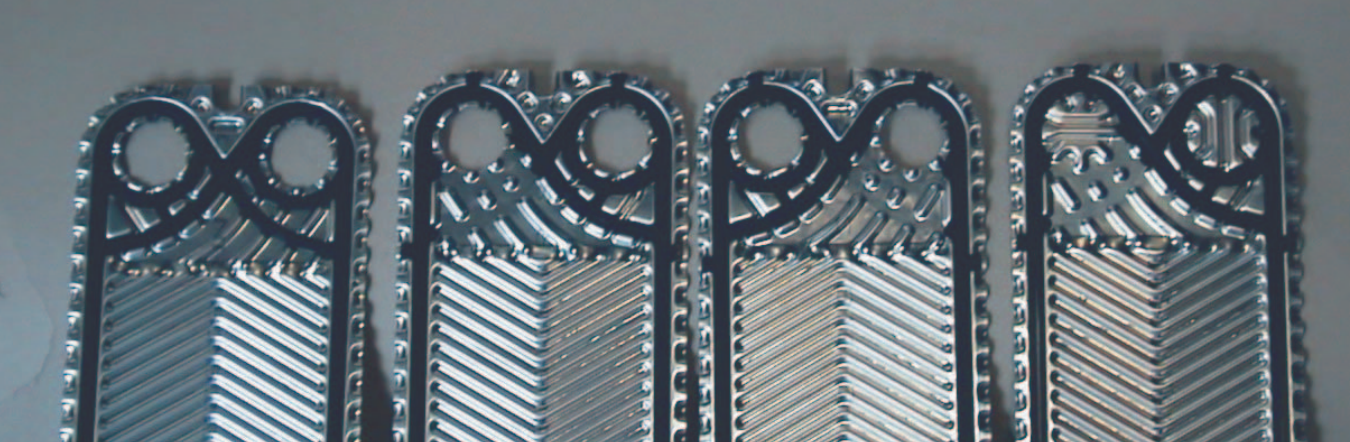

PHE Plate Type

"Start plate with gasket""Left hand flow plate with gasket""Right

hand flow plate with gasket" End plate with gasket"

Thermal Long Plate Thermal Short Plate

PHE Problem Solving

If you have problems with your plate type heat exchanger, in most cases these can be solved by your own personnel. Please find below a summary of possible problems as well as possible causes and solutions.

A condition for the continuous proper functioning of your plate type heat exchanger is in strict compliance with the permissible values for pressure and temperature mentioned on the name plate.

Exceeding these values, even as a short-lasting pressure peaks will cause damage to the unit and be the cause of problems.

To avoid costly repairs, we advise you to have the installation work and maintenance carried out by properly trained personnel. You can also contact us.

| Problem | Possible Cause | Possible Solution |

| Leakage | At the connections |

|

| Mixing of primary and secondary circuit |

| |

| In plate package |

| |

| The operating Conditions deviate from the specification |

| |

| Insufficient Capacity | Air in the system |

|

| The operating conditions deviate from the specification |

| |

| The heat exchanger is dirty |

| |

| The connections have been interchanged |

| |

| Too high pressure drop | Flow large the design flow |

|

| Channels in plate(s) blocked |

| |

| Incorrect measurements |

| |

| Medium deviating from the design |

| |

| Air in the system |

|

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is specialized in designing and manufacturing high quality heat transfer equipment. The range of products comprises plates & gaskets, plate heat exchangers, gasketed heat exchangers and brazed heat exchangers. Thus, as one of the few producers worldwide, M&C offers solutions with optimum thermodynamic designs for different industries and virtually all applications.

M&C provide you with one-stop accessories service, multuple-brand & multiple model alternatives for your choice. We'll meet all your requirements of plate heat exchanger and keep your machine running contunously through our rich storage and quick response.

Moreover, we have a strict quality control and after-sales service system, from material purchasing to finished product package until the product received in good condition. Our products have been widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81, S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107, K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64, GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma 36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90 and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135, RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M, NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70, FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so on;

M&C Plate Heat Exchanger Goods ready to Delivery