Shenzhen Hanwei Laser Equipment Co., Ltd. |

|

Verified Suppliers

|

|

* Multi functions integrated in one unit.

* Laser Welding 0.5-5mm.

* Laser Cleaning 0.5-50mm.

* Laser Cutting Handheld cutting type.

* Easy to swith between different work mode.

* Easy to replace lens.

* Easy to replace nozzles.

* Easy to set parameters.

In metal processing, welding is a widely used process, which can be seen in various industries, from carbon steel and stainless steel to copper and aluminum alloys. At present, the most commonly used one is arc welding. Electric welding machines have penetrated into various factories and workshops, as well as roadside metal processing stores. They are used in kitchenware, bathroom, door and window guardrails, etc. The number of electric welding machines sold for thousands of yuan per set is millions.

However, traditional electric welding has some drawbacks, which have led to some young people choosing to work in the welding industry less and less. The emergence of handheld laser welding precisely overcomes the shortcomings of traditional electric welding and provides an alternative choice. Therefore, in recent years, the demand for handheld laser welding has been very hot.

Comparison between laser welding and traditional welding

| NO | Parts Name | Advantages | Defect | Fiber laser welding compare |

| 1 | CO2 Welding | Low Price | Use High cost | Use low cost |

| 2 | CO2 Welding | Welding thick material | Welding surface is roughness, with lots of following processing. Not suitable for welding thin material | Welding surface is smooth, with few following processing. Suitable for welding thin material |

| 3 | CO2 Welding | Use wire as consumable parts | Wire as option. | |

| 4 | CO2 Welding | Use CO2 protection gas | Use argon or nitrogen as protection gas | |

| 5 | Argon welding | Low price, Use middle cost | Welding speed is slow. | Use low cost, Welding speed is fast 2-3 times than argon. |

| 6 | CO2 & Argon | Difficult operation | Easy operation | |

| 7 | CO2 & Argon | Low safety | High safety | |

| 8 | CO2 & Argon | High technical requirements to the operator. With high costs. | Technical requirements to the operator are not too much. With low costs.

|

There is still some space for reduce purchasing cost of handheld laser welding equipment, but it will not match the thousands of level ordinary welding machines. Laser welding will continue to replace traditional welding machines in the application market, and can maintain a demand of over 150000 units per year, becoming a more popular equipment model in the metal processing field.

Overall, handheld laser welding has the characteristics of high efficiency, energy conservation, and environmental protection. While continuously replacing traditional welding processing methods, it improves the overall efficiency and environmental performance of the entire society.

| Model | Three-In-One Handheld Laser |

| Usable Laser Power | Up to 2000w |

| Welding Area | 0.5-5mm |

| Cleaning Area | 0.5-50mm |

| Cutting Method | Handheld Cutting |

| Handheld Head Weight | 0.7 kg |

| Laser head size | 216*287 mm |

| Laser head packing size | 39*22*29cm. |

| Laser head packing gross weight | 9kg |

| Standard single route wire feeding device packing Info | 17Kg. 70*40*65cm. |

| Double route wire feeding device packing Info | 30Kg. 79*45*70cm. |

| Usable laser source | Most of laser source |

2. Ease of Use: The integrated design of the Three-In-One simplifies the setup and operation of the laser welding process,laser cleaning process,laser cutting process. Operators can quickly switch between different working tasks without the need for extensive adjustments or equipment changes. This ease of use enhances productivity and reduces downtime between working operations.

3. Versatility: The three-in-one design offers versatility in terms of applications. It can be used for various welding,cleaning,cutting tasks. The ability to adjust the laser beam parameters and optimize the optics system allows for customization according to specific requirements.

4. Precision and Quality: The precise control provided by the laser source and optics system ensures high-quality welds with minimal distortion or damage to the workpiece. The focused laser beam allows for narrow and deep welds, resulting in strong and aesthetically pleasing joints. The handheld nature of the welding head also enables better operator control, leading to improved weld consistency and accuracy.

5. Increased Efficiency: The combination of portability, ease of use, and precision results in improved efficiency in laser welding operations. The three-in-one design minimizes setup time, reduces the need for rework, and enhances overall productivity. The cooling system also contributes to efficiency by maintaining optimal working conditions and preventing overheating-related interruptions.

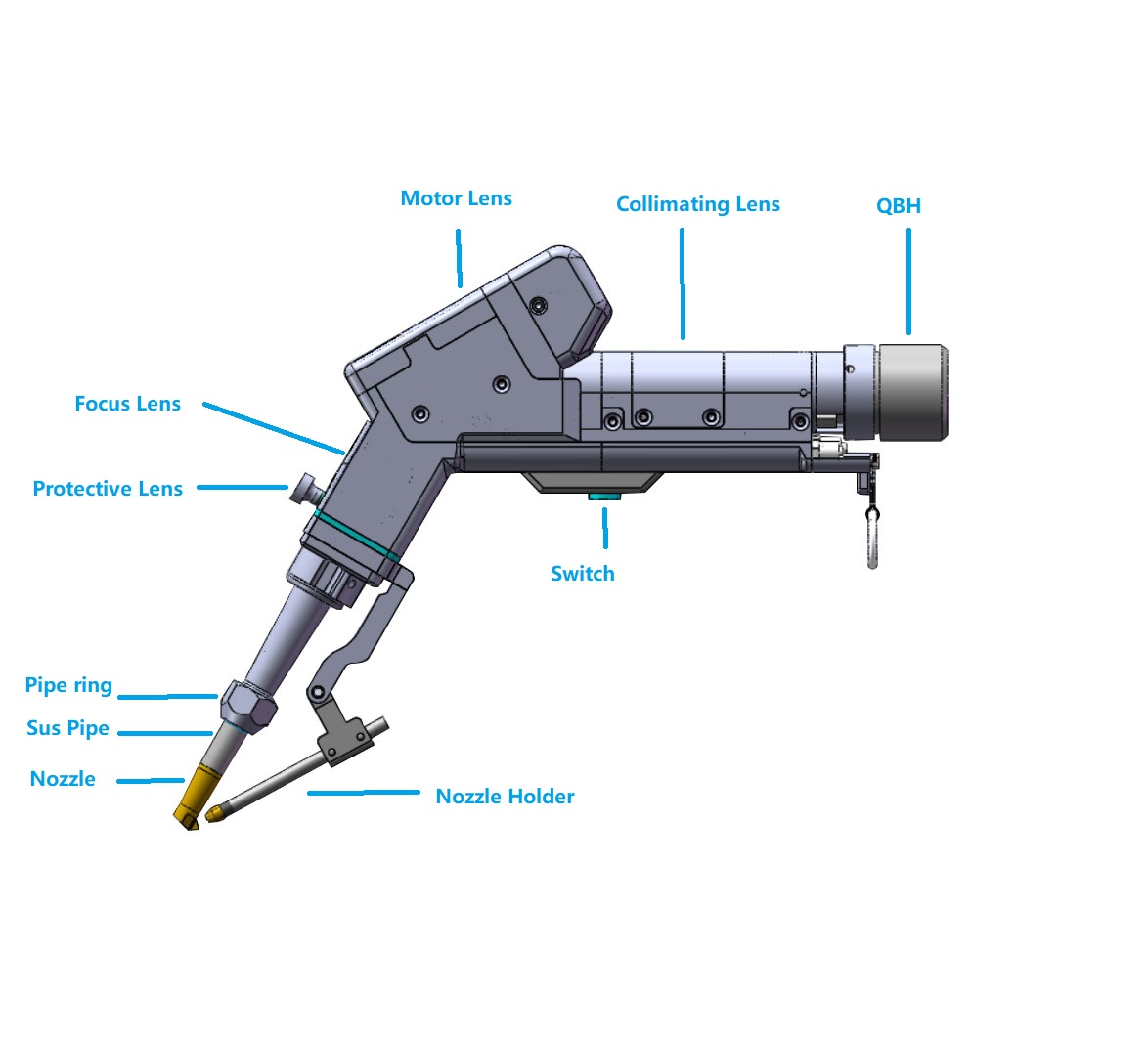

Handheld Welding Head Product Show:

Handheld Laser Head Three-In-One. Extremely Light in weight and small volume,adopt streamline ergonomic design make holding operation is comfortable.

Control System : Torch monitor. The control system is very easy and requires little prior knowledge on the part of the operator.

Laser welding head, control system, monitor, power supply and spare parts. With safety lock function to ensure safety process.

Standard single route wire feeding device

Dual route wire feeding device. Support Dual route wire same time feeding, welding bead up to 12mm. And also can switch any one route to use as single route wire feeding.

Paper Box Packing

Welding Sample Show

Nozzle

Lens and Mirrors : Protective lens, Focus lens, Motor lens, Collimating lens.