FOSHAN STAR TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

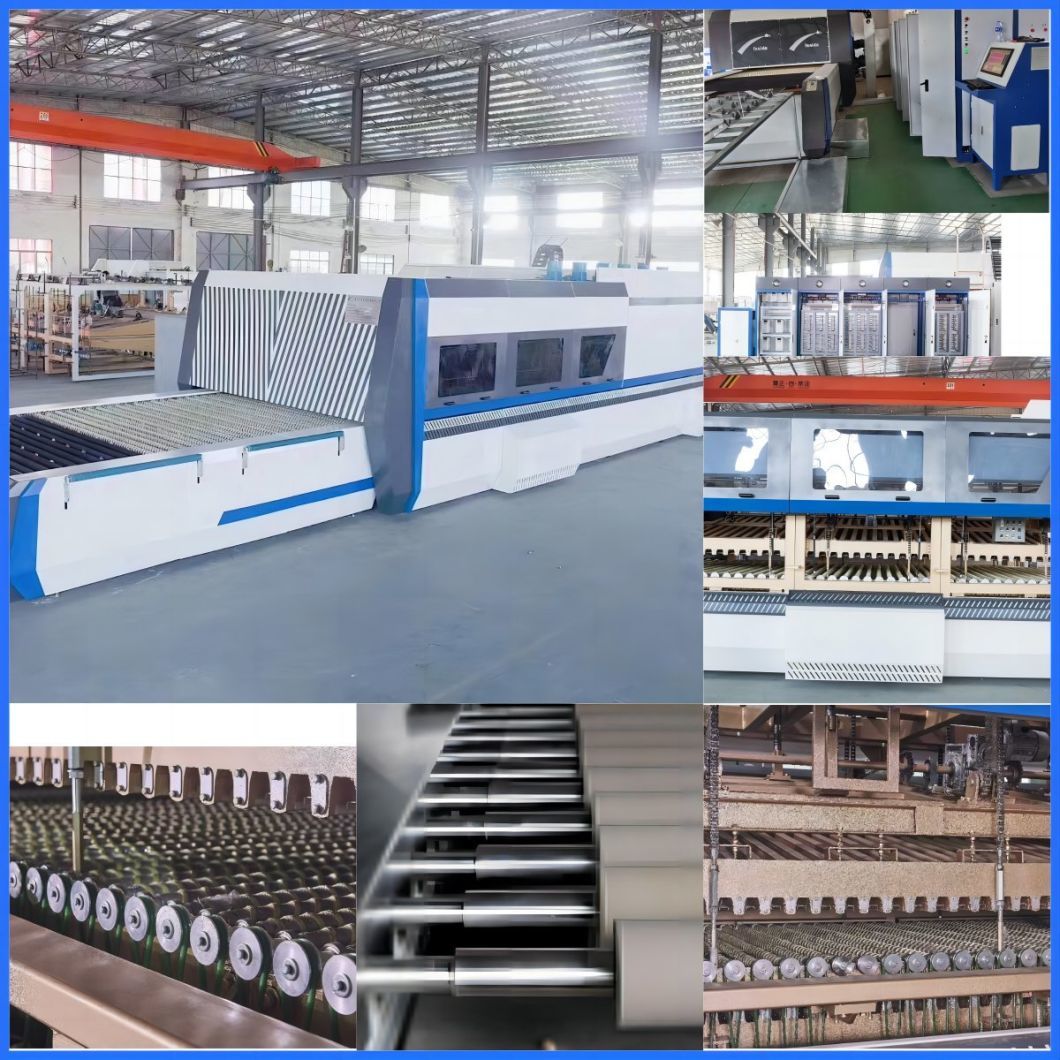

| Model | STG-ABQ-2442-4T | ||

| Flat Glass | Max loading area | 2440 x 4220mm | |

| Min Glass size | 250x300mm | ||

| Glass thickness range | 4-19MM | ||

| Max glass size | 2440x4220MM | ||

| Bend Glass | Max glass size | 2440x2000(Arc length) MM | |

| Glass thickness | 4-12MM | ||

| For size | Two position(two glass heat ) | ||

| Radius &thickness | R≥1000mm(5~6mm) R≥1500mm(8~10mm) R≥2000mm(12mm) | ||

| Bend adjustment system | Bend adjustment by special type of Hydraulic system,for high accuracy bending. | ||

| Parameter for Hydraulic | 11KW, 21Mpa | ||

| Heating methods | Top and bottom full forced air convection model | ||

| Requested glass quality |

| ||

| Power | Heating | 600KW | |

| Blower | 280KW+90KW | ||

| Drives | 27KW | ||

| Transformer requirement | ≥630KVA | ||

| Recommended transformer capacity | The power capacity may be different and should be referring to the actual | ||

| Blower Control | controlled by frequency inverters | ||

| Quality Standard | ANSI Z97.1-2004, | ||

| Finished product rate | ≥ 98% | ||

| Installation period (approximately,) | 15 working days | ||

| Commissioning period (approximately) | 10 working days | ||

| Training period (approximately) | 10 working days | ||

| Guarantee period | ONE year for non worn-out parts and components. | ||

| Power supplier mode | To order | ||

| Glass thickness (mm) | Glass tempered cycle. (Load/hour) | Note | |

| FLAT GLASS | 4 | 18-22 | The size, producing area and color of glass panel will cause the production difference. The production of glass plate with small size and deep color will be slightly larger. |

| 5 | 16-18 | ||

| 6 | 14-16 | ||

| 8 | 10-12 | ||

| 10 | 9-10 | ||

| 12 | 7-8 | ||

| BEND GLASS | |||

|  |