JEFFER Engineering and Technology Co.,Ltd |

|

Verified Suppliers

|

|

15ml 30ml 60ml Amber Color Glass Bottle Production Line Dropper Bottle

1. Brief introduction

15ml 30ml 60ml Amber Color Glass Bottle Production Line Dropper Bottle is mainly made of soda-lime glass, and the color of the glass is usually clear (flint), amber and green. If the customer requires the one furnace to produce multiple colors of products such as pink, blue, yellow, etc., it can be achieved through special forehearth coloring technology. With its good chemical stability and excellent sensory vision, glass container product is the most widely used packaging containers in the food, beverage and other industry.

Glass melting is a very complex process, it includes physical, chemical and physicochemical phenomena and reaction. These phenomena and reaction lead the mechanical mixed raw materials to complex melting glass liquid.

The defect of glass production is mainly due to the melting process, the melting quality has a close relationship with the quality of yield production, production cost, fuel combustion, furnace campaign, etc. It is important to ensure the physicochemical reaction of batched materials perform well during the whole melting process, and make sure the whole process is smoothly operated and for manufacturing high quality glass products.

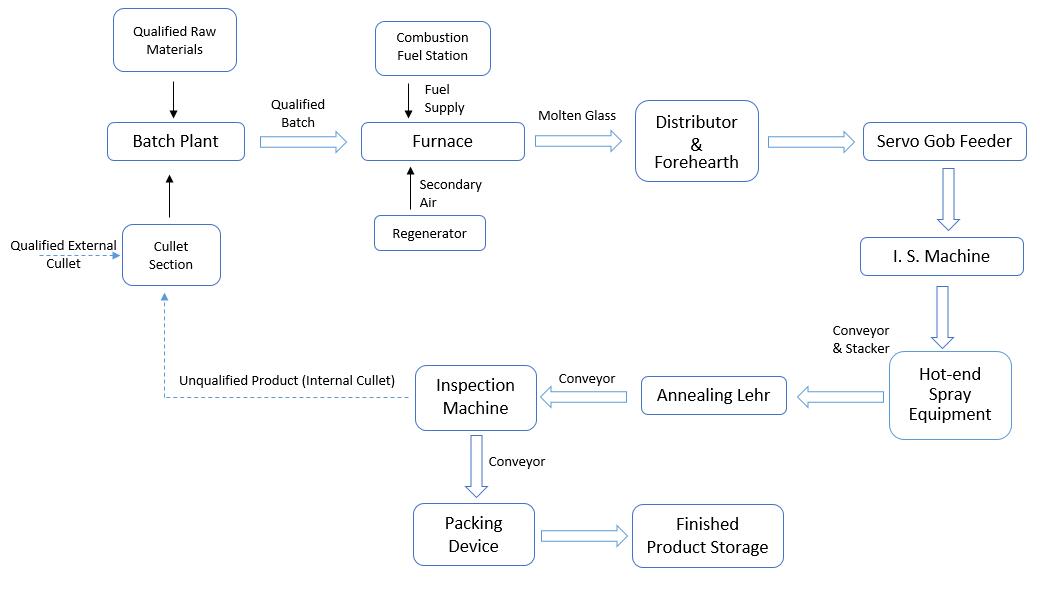

2. Typical Techncial Process

The techncial process of glass bottle making is descripbed as the following,

We can supply different kinds of heating type furnace. Including:

4. Techncial Features

6. Packing and delivery

All the equipment shall be carefully and properly packed, and shall meet the requirements of ocean and inland transportation.

7. FAQ

Q: Can you custom the product?

A: Yes, we design the production line based on the requirement of

the client.

Q: How do you control the quaility?

A: All our processes are strictly combined with ISO standard. And

our professional team will supervise the quality control during the

design and manufacture.

Q: If we need skilled workers, how can we solve this issue?

A: JEFFER Engineering can provide the training service to the

client, our engineers will train the workers on site.

Q: Why choose JEFFER?

A: 1. Professional in this area over 30 years.

2. Excellent technical team.

3. Strictly quality control

4. Professional and coniderate service