Mechanical Technology Co.,Ltd |

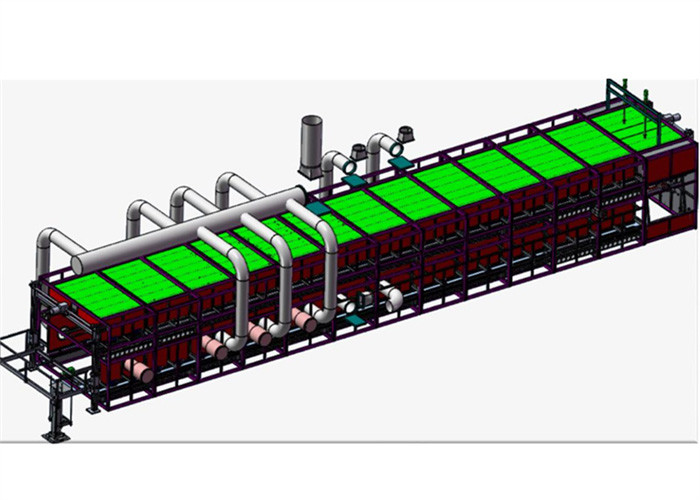

Continuous Hot Bending Furnace For Automobile Glass Car Bus And Truck Forming

1. PURPOSE/DESCRIPTION OF PROCESS

This Continuous Hot Bending Furnace For Automobile Glass Car Bus And Truck Forming is a melting machine for automotive laminated front windshields glass, During the manufacturing process, the glass is heated and bent under high temperatures into the required shape, then cooled. All processing steps are done via computer control, ensuring an ultra-high accuracy.

It adopts Automatic temperature control, The glass preheating zone, hot bending zone, and annealing zone all adopt automatic temperature control devices, which is convenient for the operator to control and reduce operator errors. Smart meter display, easy to set temperature, heating control can be manual or automatic, easy to fine-tune.

It has the features of,

2. APPLICATION

Bending - Car, Bus, Truck & Train

3. PRODUCTION CAPACITY

The transfer speed for FZL6-2360: 310 pcs/8Hrs

4. DESCRIPTION

4.1 Structure

This Automobile Glass Bending Machine Continuous Heating And Annealing is composed mainly of:

4.2 Technical Parameters

| MODEL | MAX.GLASS SIZE (mm) | GLASS THICKNESS (mm) | DEEPTH OF BEND (mm) | CAPACITY 8/H (PCS) | POWER (KW) |

| FZL4-2000 | 2000*1000 mm | 4-6 | 250 | 400 | 1200 |

| FZL5-2200 | 2000*1250 mm | 4-6 | 250 | 360 | 1450 |

| FZL6-2360 | 2360*1250 mm | 4-6 | 250 | 310 | 1600 |

| FZL5-2200 | 2000*1250 mm | 4-6 | 250 | 550 | 1800 |

| Voltage/Frequency | 380V/50Hz 3ph (Adjustable according to the customer) |

| PLC Voltage PLC | 220V |

| Control Voltage | 24VDC |

| Voltage Variation | +/-10% |

| Temperature | 18℃~35℃ |

| Humidity | 50%(Max≤75%) |

simple operation

High efficiency

Energy saving

6. PACKAGE AND SHIPPMENT

7. LAYOUT (REFERENCE)

8. RELATED PROCESSING LINE MACHINES

9. OUR SERVICE

9.1 Pre-sale Service

FUZUAN's professional technical team will provide you with an all-round and timely service before you make the final decision. It includes,

9.2 After-sale Service

FUZUAN will provide you complete and systematic after-sale service,which can deliver its

technology service quickly to reduce equipment

malfunction possibility and shorten downtime. It includes:

10. COMPANY BRIEF INTRODUCTION

FUZUAN is located in Rong Yang Industrial Zone, Xishan District, Wuxi, Jiangsu Province China, we mainly provides professional ONE-STOP glass solution for Automotive Glass, including the Laminated & Tempered Processing Lines for vehicle, such as cars, trucks, passenger cars,cart, bus etc. and we are a high-tech enterprise integrating production, R&D, technical service and sales,with our technological expertise and strong focus on successful implementation, we develop solutions that make the difference, for our customers.

FUZUAN 's main service customers includes AGC, SAINT-GOBAIN, VITRO, PGW, FUYAO GROUP, SYPK AUTOGLASS, XINYI GLASS, TM GLASS, WYP AUTOMOTIVE, AFG AUTO GLASS etc, all major professional glass enterprises in China and overseas.

Our main products including:

Many different kinds of Auto glass loading machine, before Bando/Bystronic Line and other process,

Automatic raw glass cutting line N/1 before Bando/Bystronic Line,

Automotive glass pre-processing line,

Glass Cutting, breaking, grinding line, CBGD, full aotomatic type and semi-automatic type,

CNC grinding machine,

Glass drilling machine,

Glass washing and drying machine, both for flat glass and curved glass,

Talcum Powdering machine,

Glass screen printing line, includes the printing machine and the drying machine after printing,

Vacuum pre-laminate machine,

PVB assembly conveyor line,

PVB Stretching and Cutting machine,

Glass bending furnace,

Automatic large/small size glass match machine,

Lamination glass stacking machine,

Automatic conveyor line,

Terminal solding machine, Automatic welding machine

PVC Pre-heat line,

Online resistance and optics detection machine,

Various kinds of glass inspection machine, Tension, resistance, thermal break line detection machine,

Complete set of assembly tooling machine etc.

It can be customized according to the special needs of customers', provide and transformation of various standard automotive glass processing equipments and non-standard equipment.