AAC is a lightweight foam silicate product. The main materials are

based on silicon materials (sand, fly ash, gangue)

Silicon and calcium (cement and lime), mixed with foaming agent

(aluminum powder), after batching and mixing,

The process of pouring, pre curing, cutting, and steam

(high-pressure sterilization) ultimately produces this lightweight

concrete product.

Classification:

AAC classification: Generally, it can be classified based on the

type of raw materials, manufacturing process, and function.

According to the shape of AAC products, they can be divided into

AAC blocks and AAC panels.

Advantages:

AAC is a revolutionary material with high durability and strength,

low weight, excellent insulation, fire resistance, sound

absorption, unprecedented construction ability, and outstanding

ecological green functions. AAC is one of the earliest and most

widely used lightweight wall materials in China.

1. Raw materials processing

Put the fly ash or sand into the ball mill to mill via the conveyor

belt, after milling, put the slurry into the slurry storage

tank by slurry pump.

2. Batching, mixing and casting

The lime, cement will convey by conveyor to the dry powder measure

scale to scale separately. The slurry convey by slurry pump

then to the automatic scale;the power and slurry put into the

mixer,pouring into the mould.

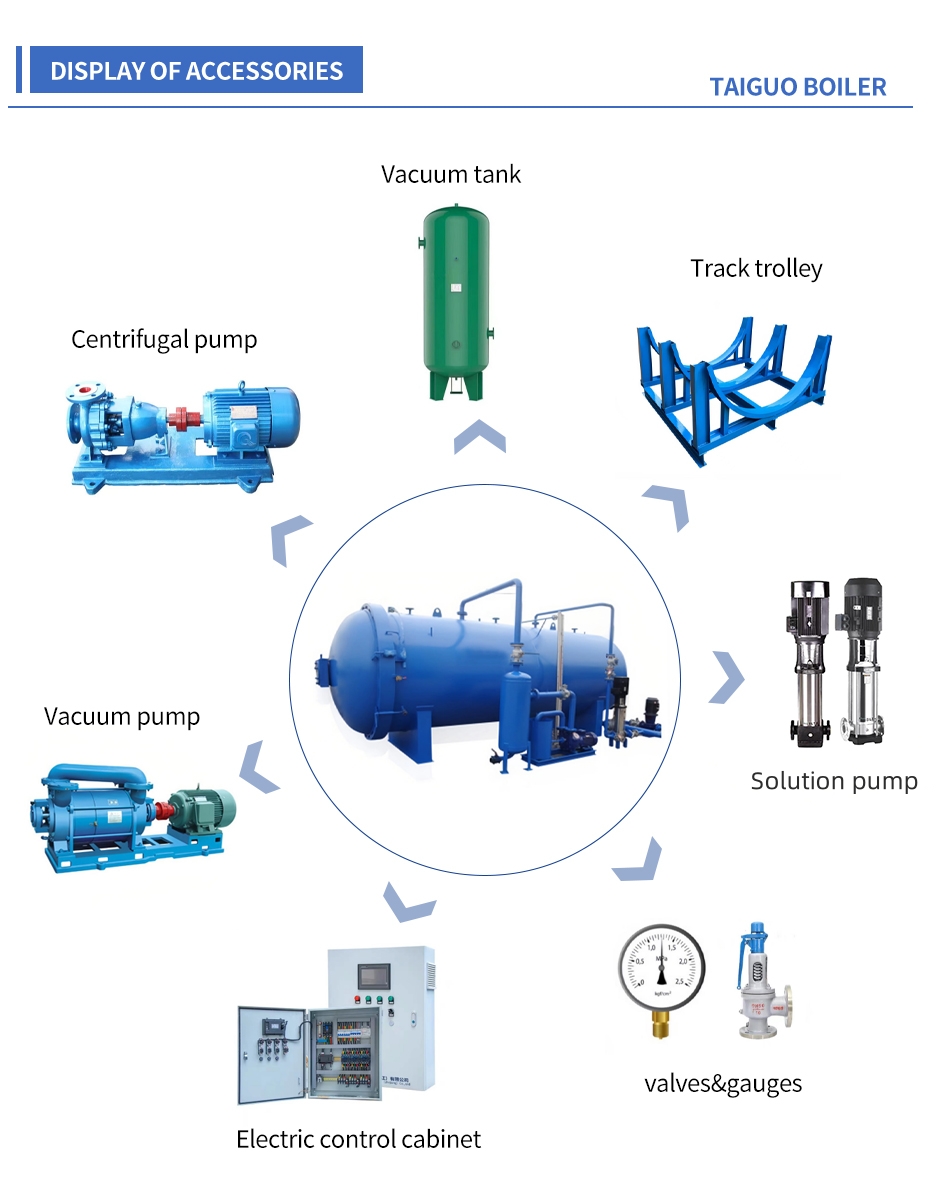

3.Steaming

Finished cutting using semi-product crane carry to the front of

autoclavegrouped,hoisting machine or dragger will drag steam

trolley into autoclave to steam,it need 10-12 hours.