Basic on the Sendzimir tech of Annealing Pickling Line with

open flame furnace

JJRS, Established in 2011 at Beijing in China, is leading Exporter,

Manufacturer, Supplier of Furnace Manufacturers in China. JJRS is

one of verified and trusted sellers of listed products. With their

extensive experience of supplying and trading Continuous Annealing

Furnace, JJRS has made a reputed name for themselves in the market

with high quality Continuous Annealing Furnace etc.

Focusing on a customer centric approach, JJRS has a pan-India

presence and caters to a huge consumer base throughout the country.

Technical specifications of annealing furnace

This heat treatment process has the advantages of high quality,

high efficiency and low consumption. It is equipped with NOF double

cross limiting control, detection of combustion atmosphere during

operating, pulse heating and double cross limiting automatic

control heating of radiant tube heating section, furnace pressure

closed loop and furnace temperature closed loop, which can ensure

stability of furnace combustion state, furnace atmosphere and safe

operation.

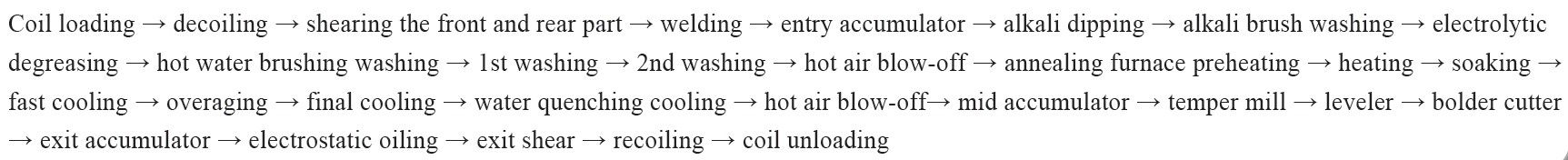

The horizontal continuous annealing furnace is composed of the

following sections: inlet sealing chamber, open fire heating

furnace( including preheating section), middle sealing chamber,

radiant tube reduction furnace(including soaking zone), forced

cooling section, baffle, strip temperature equalizing section,

furnace nose (including hot tensioning chamber). The total length

from the inlet chamber to the zinc pot is about 151 meters.

After the strip passes through the hot tensioning roll, the tension

inside and outside the furnace is cut off, which can improve the

tension outside the furnace and is beneficial to the control of the

coating by the subsequent air knife. The steel strip is sealed into

the zinc pot by the furnace nose inserted into the zinc solution. A

radiating thermometer is set in the furnace nose for detecting and

controlling the temperature of the steel strip at the outlet.

Continuous Annealing Furnace Features

- Applicable to large volume production of single variety

- Short annealing period and high productive efficiency

- Good temperature uniformity and good surface quality of finished

product

- Complicated technology with large one-time investment

- JJRS self-developed " JJRS-Sendzimir" technology with lots of

technical patents

- Energy cyclic utilization saves running cost and decreases

annealing cost

- Fuels applicable for wide us: Natural gas, cooled coal gas,

blast-furnace gas, coke oven gas, etc.

- Advanced furnace structure, perfect heat preservation, even and

stable temperature control

- Higher-level automation could realize automatic control, automatic

detection, safety protetion, automatic report and long-range

control etc.

Technical Parameter| Heated steel type | cold rolled and hot rolled common carbon steel; |

| Fuel | natural gas (lower calorific value ≥8430×4.18kJ/Nm3) |

| Steel strip size | maximum width: 520mm; Thickness: 0.7-2.9mm; |

| Maximum TV value | 120mm·m/min |

| Furnace temperature in heating section | 1050 ~ 1180℃; |

| Maximum output per hour | 29.39t/h |

.

.

.

.